TORICH INTERNATIONAL LIMITED |

|

Verified Suppliers

|

|

Aluminum CNC Machining 45# CNC Turning Milling CNC Machining Parts Clamp

1.Quick detail:

| Name | Cnc Turning Milling Machining Parts,Aluminum Cnc Machining |

| Material | 45# |

| Surface | Degreasing, polishing, deburring,etc |

| Application | Auto parts, power industry, bridge construction,bearing,etc |

| Testing equipment | Automatic height gauge;multi-joint arm; Marble platform; Roughness measurement; etc |

| Tolerance | +/-0.01mm, 100% QC inspection |

| Package | PE plastic bag, Paper fiber, carton, wooden pallet, or as required |

| Surface treatment | Nickel-plated, zinc-plated, silver-plated, gold-plated, oxidized,Sand blasting, Brushing & polishing of cnc mechanical parts. |

| Process | Knurling, thread rolling, punching, tapping, cylindrical grinding, wire cutting |

What is Aluminum CNC machining

Aluminum CNC machining is a process of removing material from a block of aluminum to create a desired shape or design using a computer numerical control (CNC) machine. This process involves the use of precision cutting tools, which are controlled by a computer program to accurately cut and shape the aluminum material.

One of the key benefits of aluminum CNC machining is its high level of precision and accuracy. The computer program used to control the cutting tools ensures that the aluminum material is cut exactly as intended, resulting in a finished product that meets the exact specifications of the design.

Another benefit of aluminum CNC machining is its versatility. The process can be used to create a wide range of shapes and designs, from simple geometric shapes to complex 3D designs. This makes it an ideal choice for a variety of applications, including aerospace, automotive, and medical industries.

In addition to its precision and versatility, aluminum CNC machining also offers a number of other advantages. For example, the process is relatively fast and efficient, allowing for large quantities of parts to be produced quickly and cost-effectively. It also produces minimal waste, as the excess material can often be recycled or reused.

Overall, aluminum CNC machining is a highly effective and efficient process for creating precision parts and components from aluminum material. Its versatility, precision, and efficiency make it an ideal choice for a wide range of applications across various industries.

2.About Cnc Turning Milling Machining Parts:

CNC turning milling machining parts refer to components that are manufactured using a CNC (Computer Numerical Control) machine that has both turning and milling capabilities. These machines are used to create complex and precise parts that may be difficult or impossible to produce using traditional manufacturing methods.

CNC turning involves rotating the workpiece while a cutting tool removes material to create the desired shape. CNC milling, on the other hand, uses a rotating cutting tool to remove material from a stationary workpiece. By combining these two processes, CNC turning milling machines can create parts with intricate shapes and precise dimensions.

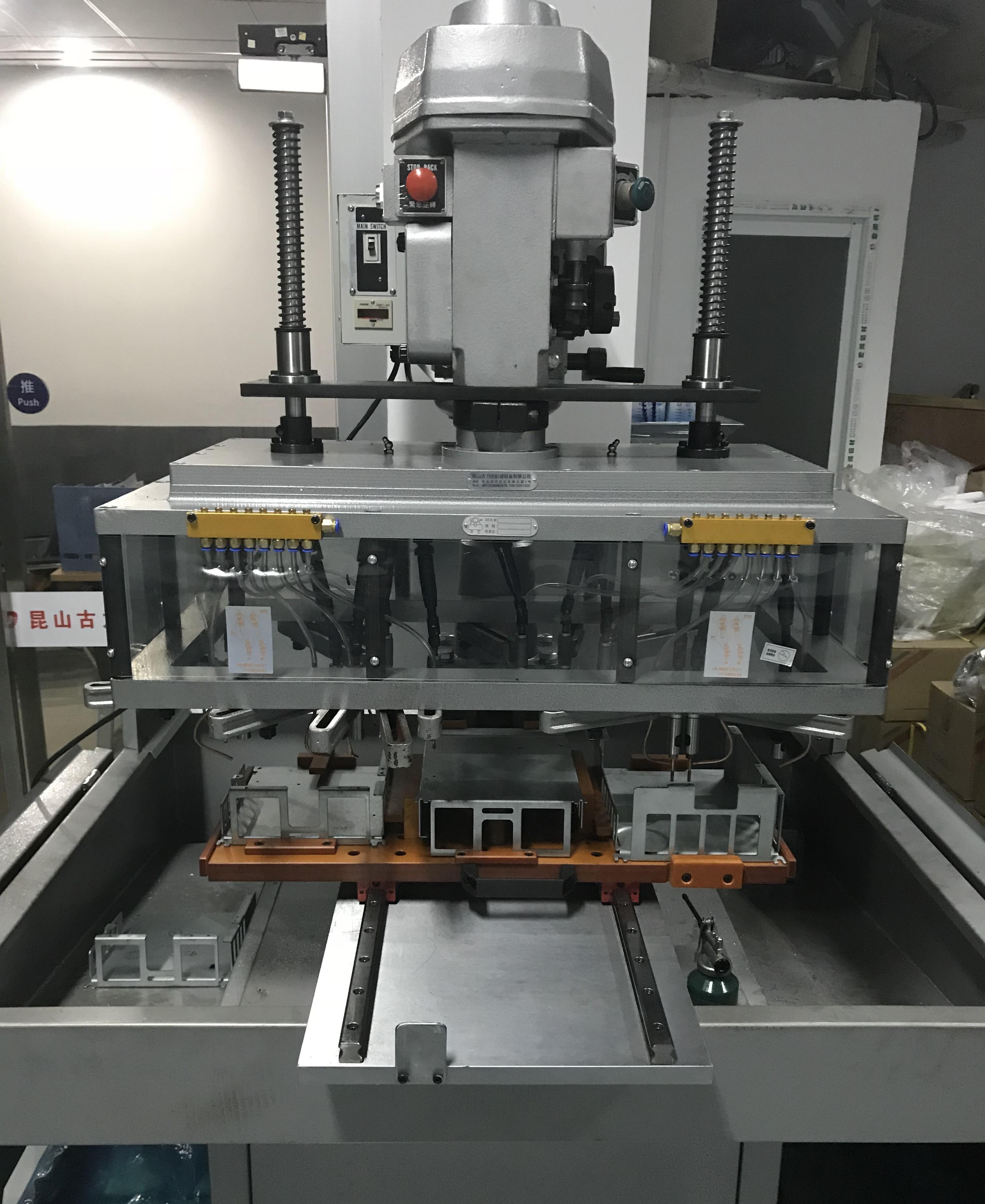

4.Picture from our production:

5.Production facility:

TORICH offers Aluminum Cnc Machining service, based on the metal material like carbon, alloy, copper, stainless, etc. We foucus on the metal & plastic rapid prototyping and CNC machining services with low volume. TORICH has had ISO 9001 certification.

What we have: 3-axis, 4-axis and 5-axis CNC machines, Radial Drilling Machine, Automatic lathe walking machine, Cnc Machine Laser etc.

6.FAQ

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is

30-60 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples of CNC machining accessories ? is it free

or extra ?

A: Yes, we could offer the sample for free charge but need pay the

cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

Q:How to get the sample of CNC ?

A:1. You are requested to pay for sample charges and courier

charges from China to your country; and the free sample is

according the product like size, steel grade and quantity, please

consult our sales for details

2. Sample charges will be refunded when order is placed.