Gnee (Tianjin) Multinational Trade Co., Ltd. |

|

Verified Suppliers

|

|

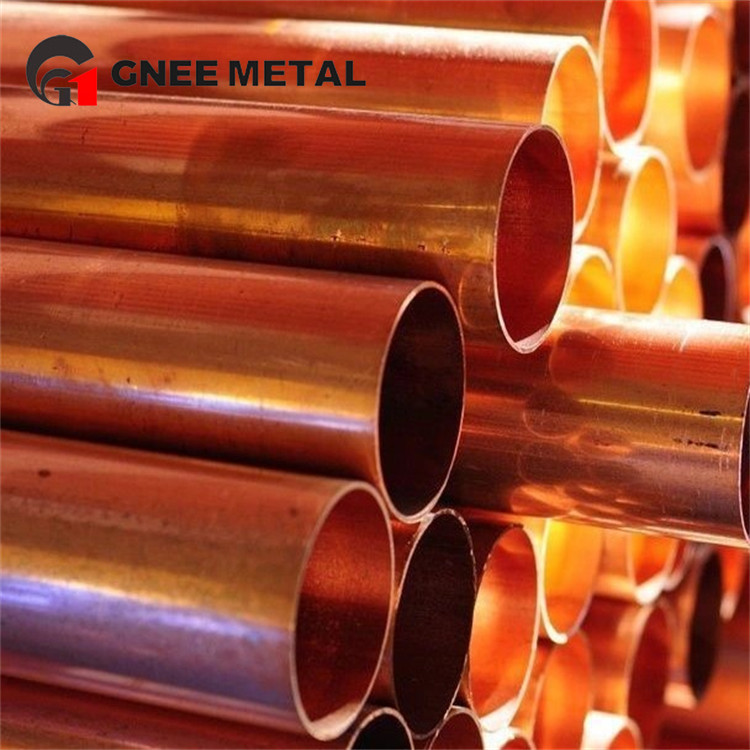

C2800 copper pipes are commonly used in refrigeration systems due to their favorable properties, including good thermal conductivity, corrosion resistance, and ease of fabrication. Here are some specific applications of C2800 copper pipes in refrigeration systems:

Condenser Coils: Copper pipes are often employed in the construction of condenser coils in refrigeration systems. Condenser coils release heat from the refrigerant to the surrounding environment, and copper's high thermal conductivity ensures effective heat dissipation. The pipes are typically coiled or arranged in a specific pattern within the condenser unit.

Evaporator Coils: Copper pipes are also used in the construction of evaporator coils, which are responsible for absorbing heat from the surroundings (e.g., air, water, or other fluids) to cool the refrigerated space. The high thermal conductivity of copper aids in efficient heat absorption.

Capillary Tubes: Capillary tubes are often used as expansion devices in refrigeration systems to regulate the flow of refrigerant into the evaporator coil. Copper's excellent machinability makes it suitable for manufacturing capillary tubes with precise dimensions.

Suction Lines: Copper pipes are employed as suction lines to return the refrigerant from the evaporator coil to the compressor. These lines need to withstand the low-pressure conditions and potential temperature variations encountered in this part of the system.

| Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard. | ||

| Surface | Polished,bright,oiled,hair line,brush,mirror,or as required | ||

| Package | Plastic film with Wooden case or wooden pallet | ||

| Delivery time | Prompt delivery or upon your order quantity. | ||

| MOQ | Negotiable | ||

| Quality Control | Mill Test Certification is supplied with shipment,Third Part Inspection is acceptable. | ||

| Shape | Round | ||

Thank you for choosing us as your copper supplier. We would like to provide you with information about our copper packaging process to ensure that your order arrives safely and in optimal condition.

At our company, we prioritize the proper packaging of copper materials to protect them from damage during transit. Here is an overview of our copper packaging procedure:

Copper tubes and pipes are packaged to safeguard their shape and prevent bending or deformation. They are typically wrapped individually with protective material such as bubble wrap or foam sleeves. These individually wrapped tubes are then bundled together and secured with strapping or shrink wrap. Additionally, we use strong cardboard boxes or wooden crates to provide additional protection.