CEBE GROUP HK CO.,LTD |

|

Verified Suppliers

|

|

GA 30+-90 Premium Compressor

• High performance Free Air Delivery.

• Premium quality at the lowest initial investment.

• Integrated refrigerant dryer.

• Standard Elektronikon ® controller (optional Touch controller).

(A)

Integrated highly efficient R410A dryer

• Excellence in air quality.

• 50% reduction in energy consumption compared to traditional

dryers.

• Zero ozone depletion.

• Incorporates optional UD + filter according to Class 1.4.2.

(B)

NEOS drive

• Atlas ’s in-house designed inverter for GA VSD compressors.

• IP5X protection degree.

• A robust, aluminum enclosure for trouble-free operation in the

harshest conditions.

• Fewer components: compact, simple and user-friendly.

(C)

Cubicle cooling booster

• Cubicle in overpressure minimizes ingress of conductive dust.

• Electrical components remain cool, enhancing lifetime of

components.

(D)

Elektronikon ® for remote monitoring

• Integrated smart algorithms reduce system pressure and energy

consumption.

• Monitoring features include warning indications, maintenance

scheduling and online visualization of machine’s condition.

(E)

Heavy-duty air intake filter

• Protects the compressor components by removing 99.9% of dirt

particles down to 3 microns.

• Differential inlet pressure for proactive maintenance while

minimizing pressure drop.

Advanced Elektronikon ® Touch controller

• Improved user-friendliness: 4.3-inch high-definition color

display with clear pictograms and service indicator.

• Internet-based compressor visualization using a simple Ethernet

connection.

• Increased reliability: new, user-friendly, multilingual user

interface.

Key features:

• Automatic restart after voltage failure.

• Built-in SMARTLINK online monitoring.

• Dual pressure set point.

• More flexibility: four different week schedules that can be

programmed for a period of 10 consecutive weeks.

• On-screen Delayed Second Stop function and VSD savings

indication.

• Graphical service plan indication.

• Remote control and connectivity functions.

• Software upgrade available to control up to 6 compressors by

installing the optional integrated compressor controller.

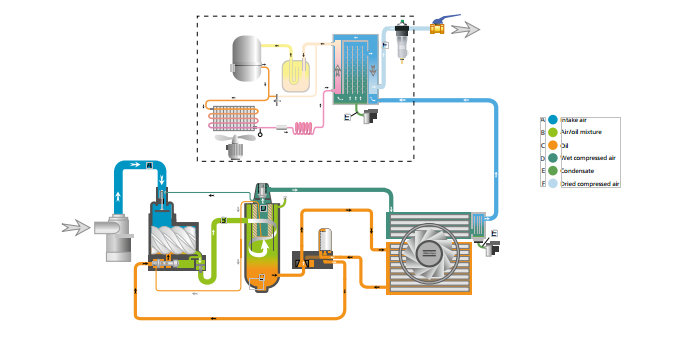

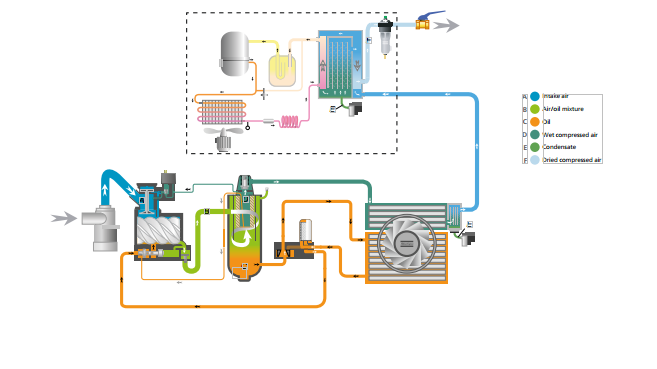

Flow charts

Variable Speed Drive: GA VSD

Fixed speed: GA+ & GA

The ultimate smart solution, driven by efficiency

Atlas ’s GA 30+-90 compressors bring you outstanding

sustainability, reliability and performance, while minimizing the

total cost of ownership. A choice of three premium compressor types

(GA VSD, GA+ and GA) provides you with the compressed air solution

that perfectly matches your requirements with clear value

propositions. Built to perform even in the harshest environments,

these compressors keep your productionrunning efficiently.

1,Maintenance-free drive system

• 100% maintenance-free; totally enclosed and protected against

dirt and dust.

• Suitable for harsh environments.

• High-efficiency drive arrangement; no coupling or slippage losses.

• Standard up to 46°C/115°F and for high ambient version

55°C/131°F.

2,IE3 Premium Efficiency electrical motors

• IP55, insulation Class F, B rise.

• Non-drive side bearing greased for life.

• Oil lubricated drive side bearings.

3,Robust spin-on oil filter

• High-efficiency, removing 300% smaller

particles than a conventional filter.

• Integrated bypass valve with the oil filter.

4,Separate oversized oil cooler and aftercooler

• Low element outlet temperatures, ensuring long oil lifetime:•

Removal of nearly 100% condensate by mechanical separator.

• No consumables.

• Eliminates possibility of thermal shocks in coolers.

5,Advanced control & monitoring via Elektronikon®

• Integrated smart algorithms reduce system pressure and energy

consumption.

• Monitoring features include warning indications,maintenance

scheduling and online visualization of machine’s condition.

6,Heavy-duty air intake filter

• Protects the compressor components by removing 99.9% of dirt

particles down to 3 microns.

• Differential inlet pressure for proactive maintenance while

minimizing pressure drop.

7,Electronic no-loss water drain(optional)

• Ensures constant removal of condensate.

• Manual integrated bypass for effective condensate removal in case

of power failure.

• Integrated with compressor’s Elektronikon® with warning/alarm

features.

8,Radial fan

• Low noise level. • High flows.

• Compact design.

9,Integrated highly efficient R410A dryer

• Excellence in air quality.

• 50% reduction in energy consumption compared to traditional

dryers.

• Zero ozone depletion.

• Incorporates optional UD+ filter according to Class 1.4.2.