CEBE GROUP HK CO.,LTD |

|

Verified Suppliers

|

|

GHS 350-1900 VSD+ series

Oil-sealed rotary screw vacuum pumps with Variable Speed Drive

(VSD) technology

Innovative, intelligent vacuum pumps

The GHS VSD+ Series is a range of new-generation,intelligent,

oil-sealed rotary screw vacuum pumps with Variable Speed Drive

(VSD) technology from Atlas Copco. Based on the well-known and

durable plug-and-play design principles of Atlas Copco compressors,

these vacuum pumps have been designed by vacuum engineers to

deliver peak performance at your operating pressure.These unique

products offer:

• Superior performance against benchmarked oil-sealed and dry vane

vacuum pump technologies.

• Increased efficiency – State-of-the-art screw technology,Variable

Speed Drive (VSD) and innovative motor design combine to produce a

leap forward in efficiency.

• Quiet operation – Noise level is far below that of comparable

technologies.

• Sustainable productivity thanks to built-in efficiency.

• Reduced environmental impact due to ultra-high oil retention at

all operating pressures.

Perfect for diverse markets

The GHS VSD+ Series vacuum pumps are ideal for a range of

applications in plastics, glass, bottling,canning, wood, packaging,

printing and paper,meat packaging and many more. The GHS 350-900

VSD+ is the ideal solution when a dedicated pump is required in the

production area. The GHS 1300-1900 VSD+ can also be set up as a

dedicated solution but is normally used in the plant room of

central vacuum system applications.

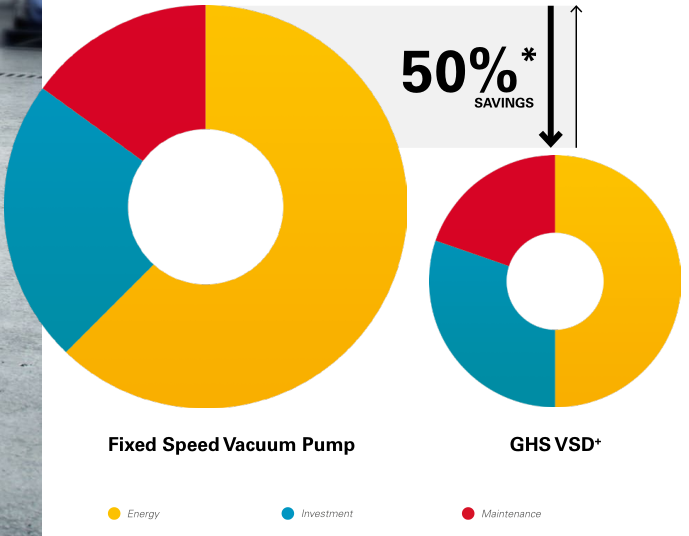

Low lifecycle costs

Here are two examples of the impressively low lifecycle costs of

the GHS VSD+ Series:

• For replacement pumps, the GHS VSD+ Series offers a very low lifecycle cost (including

service activities and energy).

Generally the payback time against existing oil-lubricated or

multiple dry vane installations will be much less than two years,

considering power and maintenance costs alone,without taking into

account the ease of installation.

Outstanding, unmatched benefits

With these vacuum pumps you can potentially save 50%* or more in

energy costs. They are among the

most energy-efficient oil-lubricated vacuum pumps on the market in

the capacity range where some other

technologies (e.g. oil-sealed vane) start to become mechanically

inefficient and expensive in terms of

capital expenditure.

As much as 90% of the electrical energy used by a vacuum solution

is converted into heat.

With Atlas Copco’s integrated energy recovery system, it is

feasible to recover up to 75% of that power

input as hot water without any influence on the machine’s

performance. Through efficient usage of the

recovered energy, you obtain important energy cost savings and a

high return on investment.

The innovative technology that makes it work

1.Element

• Highly efficient oil-sealed rotary screw.

• Outstanding performance in a robust design.

• Element life is significantly longer than screw compressors and

vane pumps.

2.Inlet control valve

Modulating vacuum control in conjunction with the VSD drive to

minimize energy consumption.

3.Atlas Copco’s Neos inverter(GHS 1300-1900 VSD+)

• Atlas Copco’s in-house designed inverter for VSD machines.

• A robust, aluminium enclosure for trouble-free operation in the

harshest conditions.

• Fewer components: compact, simple and user-friendly.

4.Guaranteed oil retention

• Optimum design for maximum oil retention.

• Longer life due to managed performance: the vacuum pump never

overloads the separators.

• Innovative and patented oil separator design retains oil at <3

mg/m3 even under the greatest load.

5.Energy recovery options

• Allowing you to recover up to 75% of the power input.

• Helping you to fulfil your energy management & environmental

commitments according to ISO 50001/14001.

6.Elektronikon® monitoring system

Elektronikon® is a state-of-the-art monitoring system for your

vacuum pumps. It is simple and comprehensive,and leads to energy

savings. It can also integrate your plant management system thanks

to a remote monitoring option.

7.Canopy with hot-cool zones

The GHS VSD+ Series features a canopy with a hot-cool design.It

isolates all heat producing and temperature critical components

(oil

separator and element) from all other components. As cool running

means higher reliability, this feature extends the lifetime of

electronic components and leads to a longer Mean Time Between

Maintenance (MTBM).

8.Easy to use, simple to maintain

• The top cover of the oil separator has a unique hinge

mechanism.It slips the cover to the side, allowing the oil

separator filter to be

changed easily and quickly.

• A cleverly designed exhaust pipe (drip drain leg) enables the

condensate to be collected in the discharge pipework at the outlet

and can be drained via the outside of the canopy.

VSD+ for potential energy savings of 50%* or more

In almost every production environment, the need for vacuum

fluctuates depending on different factors such as process changes,

the time of day, week or even month. Extensive measurements and

studies of demand profiles show that there are many

substantial variants with regards to vacuum demand.

Why Atlas Copco variable speed drive technology?

• Potential energy savings of 50%* or more with an extensive flow

range (10-100%).

• Reduced electrical installation costs (fuse and cable size).

• Integrated Elektronikon® Graphic controller controls the motor

speed and high efficiency frequency inverter.

• Eliminates peak current penalty during start-up experienced with

stop-start machines.

• EMC compliance to directives (2004/108/EG).

Numerous configurations to match your application

Choose the version that matches your specific application

requirements:

1.Standard

This machine focuses on delivering the exact performance you

demand,at the lowest possible lifecycle cost. Ideal for

applications where you need to maintain a set vacuum level (set

point).

2.Humid

Suitable for high water content duties (up to 100%),for

applications such as plastics, clay molding, drying pipelines,

salad cooling, freeze drying etc.Configuration for high water vapor

tolerance constitutes the humid version.

3.Turbo

This fast evacuation version enables faster cycle times – meaning

more production. It’s ideal for meat, cheese and chicken packaging,

as well as cooling, freeze drying and general vessel evacuation

applications.Turbo versions for fast cycling machines are available

in 350, 585, 730, 1300 and 1600 sizes and come with upgraded motors

and logic.

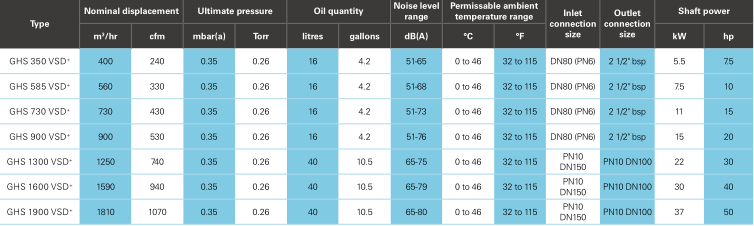

Technical Specifications:

Dimensions:

1.GHS 730 VSD+:

Height: 1100 mm

Width: 1300 mm

Depth: 900 mm

2.GHS 1300 VSD+:

Height: 1467 mm

Width: 1420 mm

Depth: 1585 mm