Atlas Copco's tradition of driving industrial innovation has

allowed us to design the DWS VSD⁺ dry screw pump, an important

addition to our innovative range of industrial dry pumps.The DWS

VSD⁺ dry screw pump is an important addition to our range of

innovative industrial dry pumps.

The DWS VSD⁺ range features a smart, simple design that is durable

and delivers performance, utilising the concept of the concept of

simple control and reduce maintenance costs.

1.Higher operating performance and stable vacuum level

Increased productivity and shorter evacuation times due to higher

roughing speeds and lower ultimate pressures down to <10⁻².

2.Rugged design for harsh industrial applicationsThe DWS VSD⁺ series features a rugged design for extended

uptime.longer maintenance intervals,low maintenance costs.

3.Low running costsVariable Speed Drive (VSD) technology optimises energy consumption,

resulting in significant energy savings. In addition, the compact

design reduces the amount of space occupied in the production hall

or machine room.

4.Environmentally friendlyThe dry screw technology of the DWS VSD⁺ means that there are no

emissions of oily oil mist. It has a minimal impact on the

environment and reduces recurring maintenance costs.

Innovation from the heart, intelligence from the mind

Screw vacuum technology is the ideal solution for many applications

such as packaging, drying, electronics, plasma processes, LED

manufacturing and solar energy, to name just a few applications. It is clean, efficient and

offers a great deal of convenience.

1.Pre-wired and systemised

- Rugged, compact enclosure meets IP54 requirements

- Electrical connections connected, wired and assembled

- Plug and play, easy to install

2.Robust construction and cleverly designed components- Reliable constant flow cooling system

- Reliable new purge system including manual gas ballast

- Non-contact, long-life seals for efficient sealing

3.Intelligent Technology

- With Elektronikon® for advanced remote monitoring of the pump,

e.g. status, run/shutdown times,programmable timers and setpoint

control, etc.

- Gearbox and vacuum chamber are isolated from contamination and

remain oil-free from overflow

- State-of-the-art high quality bearings and low volatile

speciality lubricants

- The non-cantilevered design provides excellent rotor support,

ensuring fast start-up and low vibration.

- Pneumatic air inlet valves are included as standard equipment.

The air inlet valve is operated by the Mk5 computerised

controller.Automatic warm-up and shutdown purge cycles are

possible, with automatic isolation from the vacuum network.

Technical specification

| | | Metric | Inch |

| Performance | Peak pumping speed | m³h⁻¹ | 450 | CFM | 265 |

| Ultimate pressure | mbar | <0.01 | Torr | <0.008 |

| Full load motor power | At ultimate vacuum | KW | 6 | throttle | 8 |

| At maximum load | KW | 12 | throttle | 16 |

| Vacuum connection | Inlet connection | | ISO 100 | | ISO 100 |

| Exhaust connection | | NW50 | | NW50 |

| Cooling water | Connection | | G3/8"internal thread | | G1/2"internal thread |

| Flow rate | l·min⁻¹ | 10 | gal-min-1 | 2.6 |

| Supply pressure(max) | bar | 6.9 | psig | 100 |

| Pressure drop(min) | bar | 1 | psig | 14.5 |

| Temperature | ℃ | 5-40 | °F | 41-104 |

| Purging gas | Connection | | G1/2"internal thread | | G1/2"internal thread |

| Pressure | bar | 2.5-6.9 | psig | 43.5-100 |

| Purging gas flow rate | l·min⁻¹ | 12 | l·min⁻¹ | 12 |

| Gas ballast flow | l·min⁻¹ | 0-128 | l·min⁻¹ | 0-128 |

| Dperating parameters | Noise | dB(A) | <64 | dB(A) | <75 |

| Operating temperature | ℃ | 5-40 | °F | 41-104 |

| Exhaust back pressure (upper limit) | mbar | 1200 | psia | 17.4 |

| Lubricating grease (as supplied) | | PFPE Drynert 25/ 6 | | PFPE Drynert 25/ 6 |

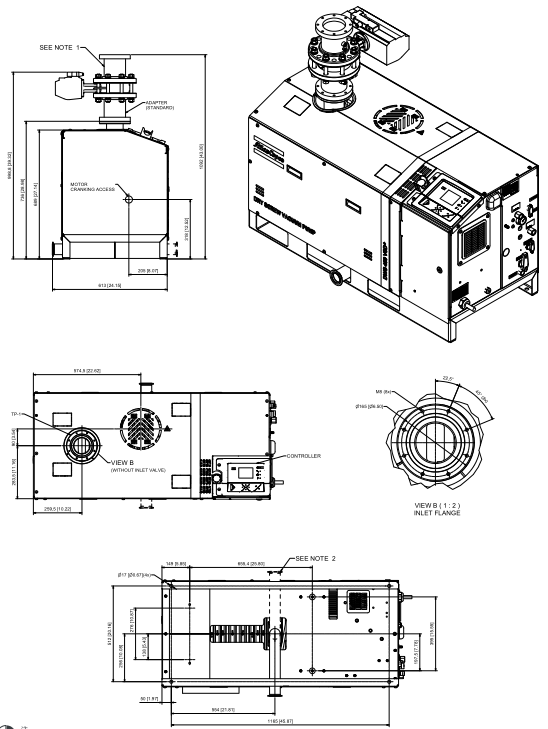

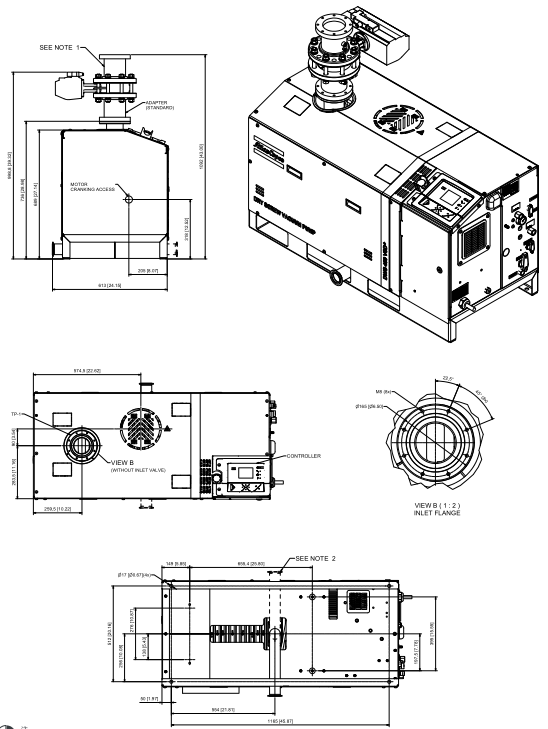

Dimensions