Shenzhen Xianheng Technology Co.,Ltd |

|

Verified Suppliers

|

|

Customized Sheet Metal Housing Shell for Electric Equipment Large Electronic Control Box Enclosure Factory

We can supply a full-range of mechanical products, such as aluminum die casting parts,sheet metal fabrication, cnc machining parts, casting parts, aluminum profile, plastic/rubber parts,assembly. Product market range cover auto industry, medical industry,agricultural machinery, sport industry and so on.

| Material available | Carbon steel (CRS/SPCC, SECC,etc),Stainless steel, spring steel, Bronze (berylium, phosphor, etc), brass, copper alloy, aluminum alloy, tinplate, nickel silver, cold roll steel, hot roll steel, zinc plate, or custom |

| Metal processing available | CNC lathe milling, CNC lathe turning, drilling, tapping, CNC finishing, CNC laser cutting, flame cutting, punching, stamping, pressing-folding, bending-welding-CNC machining, drilling-welding-spray, tapping, bending and forming,coating-assembling-packing |

| Surface Finished: | Powder Coated, Hot Galvanized, Painting, Polishing, spray coating,

Brushing, Cataphoresis, sandblasting, electroplate Chrome/Zinc/Nickel Plating/Anodize/Electronic Polish, Silk-screen etc; |

| Specification | OEM/ODM, according to customer's drawing or sample |

| Tolerance | Stamping parts:0.01-0.1mm, CNC machining parts:0.1-0.002mm |

| Files Formats: | Pro/Engineer, Solidworks, Auto CAD,Pro/E, Solidworks, Unigraphics |

| Major Equipment: | TRUMPF LASER CUTTING MACHINE; |

| CNC SHEAR MACHINE; | |

| CNC PUNCHING MACHINE; | |

| CNC BENDING MACHINE; | |

| TIG WELDING MACHINE; | |

| MIG WELDING MACHINE; | |

| SPOT WELDING MACHINE; | |

| ROLLING MACHINE; | |

| PIPE BENDER; | |

| STAMPING MACHINE; | |

| Product include | Sheet Metal Shell steel parts, Metal chassis, metallic cabinets, metal cabinets, metal cases, metal enclosures, metal boxes metallic machinery casing, metallic communication products, metallic auto parts, metallic refrigerator parts, metallic washing machine parts, vending machine shell fabrication, communication cabinet fabrication, mold designing making and so on. |

| Test | CMM,Digital Height Gauge, caliper, Coordinate measuring machine, roughness test, hardness test. etc |

| Packing | Inside: packed with plastic film to protect each piece Outside: by waterproof craft paper or EPE film in wooden case |

Equipments&Facilities

| High Speed Punching Machine | CNC Punching Machine | CNC Bending Machine |

| Laser Cutting Machine | CNC Wire EDM | Sheet Metal Shearer |

| Hydraulic Deep Drawing Machine | CNC Machining Center | Polishing Machine |

| Welding Machine | Wire Drawing Machine | CNC Lathe |

| Leveling Machine | Precise Die Casting Machine | Grinding Machine |

Metal Working Service

| CNC Machining | Laser Cutting | Custom Metal Welding | CNC Metal Bending |

| CNC Turning | Rapid Prototyping | Sheet Metal Fabrication | Metal Deep Drawing |

| CNC Milling | Casting&Forging | Surface Finishing | Metal Punching |

Custom Metal Solutions

| Candle Holders/Cups | Medical Containers | Metal End Covers | Mobile Phone Shells |

| Crafts Stamping Parts | Tablewares | Aluminum Lids | Cabinet Enclosures |

| Lighting Stamping Parts | Filters/Strainers | Cosmetic Caps | Furniture Accessories |

| Metal Brackets/Stands | Protective Shields | Essential Oil Caps | Door&Window Fittings |

| Electronic Components | Sheet Metal Panels | Perfume Caps | Shafts/Sleeves/Gears |

| Electrical Connections | Cooling Fins | Wine Bottle Caps | Fasteners |

| Metal Structures | Metal Contact Clips | Jar Caps | Machinery Parts |

| Car Spare Parts | Motor Spare Parts | Glass Bottle Caps | Pipe Fittings/Elbows |

OUR ADVANTAGES

1: Specialized in various metal part and mould part producing, CNC Machining, and Metal Stamping, Forging and Casting

2: All international standard materials can be available, carbon steel, alloy steel, stainless steel, brass, aluminum and plastic etc

3: All kinds of finish treatments can be available, like power coating, hard anodizing, zinc plated, plating, oxidation, blasting, painting, anodizing, heat treatment etc

4: We have good cooperation companies, we make good use of outsourcing some factories and equipment, like heat treatment, large boring machine etc, so we can digest large order

5: Sample is ok for confirmation before mass production

6: QC inspect after products finished

7: Before package, we will choose the best way to avoid the unnecessary damages during transportation

Why are you choose us ?

1) We have our own factories, quality can be controlled seriously.

2) We Specialize in manufacturing about 21 years.

3) We have professional testing department and testing equipment.

4) We have 12 rich experience engineers & 20 senior technicians.

5) Timely delivery and excellent service.

6) We believe Reasonable price = High quality + Best service.

Q1: Could you give me your best price?

A1: Of course yes, we are a professional manufacturer, so we could supply the best price without many middlemen.

Q2: If my quantity is very small, could you do my products?

A2: Yes, we can. Do not worry about the quantity. We will provide different production ways based on your quantity.

Q3: How long would the delivery time?

A3: It is based on all of your requirements about the products.

Q4: How can you guarantee the quality?

A4: We have a powerful QC team to control the quality in every production process. We believe the best quality is our enterprise life.

That’s why we have lots of big group companies.

Q5: I want to buy your products, how can I make the payment?

A5: We can accept the T/T, western union.

Q6. How to keep your product quality?

Quality is our lives, we have technical worker and quality

department to check all material and every step from the very

beginning to ensure the quality of our products.

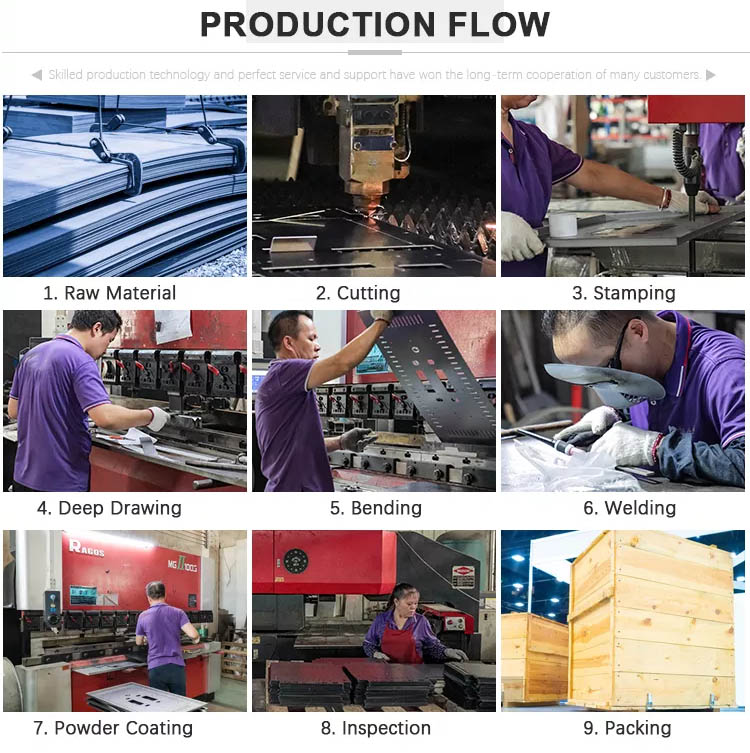

Here is the working flow of our QC System:

1) Confirm all drawings with customer and confirm the best

production method.

2) Check the raw material before coming into our warehouse.

3) Confirm the samples, reports of material and specs with

customer.

4) Keep checking every production line, including each production

process and the working condition of each machine.

5) 100% full inspection before packing them.

6) Check the package before delivery.

.