Shanghai Xunhui Environment Technology Co., Ltd. |

|

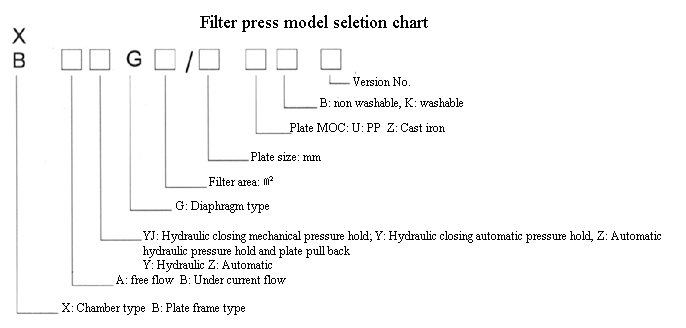

Polypropylene high pressure plate and frame filter press for sludge dehydrator membrane type

The membrane plate and frame filter press, is with automatic

plate pulling out device by mechanical arm. It saves labor cost.

It's feed from one corner, which are widely used in waste water or slurry treatment, industries from plating and metal finishing to chemical and food processing. Our filter Presses feature heavy duty steel construction with polypropene gasketed plates. These filter presses can be manufactured with manual or automatic closures, but always with a hydraulic cylinder for sure, high pressure closing. The filter pressescan be expanded for larger future capacity by building it in a larger skeleton with a distance piece. Once you are ready to expand, you can remove the distance piece and add the extra plates.

Work process

The diaphragm filter press comprises a set of vertical, juxtaposed

recessed plates, presses against each other by hydraulic jacks at

one end of the set. The pressure applied to the joint face of each

filtering plate must withstand the chamber internal pressure

developed by the sludge pumping system.

This vertical plate layout forms watertight filtration chambers

allowing easy mechanisation for the discharge of cakes.

Filter chlotes finely or tightly meshed are applied to the two groowed surfaces in these plates. Orifices feed the sludge to befiltered under pressure in the filtration chamber. They are usually placed in the center of the plates allowing a proper distribution of flow right pressureand better drainage of sludge within the chamber.Solid sludge gradually accumulate in the filtration chamber until the final compacted cake is formed. The filtrate is collected at the back of the filtration support and carried away by internal ducts.

Filtration cycle

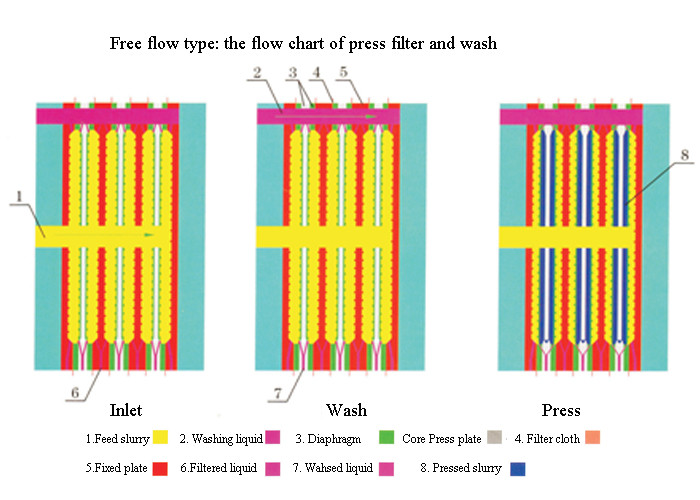

Flow chart of squeezing press filtering and washing - Free flow type

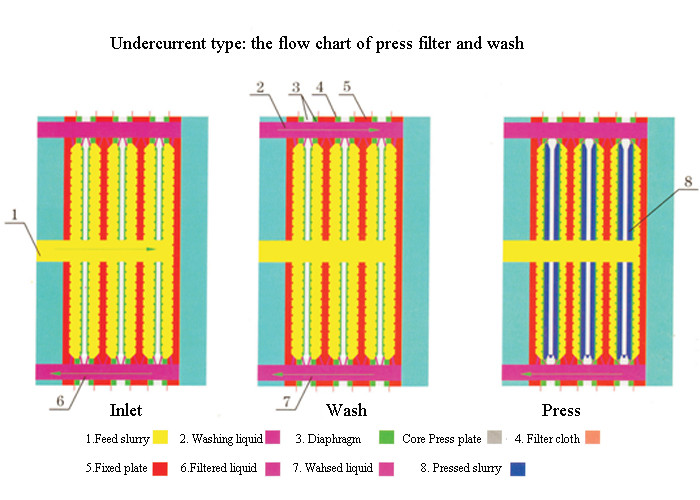

Flow chart of filtering, washing and crushing flow chart - Under current flow type

Filtration capacity

The production capacity of a filter press is somewhere between 1.5 and 10 kg of solid per m2 of filtering surface.

For

every the filter press model the chamber volume and the filtering surface depend on the number of plates in the

filer.

In practical terms pressing times are less then four hours.

Filtration time depends on:

One of the advantages of the filer press is that it can accept sludge with average filterability. It is always advantageous to

optimally thicken sludge before filter press operations. Although sludge presenting a high filterability enables better production

capacities, a filter press still accepts sludge with low conditioning precision. This tolerance means that the device offers

greater owerall operational safety.

Data sheet

| Model | Filter area (㎡) | Volume of filter chamber | Thickness of plate /frame (mm) | Pressure in filter chamber (Mpa) | Work temperature ℃ | Nos of filter plate/frame | Motor power | Dimensions (mm) | GW (kg) |

| XAYG800-1 | 10 | 150 | 65/60 | <0.8 | <70 | 5/4 | 4 | 2620x1150x1200 | 2200 |

| XAYG800-2 | 20 | 300 | 65/60 | <0.8 | <70 | 10/9 | 4 | 3255x1150*1200 | 2550 |

| XAYG800-3 | 30 | 450 | 65/60 | <0.8 | <70 | 15/14 | 4 | 3890x1150*1200 | 2920 |

| XAYG800-4 | 40 | 600 | 65/60 | <0.8 | <70 | 20/19 | 4 | 4525x1150*1200 | 3300 |

| XAYG800-5 | 50 | 750 | 65/60 | <0.8 | <70 | 25/24 | 4 | 5160x1150*1200 | 3900 |

| XAYG800-6 | 60 | 900 | 65/60 | <0.8 | <70 | 30/29 | 4 | 5795x1150*1200 | 4350 |

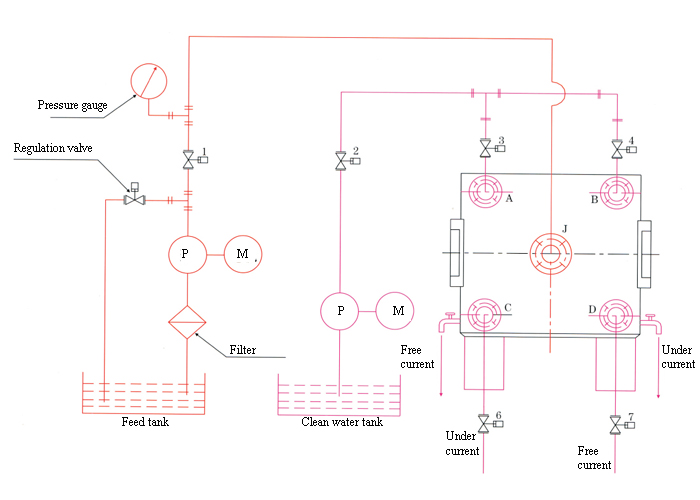

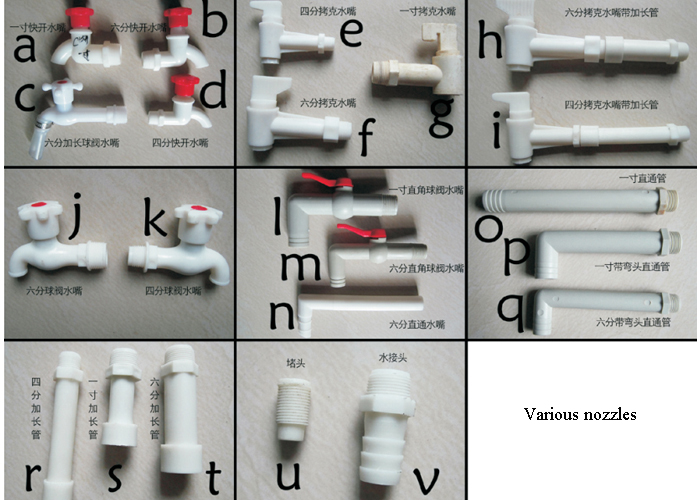

Pipe line diagraphm

Pipe line diagraphm

Performance

The filter press is suitable for almost all types of sludge:

Hydrophilic organic sludge: inorganic

conditioning is often recommended to enable satisfactory cake

release due to minimal

aderence to filter cloth.

Hydrophilic inorganic sludge: the filer press

generally requires the addition of lime only.

Hydrophobic inorganic sludge: it is very dense

and ideal for the filter press. It is dewatered without any

preliminary conditioning.

Oily sludge: the filter press can be used to

treat sludge containing light oils, the presence of grease can

sometimes impair the

smooth running of the filter; clothes have to be

degreased at frequent intervals.

Accessories

Competitive advantage

Quality - Rapid filtration, highly automated, stable performance, easy

operation and equipped high temperature, high pressure,

anti-corrosion, reliably sealing filter plates. We strictly execute

ISO9001 quality control system, striving to offer our client the

products with advanced technology and best quality to achieve the

best filtration.

Service We always have the faith that customer is highest. Before selling

out products, we offering technology advice, solution design and

give guidance on installation and commissioning. We always follow

the using status of our machine, striving to offer all-round

premium service.

Technology We constantly adopt advanced technology for filter press to make

the products apply with the most innovative science &

technology. We also can make custom designed filter press, filter

plates and accessories. To meet the market demand, we brought novel

& leading technology filter presses together with German

designers.