Supanchor Rock Reinforcement Co., Ltd. |

|

Features

Basalt Rebar is an outstanding product for concrete reinforcement. It weighs 5 times less than steel rebar and its tensile strength is 3 times higher. Basalt rebars are manufactured from basalt fibers by pultrusion technology. Basalt rebar does not conduct electricity or induce fields when exposed to RF energy, great for MRI or data buildings. On average 60% less CO2 emission in final concrete structures due to production process, logistics and material optimization.

The surface is profiled and sanded. This kind of surface treatment results in a better adhesion in concrete.

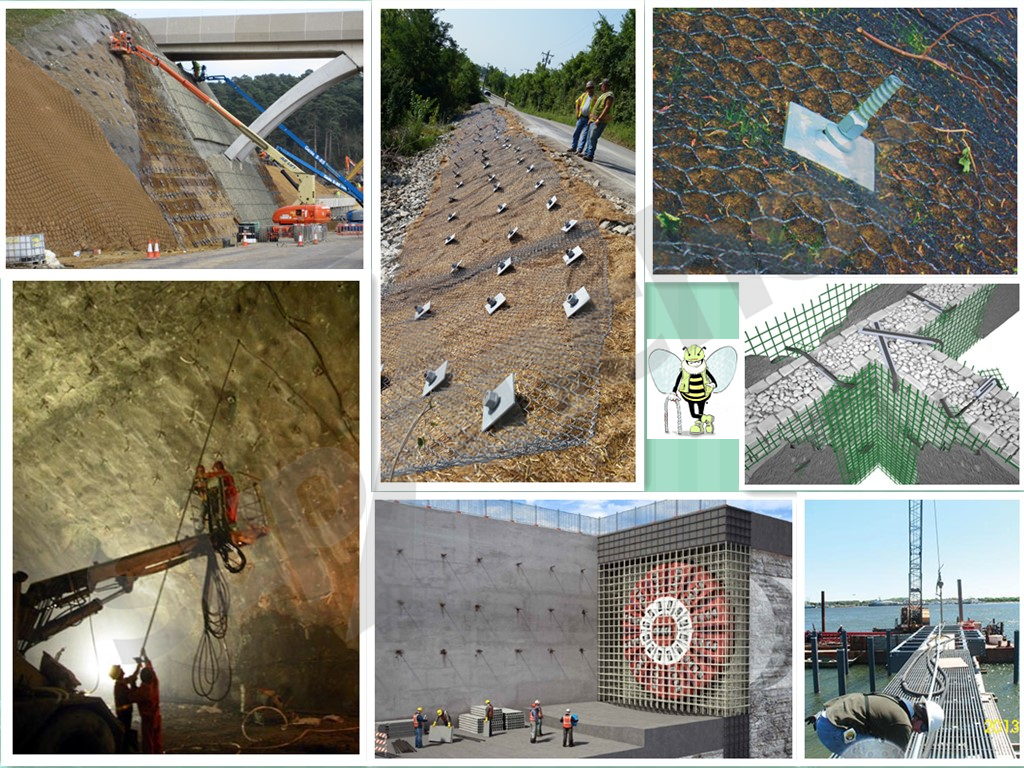

Applications

1. Industrial floors

2. Tunnels

3. Bridge decks

4. Concrete roads

5. Infrustructural elements

6. RF energy

Advantages

1. Elasticity

2. Chopped to the desired length

3. Resistant to a corrosive invironment

4. Saving concrete

5. Lightweight construction

6. No need to separation from concrete after lifecycle

7. Overall project cost is less than with steel rebar

Technical data

| BFRP Reinforcement Rebar | ReB-8 | ReB-10 | ReB-12 | ReB-14 | ReB-16 | ReB-18 |

| Outside Diameter (mm)*1 | 9 | 11.5 | 14 | 16 | 18 | 20.5 |

| Guaranteed tensile load (kN) | 75 | 119 | 170 | 231 | 302 | 381 |

Nominal Cross sectional area (mm2)*2 | 50 | 79 | 113 | 154 | 201 | 254 |

| Tensile Strength (Mpa) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Ultimate Strain | 2.5% | |||||

| Tensile E-Modulus (GPa) | 62 | |||||

| Weight (kg/m) | 0.125 | 0.20 | 0.28 | 0.38 | 0.50 | 0.65 |

* 1 Including Waved Thread Structure

* 2 Characteristic Stress Value in core

Application

SubNumbers

10 Years - The average seniority > 10 years, which is not common in anchor manufacturing industry.

20 Years - 20 years of exporting experience, familiar with different product standards from different

customers and countries.

26 Years - 26 years of exploration and development, SupAnchor has become the No.1 SDA bar

manufacturer in Asia.

60 Countries - customers from 60 countries. Our self drilling anchor systems have been used by

customers from 50 countries all over the world, including America, Chile, Germany,