ZHANGJIAGANG CITY PEONY MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

Description

When developing the range of PDC series three-phase decanters for processing crude palm oil Peony focused on efficient, reliable separation of liquid, dry solids (cake) and oil for maximum oil recovery with minimum oil losses. The PDC range includes decanters suitable for every size of oil mill, from 30 to approximately 90 tons of fresh fruit bunches (FFB) per hour, and for a variety of crude palm oil applications including:

• Combined clarification and purification of pressed oil as part of the Peony all-in-one process (no need for settling tanks and dilution water), providing high oil recovery with low water consumption and effluent level.

• Sludge treatment after separation of diluted palm oil in settling

tanks, using the three-phase decanter as an alternative to a nozzle

separator. The decanter efficiently separates the slurry into oil,

water and solid cake phases.

• Oil recovery from empty fruit bunch liquor (EFBL) immediately

after pressing. After separation and removal of impurities with a

decenter, the recovered high quality palm oil can be mixed with the

freshly pressed oil.

Application

Peony Decanter Centrifuge Systems machines can: Remove particles as small as 2 microns,separating bean seed oil,sunflower oil,fish oil,fish meat,sobean protein ,peanut protein,juice,beverage.waste oil purification,washing water purification,orange juice,benzonic acid ,coconut milk,edible oil,palm oil,olive oil,etc.

Materials

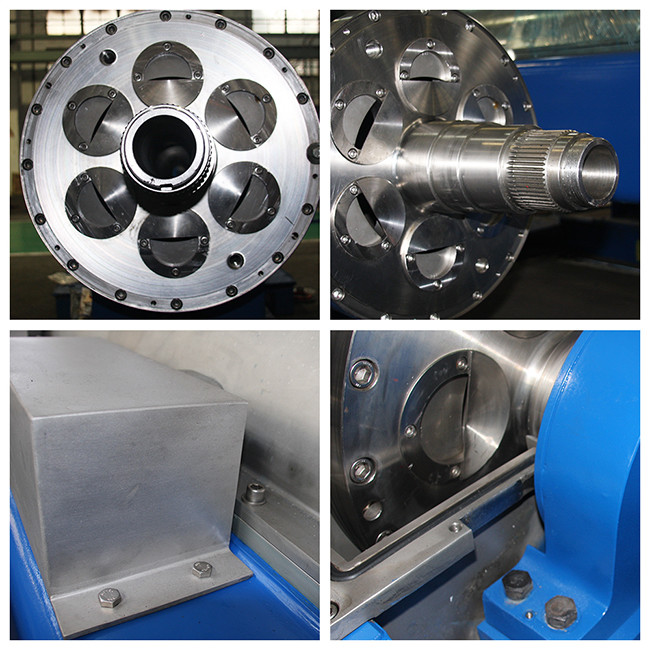

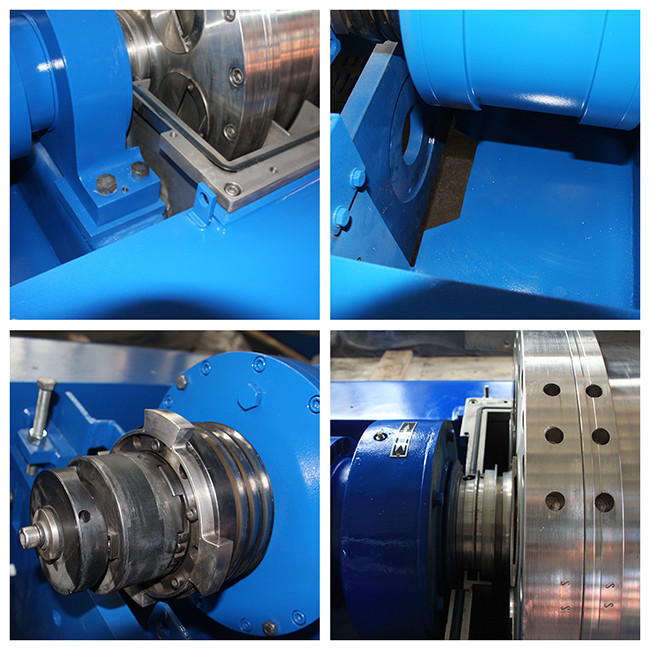

Main parts (e.g the bowl and conveyor) are made of corrosion-resistant stainless steel

Gear box of planetary differential and cycloidal needle wheel structure both available for choose,with import brand hydraulic gear box .Screw conveyor flights tiled or lined with ceramic, tungsten carbide, or other hard alloys.for vegetable oil and animal oil,commonly,TC sprayed is more economical and more suitable.

Safety protection

Bowl speed and differential speed detection, over-vibration protection,overload and overheat protection, bearing temperature monitoring, conveyor torque protection and gas-tight explosion-proof protection.

Specifications

Model | Drum | G-force | Capacity (m3/h) | Power (kw) | |||

Diameter (mm) | Speed (rpm) | Length (mm) | Length-to-diameter rate | ||||

PDC-10-W | 250 | 5400 | 1000 | 4 | 4080 | 0.5~5 | 7.5/3 |

PDC-12-4-W | 300 | 4200 | 1200 | 4 | 3500 | 1~5 | 11/4 |

PDC-12-4.5-W | 300 | 4200 | 1350 | 4.5 | 3000 | 1~10 | 11/4 |

PDC-14-W | 355 | 4000 | 1600 | 4.5 | 3180 | 1~20 | 18.5/7.5 |

PDC-16-W | 400 | 3650 | 1800 | 4.5 | 3000 | 2~25 | 22/7.5 |

PDC-18-4.4-W | 450 | 3200 | 2000 | 4.4 | 2600 | 3~35 | 30/11 |

PDC-18-4.8-W | 450 | 3200 | 2150 | 4.8 | 2600 | 4~40 | 37/11 |

PDC-20-4-W | 500 | 3000 | 2000 | 4 | 2500 | 5~45 | 37/11 |

PDC-20-4.5-W | 500 | 3000 | 2250 | 4.5 | 2500 | 8~50 | 45/15 |

PDC-21-W | 530 | 2900 | 2280 | 4.3 | 2500 | 15~65 | 55/15 |

PDC-23-W | 580 | 2780 | 2500 | 4.3 | 2500 | 20~80 | 75/18.5 |

PDC-26-W | 650 | 2500 | 2800 | 4.3 | 2270 | 25~110 | 75/18.5 |

Separation principle

In the gravity force field or centrifugal force field, the liquid phase and the solid phase with different density and mutually insoluble in the mixed liquid, respectively gain different sedimentation speed, and thus separate and stratify. In the gravity force field it is called gravity separation, while in the centrifugal force field it is called centrifugal separation.

The machine could deal with the material which range of concentration is large, small size which widely distributing. Solid particles are less 0.5mm as rigid particles, and less than 10mm as non-rigid particles, the machine can be effectively treated.The decanter centrifuge is applicable to the separating of suspension containing solid-phase granules with diameter greater than 0.005 mm and with the concentration being 2~40%.

Overview

Decanter Centrifuge for Palm Oil