Shenzhen Xianheng Technology Co.,Ltd |

|

Verified Suppliers

|

|

Factory CNC Machining Customize Communication Equipment Accessories CNC Machining Accessory Supplier

Xiange Technology Co., Ltd. was founded in Shenzhen in 2003, which is professional in CNC Machining Accessory, CNC Fabrication Parts, Metal Stamping Parts and Metal Sheet Fabrication.

We are one of the CNC Machining Accessory Supplier, our processing

ranges involve CNC Machining Parts, CNC Fabrication Parts, 3D

printing parts, metal stamping parts, metal fabrication, metal

forging parts, die casting parts.

We have 2000 sq. ft factory including 3D printing equipment, CNC

milling/turning machines, Automatic lathe machines,

Stamping/bending machines, Laser cutting machines. We services 650+

customers all over the world. We have global strategy and develop

our business to the United States, Canada, Germany, UK, Japan,

Australia and other countries and regions.

Existing product testing equipment, Image measuring instrument,

Height instrument, Roughness Tester, Micrometer, Torque test, Salt

spray test, Hardness testing equipment, Provide a strong guarantee

for high-quality products.

Specifications

1.OEM & ODM

2.Item Name: Communication Equipment Accessory

3.Available Materials: Stainless Steel,Steel,Aluminum,Brass,Copper,Wooden Etc

4.Processing Service: 3 4 5 6 Axis CNC Machining Service , CNC Turning Service,CNC Milling Service And Other Mold Processing Service

5.High Quality: Various Testing Equipment To Ensure The Quality

6.Competitive Price: Different Processing Combination Can Be Used To Reduce Costing

7.Other Products: CNC Machining Accessory,CNC Milling Parts,Machining Lathe Parts,Metal Stamping Parts,Rivets Etc

8.Large Quantity Production Capacity

9.Short Delivery Time

10.RoHS Compliant For All Our Communication Equipment Accessory

Advantages

1. Quality control: the defective products rate is 0.1%. Imported material 100%.

2. Reasonable price. Precision made. Experience & reasonable QC that you can reply on.

3. Each part would be given 100% test and tryout before shipment.

4. Adequate supply capacity. Punctual delivery time.

Q: How can I customize my products ?

A: Please describe your project. Include the following information so that we can provide an accurate quote: Part Name, 3D CAD Drawing, Quantity, Material, Color, Finishing.

Q: How can I know my products going on ?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the production process.

Q: Can You sign a confidentiality greement ?

A: We can sign a confidentiality agreement according to your needs.

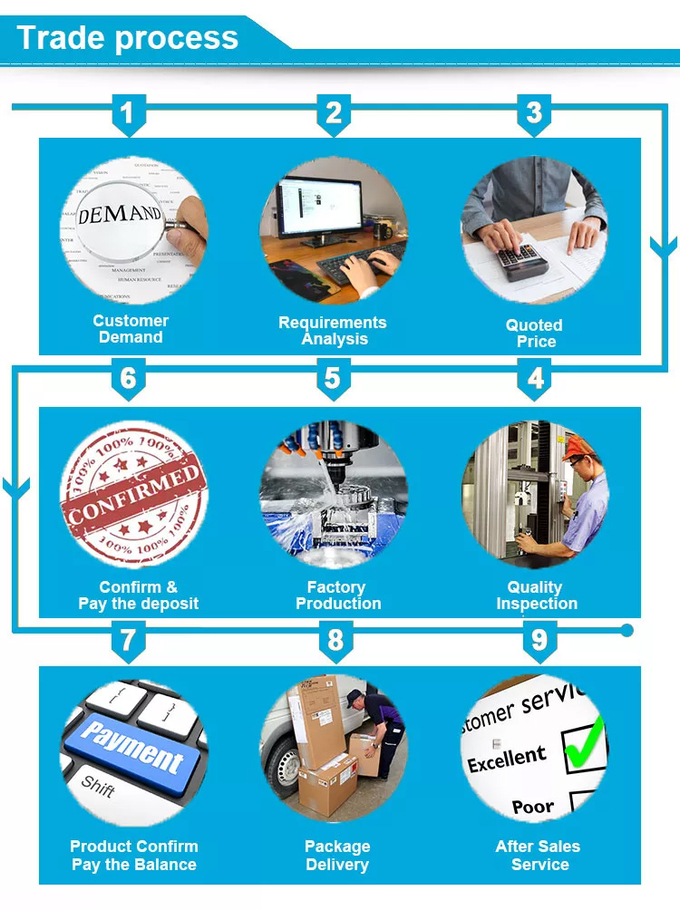

Q: What is your terms of payment ?

A: 30% in advance ,70% balance before shipment. Other terms negotiable.

Q: Are you a trading company or factory?

A: We are direct factory with 20 experienced engineers and more than 80 employees as well approximate 3,000 square meters workshop area.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.