Jiangyin Dingbo Technology Co., Ltd |

|

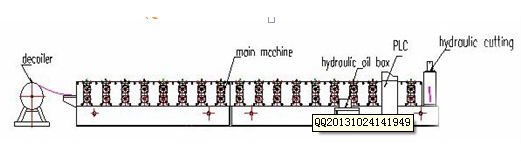

three layer corrugated and ibr metal roof sheet cold roll forming machine

This producing line uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate. The products are used as the roof tile and wall panel outside of building, as well as decorative sheet and ceiling board inside of building, to increase the beauty and durability of the roof tile and wall panel.

1.Term of payment: TT, 40%TT should be paid as advanced deposit ,60%TT before shipment .

2.Delivery time: Within 35 working days after received of the deposit

3.After-service:Engineer available to service machinery onerseas

CE ISO SGS certification

1. Standard packaging: Main machine is naked. Computer control

system is packed by carton box.

2. Need a 40GP to ship.

1. advantage of three layer roof panel roll forming machine

This kind of machine make three types of tile together perfectly, it has reasinable structure, beautiful appearance, with advantage of saving space, easy operate and especially welcomed by the costomer with limit area or site operation.

2. Main Parameter and specification of the Three layer roof panel roll forming machine

We design each machine according to user requirement. Below techinical parameters can be adjusted if needed.

1.control system: automatic PLC frequency control ,text screen.

2.roller steps:12/18 rows

3.main power:5kw

4.pump power:4kw

5.Diameter of roller: Φ80mm

6.max speed:12m/min

7.feeding width:1250mm

8.the effective width:925/1080mm,tolerance ±1/100

9.thickness of the plate:0.35-0.8mm

10.the dimension of main roll former: 8600mm×1300mm×1450mm

11.roller material:45#steel,CNC-machined ,heat treatment, buffing,

surface for electroplating chromium 0.05mm