HEFEI SAIMO EAGLE AUTOMATION ENGINEERING TECHNOLOGY CO., LTD |

|

CP180L Multi-Line Barrel Water Palletizer Robot For Liquor In

Beverage Industry

HIGH-SPEED PALLETIZING ROBOT

Designed specifically for palletizing applications, the Palletizer

Series features five unique robots with payload capacity from 80 kg

to 500 kg to suit most needs. With industry leading work range and

reliability, Kawasaki's high-speed palletizing robots help

companies improve production line efficiency.

FEATURES

Broad operating range and high payload capacity

The RD80N is the most compact model, but possesses a wide range of

movements. In addition, the RD80N stacks a maximum height of 2062.3

mm on 1100*1100 pallets.

Palletizing capacity worthy of our high-speed age

Kawasaki palletizing robots deliver the high-speed operation needed

for distribution. When moving a vertical distance of 400mm and a

horizontal distance of 2000 mm in a to-and-tro motion, the RD80N

can perform 900 cycles per hour with loads of 80kg. In the same

conditions the ZD130S is capable of performing 1500 cycles with

loads of 130kg, while the MD500N can do up to 600 cycles with loads

of 500kg.

No wasted action with the small installation space

RD80N has a turning radius of 397 mm, enabling it to cover a wide

working area at high speed while occupying less space than a

person. The MD500N features a unique new-type link mechanism for

the upper and lower arms, allowing for a compact body without a

counter weight.

Cubic-S which is an optional function to monitor the movement of

robots, can be used to limit the range of robot movements and make

safety fence area smaller.

Simple palletizing software K-SPARC(option)

Kawasaki’s palletizing software K-SPARC allows layout planning and

operations to be simulated on your computer. All you have to do is

simply start up your computer and select the workpieces, pallets,

and stacking patterns you want to use. You can also review layouts

displayed on screen as well as simulate robots. With its enhanced

usability, K-SPARC supports more pallet stacking patterns than

conventional palletizing software, making it easier to teach

robots.

ROBOTSPECIFICATIONS

| Degrees of Freedom | 4 axis | ||

| Payload | 180 kg | ||

| Work Envelope (degrees) & Maximum Speed (degrees/s) | Axis | Motion Range | Maximum Speed |

| JT1 | ±160° | 140°/s ✽4 | |

| JT2 | +95 - –46 | 125°/s ✽4 | |

| JT3 | +15 - –110 | 130°/s ✽4 | |

| JT4 | ±360° | 400°/s ✽4 | |

| JT5 | - | - | |

| Working area | Width | 1,800 mm | |

| Depth | 1,600 mm | ||

| Height | 2,200 mm | ||

| Moment of Inertia | 50 kg•m2✽4 | ||

| Palletizing capacity✽2 | 2,050 cycle / hour✽4 | ||

| Positional repeatability | ±0.5 | ||

| Mass | 1600 kg | ||

| Power requirements✽3 | 12 KVA | ||

✽2: Movement method (reciprocating by rising 400mm, horizontal movement 2,000mm, falling 400mm)

✽3: Depending on load and movement mode

✽4: If the load is less than or equal to 130kg

✽5: If the load is less than or equal to 250kg.

Package and Delivery

Machine film wrapped and packed in exported fumigation wooden box,

then transported to departure port which customer required like

Shanghai, Ningbo, Qingdao, Suzhou etc.

Why choose us

1. We will help you with the program of Kawasaki, and the basement

and grab hands.

So that you can easily use it.

2. Also, we will send our technician to your factory workshop to

train your operator until they know how to use.

3. We have done many projects of ABB robot palletizing together

with our packing and filling system to be a whole system. We have

many brands of robot, not only ABB, but also Kawasaki, Fanuc, Kuka

etc. and we can select the best suitable & cheapest robot model

for you.

Commission and After-sale Service

We make accurate factory layout design according to customer’s

factory size; if the customer needed, we could make workshop design

with electric power, water supply, gas power, material storage,

final storages, workers’ restroom, etc.

If customer need, we will send engineer for the commissioning

service. 1-2 of our engineer will

go to your factory to install and adjust the processing line to

realize normal production at shortest time.

Our engineers have responsibility to train and teach the workers

how to operate, clean, maintain the repair all the machine, until

the worker could well operate the production line.

It normally costs 10 days for the commissioning service, and we

supply 1-year guarantee from the date of completion of

commissioning service.

The engineer’s round-trip flight tickets, accommodation and daily

salary USD 60-100 are on client’s account.

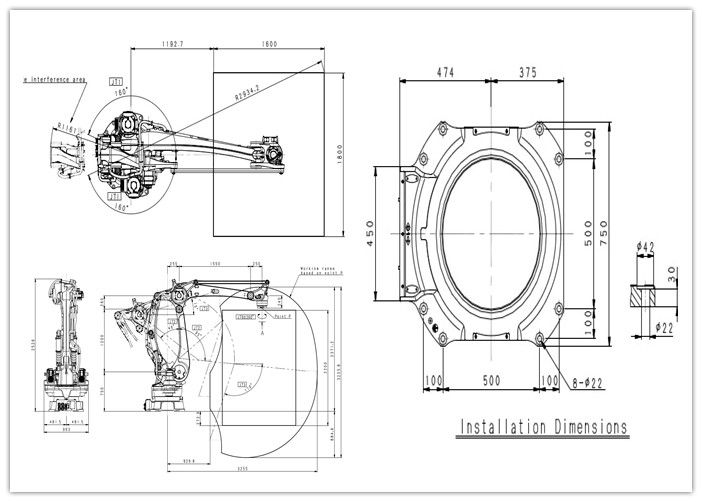

MOTION RANGE & DIMENSIONS

Customize Contact Us

You would like to know the detail offer of the machines, please

confirm your detail requirements (information as below) for the

whole project so that we can suggest the best suitable machine

model for you.

1. What's your product? Packed in bag or carton or others?

2. How many packages per hour?

3. Can you send me the layout of your current workshop? We have to

design the drawing of the whole line based on your workshop layout.

If no, please tell us the available sizes of your workshop.

4. What's the height of full pallet (without the empty pallet

thickness)?

5. What's the palletizing type (how many bags per layer, how many

layers per pallet, how the bags are put on each layer)?

6. What's the sizes (length, width, height) of empty pallet?

FAQ

Q: Do you offer Installation&debugging?

A: Our engineers are available to service machinery overseas to help customers to solve machine problems.

Q: what’s policy for guarantee and broken parts ?

A: As for machine products, our company provides 12 months for all

mechanical parts with the exception of electrical and electronic

parts and those subjects to normal wear and tear. Meanwhile, the

guarantee starts from the shipment (B/L date). The guarantee is

intended limited to the replacement of the broken part after

checking the construction fault. The inspection of the causes of

the trouble or the breakdown of the parts is exclusively up to the

manufacturing company. All in all, our company can offer you

assured products.

Q: What’s your terms of payment?

A: Payment is Less than or equal to1000USD, 100% in advance.

Payment is more than 1000USD, 30% T/T in advance, balance before

shipment.

Q: How do we test your machinery?

A: When the machine completely manufactured, we will send video for

check, and you also can come to our factory to test and learn how

to operate it.