BOTOU SHITONG COLD ROLL FORMING MACHINERY MANUFACTURING CO.,LTD |

|

Verified Suppliers

|

|

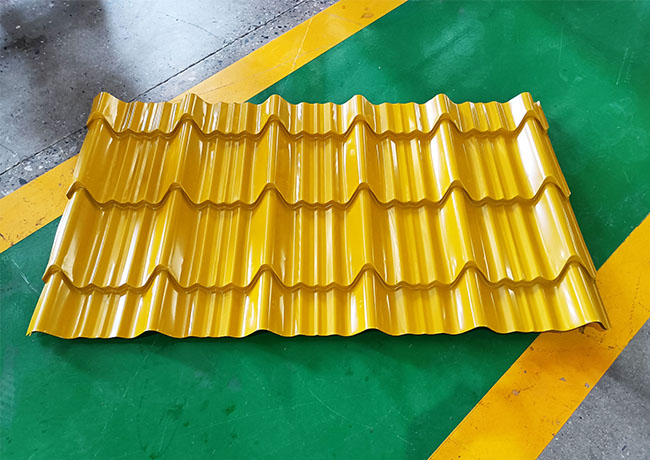

Customized PLC Control Roof Tile Glazed Tile Roll forming Machine

Roof Tile

1. Customized PLC Control Roof Tile Glazed Tile Roll forming Machine

Roof Tile

1. More than 10 years experiences in manufacturing&exporting

roll forming machines.

2. We use Automatic control software to manage productive

information makes the whole automatic control system has an

improvement in automaticity.

3. High performance in operation, maintenance, and debugging. Easy

to load and unload.

4. Good machine quality, Competitive price and Fast delivery time

and superior service.

2. Customized PLC Control Roof Tile Glazed Tile Roll forming Machine

Roof Tile Parameters:

| (1) 5Tons manual un-coiler | |

| Description | There are different choices, please turn to the catalogue of un-coiler |

| (2) Entry bench & Manual Pre-shearing device | |

| Function | Smart cut control, to cut off the end of the final piece of sheet only |

| Shearing Thickness | Up to Max. 0.8mm (if thickness > 0.8mm, then hydraulic pre-shearing device or electric pre-shearing device instead ) |

| (3) The general machine parameter | |

| Suitable roll forming material | Color steel sheet or Aluminum |

| Thickness | 0.4mm-0.6mm |

| Feeding width | 1219mm |

| Frame design | Wall-plate-frame-design /New-stand-frame-design |

| Roll stages | 18 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ75 mm |

| Main motor power | 7.5KW with reducer |

| Max. Line speed of roll former | Approx. 4m/min (stair length 350mm, production length 6m) |

| Hydraulic Stair-Drawing & Cutting Device | There is one hydraulic press to make the stair according to requirement and hydraulic post cut for cut off |

| Hydraulic group power | 11KW |

| Material of cutting blade | Cr12, heat treatment |

| Electric Standard | 380V /50Hz/3PH or as the customer's requirements |

| Machine Dimensions | 9430mm×1960mm×1650mm |

| Major Color of Machine Painted | RAL 5015 (Blue) or as per customer's requirements |

Decoiler--Manual prectting--Material Guiding--Roll forming M/C--Hydraulic System--Post Cutting--Exit Rack

This machine takes GI/PPGI as raw material, through a series steps

and can produce the barrel type roofing sheets.

The inverter controls the motor speed, the PLC system controls

length and quantity automatically, therefore, the machine achieves

a continuous automatic production, which is the ideal equipment for

cold roll forming industry.

A. If buyers visit our factory and check the machine, we will teach

you how to install and use the machine, and also trainyour

workers/technician face to face.

B. Without visiting, we will send you user manual and video to

teach you to install and operate.

C. If buyer needs our technician to go to your local factory,

please arrange board and lodging and other necessary things.

1. How to get the quotation?

1.1.Give me the profile drawing and thickness,this is the important.

1.2 Other specific requirements is welcome,such as the speed,power

and voltage you want.

1.3 If you don't have your own profile drawing, we can recommend

some model types according to your local market standard.

2.Do you have after sales support?

Yes, we are glad to support advice. Our technicians available

across the world.

3. Why your price is higher than others?

As we persist on that each factory should put quality at the first

place. We spend a lot of time and money in the research and development of

equipment and material selection, so that our machine is more

automated, more reliable and accurate, and has a higher service

life. Our equipment can last for nearly 20 years, and we offer a

two-year warranty.

4. What can we do if the machine broken?

The machine will be tested before shipment with coil, ensure

everything is ready 2.We will prepare some spare parts along with

the machine, ensure our customer can solve the issue in a shortest

time.Both the sale person and technician can give you the service

overseas and make training for the workers,the sale person can make

translation, so that the installation and training will be more

clear and easily.