Shanghai Strong Metal Production Co., Ltd. |

|

Verified Suppliers

|

|

Plastic Injection Molding Injection Molding For Plastic Products ManufacturPlastic Injection Molding

1 Injection-molded copper nuts

The process of microcellular foaming can be divided into three stages: firstly, supercritical fluid (carbon dioxide or nitrogen) is

dissolved into hot melt glue to form a single-phase solution; Then, the mold cavity with low temperature and pressure is

shot through the switch nozzle. Due to the molecular instability caused by the decrease of temperature and pressure,

a large number of bubble nuclei are formed in the product, and these bubble nuclei gradually grow into tiny holes.

2 Technical Parameters

| Product name | Plastic Injection Molding Injection Molding For Plastic Products ManufacturPlastic Injection Molding |

| Item | Mig Welding Thin Sheet Metal Laser Cut Steel Plate Sheet Metal Fabrication Plastic Injection Molding |

| Color | Black,White, as customers' requirement |

| Mould life | 250900-300000shots, |

| Size | Customized Size, |

| Mold life | 000 to 1, 500000 shots, |

3 Product Details

Use: Electronic locker

Function: This is a part which used in electronic locker and we can

see there is a number block on the surface of it,

and also facial recognition

Technology: plastic injection, burr remove

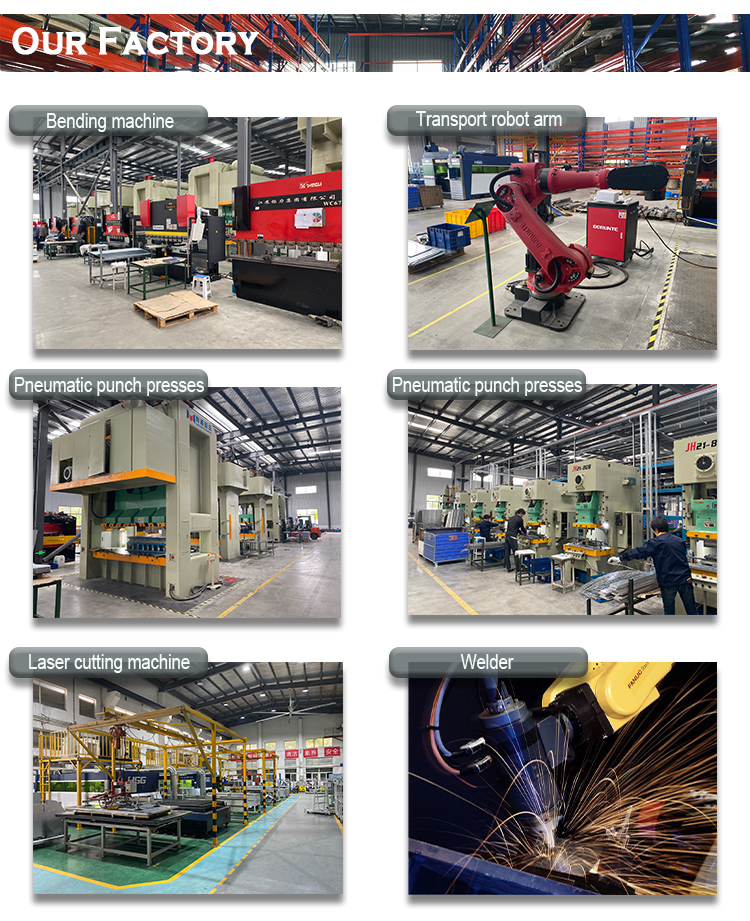

4 About Strong

Strong focused on metal manufacturing and has comprehensive ability in mold self-design, metal

stamping, sheet metal, laser cutting, powder coating, welding, plastic injection, etc.

Strong has many advanced production equipments: 50+ punch press machines (highest 1000 ton),

20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic

welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,

etc. In terms of the QC testing tool, We have CMM, a two-dimensional measuring instrument, hardness

tester, salty frog tester, etc.

5 FAQ

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance

before shipment.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: Are you a trading company or manufacturer?

A: We are a manufactory.

If you have another question, pls feel free to contact us.