Shanghai Strong Metal Production Co., Ltd. |

|

Verified Suppliers

|

|

Electrical automotive sheet metal stamping pliers parts manufacturing punching bending

1 About Powder Coating

Common manual repair technology of automobile sheet metal parts: use a variety of special tools to repair

parts that are not easy to enter, such as hammers, to repair some parts of tensile deformation by pressure,

and master the cold and hot method compared with the positive plate material and body correction, packing,

filling, and other processes. Repair of non-metallic components for some vehicles.

2 Technical Parameters

| Shape | needle/powder/granule/shot |

| Dimensions | Customzied, 50nm, -60, 100nm, |

| Color | Metal Silvery Gray, Grey, Black, silvery white of magnesium metal powder, dark .gray |

| Appearance | powder, Grey black powder, Yellow brownish |

| Purity | 99.9, 99%, or as you customized |

| Size | According to customer requirements, |

3 Product Details

Use: Car

Function: structure part of the car body, bracket

Technology: metal stamping, punch press, powder coating(black)

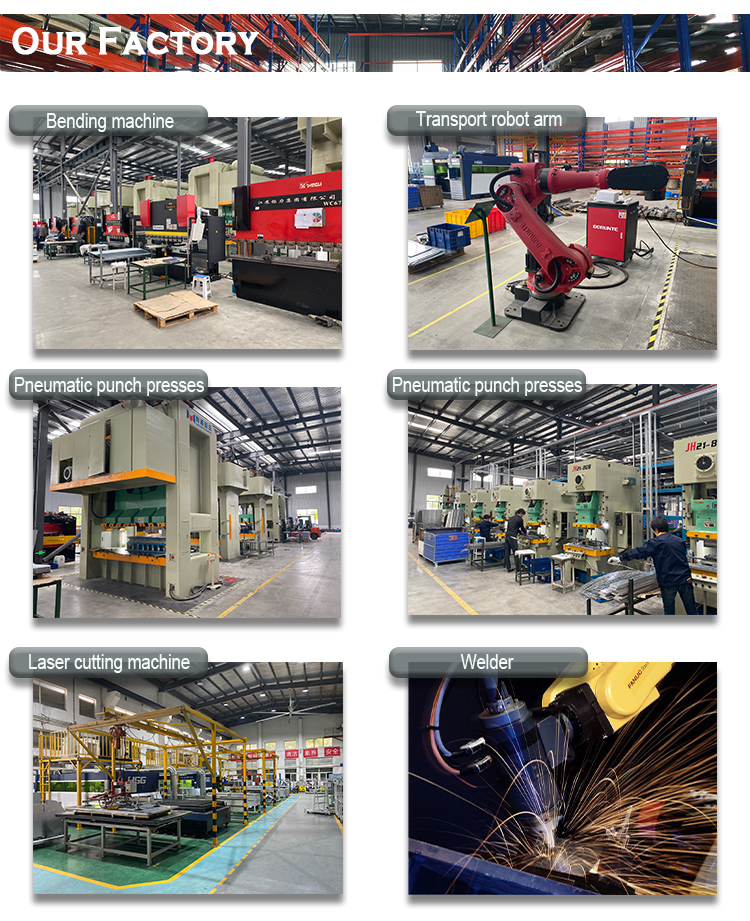

4 About Strong

Strong metal was established in June 2003 with a total registered capital of 67 million yuan and a total

construction area of 30,000 square meters. It has 5 factories in total which are located in Nantong,

Taicang, Nanjing, Vietnam, and Shanghai.

Strong has many advanced production equipments: 50+ punch press machines (highest 1000 ton),

20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic

welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,

etc. In terms of the QC testing tool,

5 FAQ

Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free but do not pay the

freight cost.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock,

it is according to quantity.

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance

before shipment.

If you have another question, pls feel free to contact us.