Shanghai Xunhui Environment Technology Co., Ltd. |

|

Flat sheet PVDF membrane bio-reactor MBR for sewage & waste water treatment plant 20m3/day

MBR introduction

The membrane bio reactor / MBR is the latest technology to treat municipal sewage as well as vairous industrial wastewater from around the world. Our FS MBR modular for MBR systems, are made of PVDF, removes suspended solids (SS) and microorganisms, such cryptosporidium, Escherichia coli from the sludge liquid, it's more effectively then the traditional sedimentation process, offers you extraordinarily high effluent quality.

Specifications

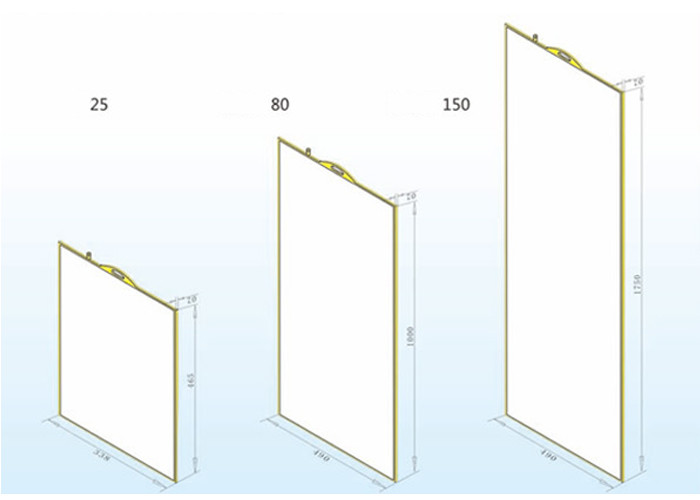

| Model of FS | 150 | 80 | 25 | 10 |

| Effective membrane area (m2) | 1.5 | 0.8 | 0.25 | 0.1 |

| Size L*W*T (mm) | 490*1750*7 | 490*1000*7 | 340*470*7 | 220*320*6 |

| Weight (kg) | 5.5 | 3.2 | 0.8 | 0.4 |

| Pore size (µm) | <0.10 | |||

| Membrane material | PVDF | |||

| Flux (L/pc.day) | 600 - 800 | 320 - 480 | 100 - 150 | 40 - 60 |

| Aeration capacity (L/pc.min) | >12 | >12 | >9 | >6 |

| PH range | 3 - 12 | |||

| Outlet effluent turbidity (NTU) | <0.1 | |||

| Outlet effluent SS (mg/L) | <5 | |||

Above datas are tested at standard single sheet FS MBR with municipal waste water at 25 ℃ and operation pressure 10Kpa.

Key features

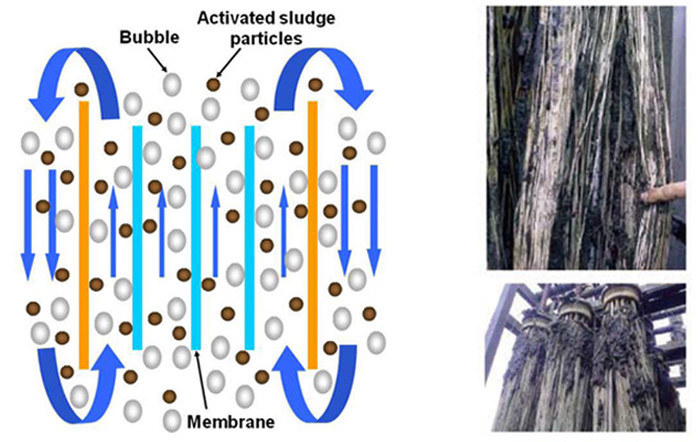

1. High fouling resistance

Numerous small-diameter pores are distributed evenly throughout the

membrane surface with a narrow diameter distribution. This

structure results in higher treated water quality, minimizes

membrane fouling and pore clogging and delivers high water

permeability.

2. High water permeability and high effluent quality

3. Physical strength and chemical stability

Using PVDF (polyvinylidene fluoride) for the func t iona l l a yer

of the membrane and PET (polyester) non-woven fabric as the base

layer allows the membrane to exhibit super ior phy s i cal s t

rength and

chemical stability.

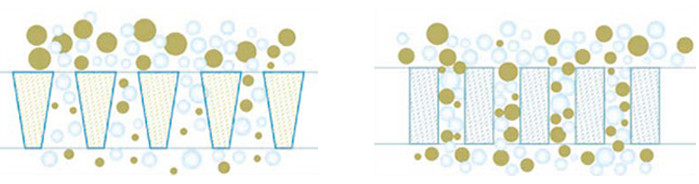

Asymmetric structure for fouling resistance

Asymmetric structure Symmetric structure

Comparison between flat sheet membrane and hollow fiber membrane

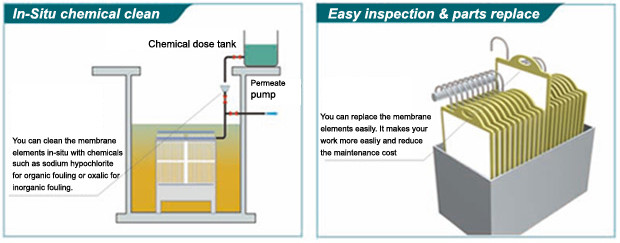

Easily clean and membrane replacement

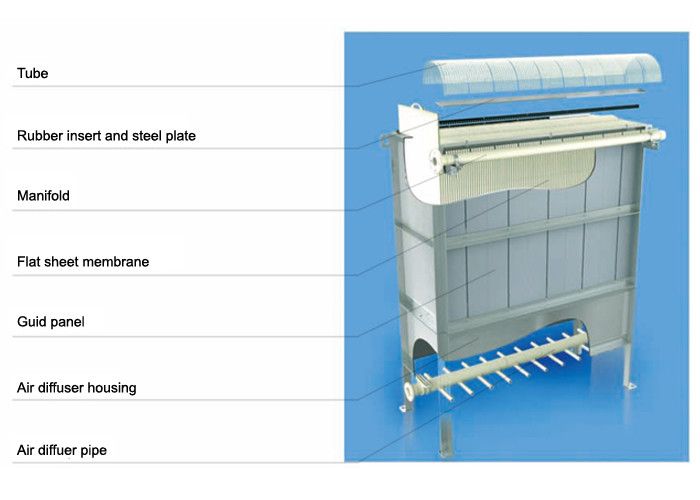

Specifications of modular

<

| Model | MBR element | Nos of MBR | Membrane area | Capacity | Max capacity | net weight | Air supply |

| (piece) | (m2) | (m3/day) | (m3/day) | (kg) | (L/min) | ||

| 80-50 | S80 | 50 | 40 | 20 | 40 | 340 | 600 |

| 80-60 | 60 | 48 | 24 | 48 | 380 | 720 | |

| 80-80 | 80 | 64 | 32 | 64 | 470 | 960 | |

| 80-100 | 100 | 80 | 40 | 80 | 560 | 1200 | |

| 80-120 | 120 | 96 | 48 | 96 | 660 | 1440 | |

| 80-140 | 140 | 112 | 56 | 112 | 770 | 1680 | |

| 80-150 | 150 | 120 | 60 | 120 | 830 | 1800 | |

| 80-160 | 160 | 128 | 64 | 128 | 900 | 1920 | |

| 80-200 | 200 | 160 | 80 | 160 | 1140 | 2400 | |

| 150-50 | S150 | 50 | 75 | 37.5 | 75 | 420 | 600 |

| 150-60 | 60 | 90 | 45 | 90 | 520 | 720 | |

| 150-80 | 80 | 120 | 60 | 120 | 670 | 960 | |

| 150-100 | 100 | 150 | 75 | 150 | 730 | 1200 | |

| 150-120 | 120 | 180 | 90 | 180 | 890 | 1440 | |

| 150-140 | 140 | 210 | 105 | 210 | 1050 | 1680 | |

| 150-150 | 150 | 225 | 112.5 | 225 | 1140 | 1800 | |

| 150-160 | 160 | 240 | 120 | 240 | 1230 | 1920 | |

| 150-200 | 200 | 300 | 150 | 300 | 1550 | 2400 |

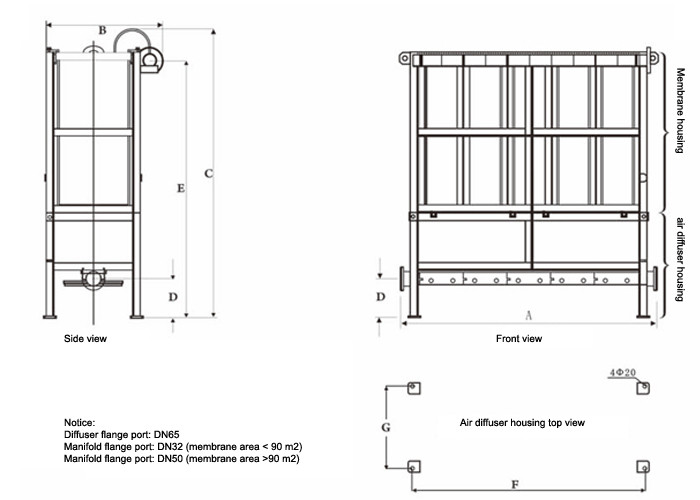

Dimensions

| Model | MBR element | Membrane area (m2) | Capacity (m3/day) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) |

| 80-50 | S80 | 40 | 16 - 24 | 965 | 720 | 1850 | 240 | 1695 |

| 80-60 | 48 | 19 - 28 | 1090 | |||||

| 80-80 | 64 | 25 - 38 | 1385 | |||||

| 80-100 | 80 | 32 - 48 | 1670 | 755 | 1693 | |||

| 80-120 | 96 | 38 - 57 | 1950 | |||||

| 80-140 | 112 | 44 - 67 | 2230 | |||||

| 80-150 | 120 | 48 - 72 | 2375 | |||||

| 80-160 | 128 | 51 - 76 | 2530 | |||||

| 80-200 | 160 | 64 - 96 | 3100 | |||||

| 150-50 | S150 | 75 | 30 - 45 | 965 | 720 | 2600 | 240 | 2445 |

| 150-60 | 90 | 36 - 54 | 1090 | |||||

| 150-80 | 120 | 48 - 72 | 1385 | 755 | 2443 | |||

| 150-100 | 150 | 60 - 90 | 1670 | |||||

| 150-120 | 180 | 72 - 108 | 1950 | |||||

| 150-140 | 210 | 84 - 126 | 2230 | |||||

| 150-150 | 225 | 90 - 135 | 2375 | |||||

| 150-160 | 240 | 96 - 144 | 2530 | |||||

| 150-200 | 300 | 120 - 180 | 3100 |

Applications

Emulsified oil waste water Hospital waste water Scenic spot sewage

landfill leachate wafter grinding waste water woolen waste water

dairy, food & beverage pharmaceutical heat sanitizable

whey plants concentration WPI plants Gelatine

Sugar