Riselaser Technology Co., Ltd |

|

Verified Suppliers

|

|

100w Pulsed Fiber Laser Handheld Laser Cleaning System

The laser with optical fiber output, fully closed and stable light path,over 100,000 hours continuous service life, lifelong maintenance-free, forced air cooling, machine integrated power 480W, environmental protection and energy saving, compact and portable.

Technical Parameters:

Characteristics | Test Condition | Min.value | Typical value | Max.value | Unit |

Operating Mode | Pulse | ||||

Polarization | Random | ||||

Laser Beam Mode | Customized for cleaning | ||||

Output Power | 100% output power | 99.9 | 100 | 110 | W |

Power Tunable Range |

| 50% |

| 100% |

|

Central Wavelength | 100% output power | 1060 | 1064 | 1068 | nm |

Pulse Width | 100% output power | 80 | 100 | 160 | ns |

Long Time Power Stability | 100% output power |

| ±2 | ±5 | % |

Total Consumption | 480W (AC110V or 220V) | ||||

Weight | 22.7KG | ||||

Cooling | Forced air | ||||

The problems of Traditional cleaning industry:

Mechanical FrictionCleaning high cleanliness, damage base material | Chemical Etching Cleaning unstressed cleaning, heavier pollution | Fluid solid jet cleaning high flexibility, high cost complex effluent treatment | High frequency ultrasonic cleaning good cleaning effect,limited size,dry workpeic |

Features of laser cleaning:

Laser cleaning——New technology,green and environmental:

Advantage:

Long-focus cleaning laser source has high surface roughness and high tolerance range of processing height on the workpiece, not only can be used in a stable industrial enviroment, more suitable for complex ourdoor fine cleaning; the use of special mode laser, both to ensure the high tolerance range of non-stable environment, but also efficient removal of rust stains with no hurt to base material.

Laser cleaning principle:

Fully enclosed external optical path system, combined with special mode of laser, the high-energy pulse laser collected in the surface of object,with the principles of plasma blasting,high energy pulse excitation and complex photochemical reactions, and by controlling the effective displacement of the laser beam to achieve cleaning. The whole process is controlled by the computer according to the program.

Application:

Mould Cleaning

| Peeling or Coat Removing

| Pretreatment before coating

| Airospace parts cleaning

|

| Soldering Welding Pretreatment

| Clean oxide,smeary,oil stain,residue

| Restoration and preservation

|

Typical Application - Rust Removal:

High energy pulsed laser focusing on the surface of object to simulate plasma, continuous irradiation of high-energy plasma instantaneous formation and expansion, resulting in a series of tiny explosions, formating plasma blasting, finally achieve the relativel smooth corrosive layer of boject surface to physical blasting burst, and move through the high speed laser spot to form a plume that will clean the debris to complete the cleaning. Mainly used in metal rust. |  |

Base material | Corroded degree (mm) | Cleaning effeciency (mm²/s) | Valid focal depth (mm) | Cleaning effect | Base matel damage |

Rusty carbon steel cast iron | medium corrosion 0.05mm | 4000 | >45 | good | no |

Typical Application——Degrease:

| High energy pulsed laser socusing on the surface of object,dirty rust and other irregular structure and dark surface absorpt the laser energy and plasma energy formated by metal surface, is instantaneous vaporization from the base metal. Mainly used in the mold cleaning and cultural relics repair and other industries. |  |

Base material | Corroded degree (mm) | Cleaning effeciency (mm²/s) | Valid focal depth (mm) | Cleaning effect | Base matel damage |

Greasy carbon steel

| medium oil pollusion mild rusty | 35000 | >60 | good | no |

Typical Application——Paint Removal:

For the paint and the surface of the chemical coating and special process, based on the surface and the base material has different absorption and damage threshold on laser, laser destruct the surface coating after focusing, after air contact, there are a series of complex photochemical reactions, oxidation, The final reaction product is in the form of gas discharge, the special mode of the laser below the masterbatch damage threshold, can peel off the coating, do not hurt the base material. Mainly used for paint removal and coating stripping. |  |

Base material | Corroded thickness (mm) | Cleaning effeciency (mm²/s) | Valid focal depth (mm) | Cleaning effect | Base matel damage |

white metal painting | >0.1 | 1500 | >30 | good | no |

Laser cleaning-working parameters:

| Base metal | Surface | Valid focal depth | Effeciency(mm²/s) | Effect |

| cast iron | severe corrosion(0.08mm) | >40 | 3000 | clean surface, no damage |

| carbon steel | mild corrosion(0.05mm) | >45 | 4000 | clean surface, no damage |

| stainless steel | oily, slight corrosion | >60 | 30000 | bright surface, no damage |

| mould steel gear | mild oily with scrap iron | >45 | 5000 | bright surface, no damage |

| aluminum steel | oxide/ surface spotting | >40 | 3000 | white surface, no damage |

| stoving varnish ss | white stoving varnish | >30 | 1000 | bright surface, no damage |

Core Laser Comparision:

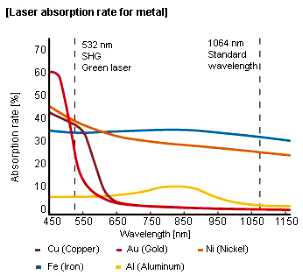

Based on the metal surface cleaning customized laser, according to the laser absorption rate of different wavelength of materias, the prior art selection of 1064 nm solid-state lasers or fiber lasers, metal absorption rate of up to 30%, with special mode spot, both can effectively clean rusty, and also protect Base metal with no damage. Considering the stability of laser, the use of cost and integration methods and other factors, the latest technology using wavelength of 1064nm fiber laser is better than solid lasers, Maxphotoncis 100W pulse laser cleaning source, is the best configuration for hand-held laser cleaning. |  |

| Laser Cleaning Source: | Advantage | Disadvantage |

| Solid Laser | 1.High power, high pulse energy, high cleaning efficiency 2.Wide range non-metallic material application 3.Excellent cleaning effect, excellent cleaning ability | 1. Large consumption, need high power chiller 2. Limited integration, complicated maintenance 3. Expensive and high cost. |

| Fiber Laser | 1.Free maintenance, high cost effective, low cost. 2.Forced air cooling, high stability of continuous using 3.Good laser beam mode, wide range metal application 4.Without light path problem, Flexibility integration, small and convenient 5.High photoelectric conversion rate, low consumption, energy saving and enviroment protection | 1.Low effective for thick coated metal 2.Power limited |