Anping County Xinlu Wire Mesh Products Co., Ltd. |

|

4-2500 Mesh Size Continuous Slot Wedge Wire Screen Pipe, Johnson Well Screen Tube

stainless steel vee sharped wire / wrap wire, johnson screeen, water well screen / rod based wire wrapped screen, wedge wire screen, reverse wedge wire screen, stainess steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, dewatering screen panel, wedge wire grating, v wire flat panel, screen nozzle, water and gas strainer nozzle, stainless steel filter nozzle, wedge wire support grids, sieve bend plate, v wire screens, ARC screen, filter bottom nozzle, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod basedc ontinuous slot screens, header and hub laterals & hub radial laterals etc.

SAND CONTROL WEDGE WIRE CONTINUOUS SLOT SCREEN PIPE

The continuous slot wedge wire screen pipe is widely used throughout the world for water, oil, and gas wells, and is the dominant screen type used in the water well industry.

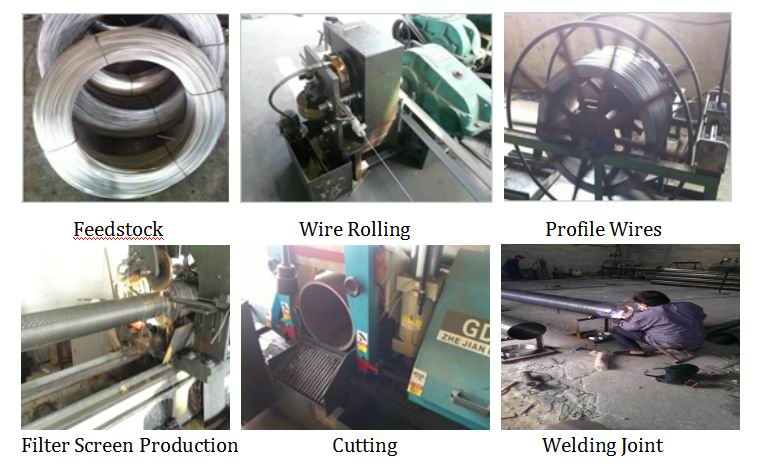

Xinlu continuous slot wedge wire screen pipe is made by winding cold-rolled wire, approximately triangular in cross section, and round a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics and minimum weights.

Slot opening for continuous slot wedge wire screen pipe are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be clean and free of burrs and cuttings.

Each slot opening between adjacent wires is v-shaped, from the special shape of wire used to form the screen surface. The v-shaped openings designed to be nonclogging, are narrowest at the outer face and widen inwardly. They allow more flow.

1. Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2. Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3. Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media

4. Low operational costs: Large open area with an effective flow, high yield and a low pressure drop

5. Long live: Welded at each intersections creating a strong and durable screen.

6. Reduced installation costs: Supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components

7. Chemical and thermal resistant. A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.

Each slot opening between adjacent wire is v-shaped, resulting from the special shape of the wire used to form the screen surface. The v-shaped openings, designed to be non-clogging are narrowest at the outer face and widen inwardly.

continuous slot wedge wire screen pipe provide more intake area per unit area of screen surface than any other type. For any given slot size this type of screen has maximum open area.

Slot size(mm): 0.10, 0.15, 0.25, 0.30-3, also achieved upon customer request.

Open area up to 60%

Material: Low carbon, low carbon galvanized steel(lcg), steel treated with plastic spraying, stainless steel (304, 316,etc)

Lengths up to 6meters

Diameter ranging from 25mm to 1300mm

End connection: Plain beveled ends for butt welding or threaded

SIZE (INCH) |

O.D (MM) |

SLOT (MM) |

LENGTH (M) |

COLLAPSE STRENGTH (BAR) |

TENSILE WEIGHT (TON) | WRAP WIRE(WIDTH*HEIGHT) (MM) | RODS (MM) |

| 3-1/2 | 88.9 | 1.0 | 3 | >22 | 10.2 | 2.3*3.5 | 3.8MM/22 |

| 4-1/2 | 114.3 | 1.0 | 3 | >28 | 11.5 | 2.3*3.5 | 3.8MM/22 |

| 6-5/8 | 168.3 | 0.75 | 5.8 | >40 | 12.8 | 2.3*3.5 | 3.8MM/32 |

| 6-5/8 | 168.3 | 1.0 | 5.8 | >33 | 12.8 | 2.3*3.5 | 3.8MM/32 |

| 6-5/8 | 168.3 | 0.63 | 5.8 | >83 | 45 | 3.2*6.0 | 6.0MM*32 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >34 | 21.9 | 2.3*3.5 | 3.8MM/48 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >50 | 38.2 | 3.0*5.0 | 4.0MM/48 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >60 | 46 | 3.2*6.0 | 5.0MM/48 |

| 10-3/4 | 273.1 | 0.75 | 5.8 | >50 | 32.9 | 2.3*3.5 | 4.9MM/55 |

| 10-3/4 | 273.1 | 1.0 | 5.8 | >60 | 39.5 | 3.0*5.0 | 4.9MM/55 |

| 10-3/4 | 273.1 | 1.0 | 5.8 | >100 | 48 | 3.2*6.0 | 5.0MM/55 |

| 12-3/4 | 323.9 | 1.0 | 5.8 | >120 | 37.2 | 3.0*5.0 | 4.0MM/50 |

| 14 | 355.6 | 1.0 | 3 | >80 | 37.8 | 3.0*5.0 | 4.0MM/59 |

| PROFILE WIRE | ||||||||

| WIDTH(mm) | 1.50 | 1.50 | 2.30 | 2.30 | 1.80 | 3.00 | 3.70 | 3.30 |

| HEIGHT(mm) | 2.20 | 2.50 | 2.70 | 3.60 | 4.30 | 4.70 | 5.60 | 6.30 |

| SUPPORT ROD | ROUND | |||||

| WIDTH(mm) | 2.30 | 2.30 | 3.00 | 3.70 | 3.30 | Ø2.5--Ø5mm |

| HEIGHT(mm) | 2.70 | 3.60 | 4.70 | 5.60 | 6.30 | ---- |

Advantages of Wedge Wire Screen Pipe:

Non-clogging capabilities

Self supporting

High abreaction resistance

Large open area

Better sand filtration

Energy saving

Lowest possible cost

Long using life

Maximum flow capacity

Use:

water well

water supply systems

Refining & petrochemical

Filter equipment

Drum Filter

Sand control

Groundwater

Pump Filter

Motor Filter

Dewatering

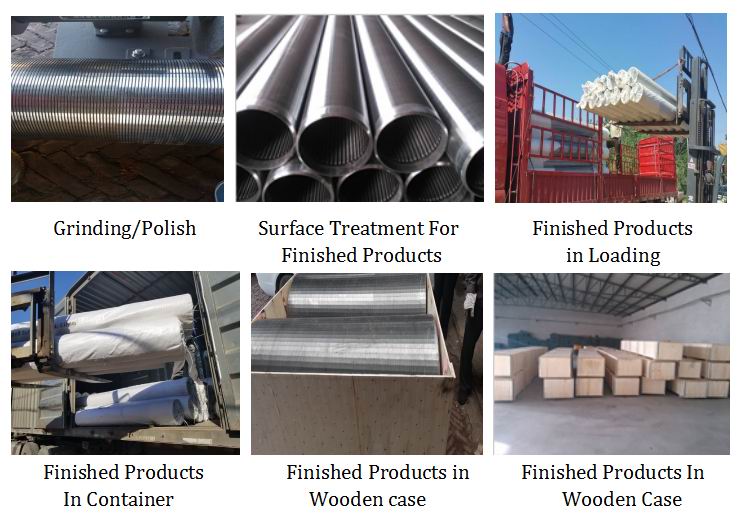

We can produce products according to the needs of our customers.

Material: stainless steel 304, 316L, low carbon steel

Diameter: minimum diameter 32mm, maximum diameter 1270mm

Length: single tube can be up to 6 meters in length

Gap: 0.25mm, 0.5mm, 0.7mm, 1.0mm, 1.5mm is a regular gap. We can

produce gaps of 0.1-50mm

Joints: Generally, there are joints at both ends of the pipe, such

as flanges, weld rings, or threads, so that the pipes can be

connected to meet

---------------------------------------------------------------------------------------------------------------

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.