KFWELD Electrical Technology Co., LTD |

|

KFWELD exothermic welding materials is to melt the metal conductor through the high temperature produced by the oxidized metals in the reductive flux during the exothermic reducing reaction. This series of products include exothermic welding mould, mould Handle clamp, exothermic welding flux and supporting operation tool kit.

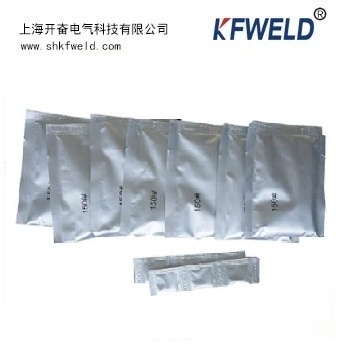

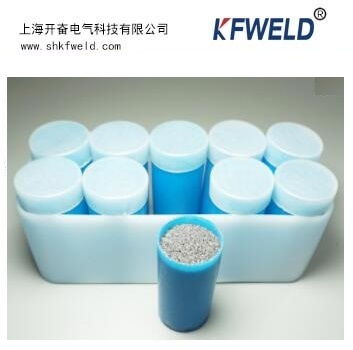

KFWELD weld power is a mixture of copper oxide and aluminium , packaged by size in individual plastic tubs or bags.

KFWELD exothermic welding product was certified by UL, RoHS, CE and compliance with IEEE Std.80, UL467 and IEEE837. It has the national invention patent ZL200410021807X. KFWELD has stable ignition point, good conductivity and corrosion protection and excellent tensile strength. After improved process, the connector is more bright and clean.

Exothermic welding powder specification:

| Part No. | Specification | Part No. | Specification |

| KFWELD-65P10 | 65#,65gram | KFWELD-200P10 | 200#,200gram |

| KFWELD-90P10 | 90#,90gram | KFWELD-250P10 | 250#,250gram |

| KFWELD-115P10 | 115#,115gram | KFWELD-300P10 | 300#,300gram |

| KFWELD-150P10 | 150#,150gram | KFWELD-400P10 | 400#,400gram |