ZHANGJIAGANG SAIJIA MACHINERY TECHNOLOGY CO.,LTD. |

|

Verified Suppliers

|

|

Plastic Pipe Manufacturing Machine 37Kw Pvc Pipe Extrusion Machine Line

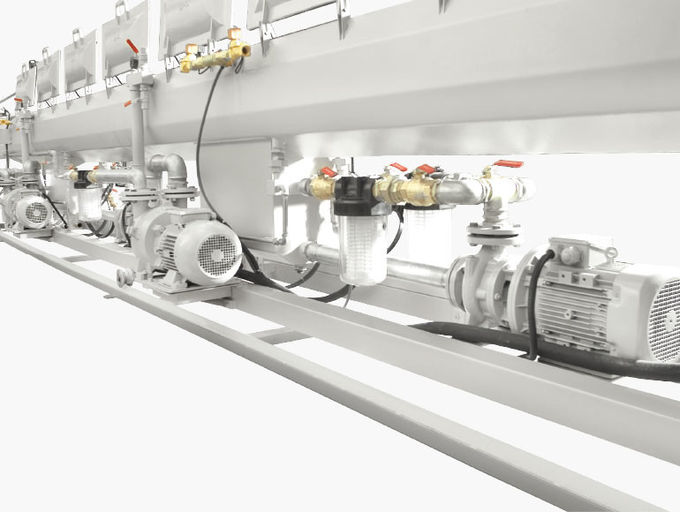

Description of Components:

1. Extruder: adopting conical twin-screw extruder, unique designed screw, realizing the shorting plasticizing time, good compounding and excellent plasticization.

2. Gearbox: adopting super quality gearbox and reducer, with a nice outline, stable running, low noise and long service time.

3. Extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

4. Screw and barrel: screw core installing with internal temperature controlling system, barrel equipped with vacuum degassing system can get rid of the waste gas from the raw material which can guarantee super quality of the products.

5. Driving system: adopting A.C motor, using FUJI or ABB inverters which provide stable torque output and various speed.

6. Vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the pipe, spraying water cooling, equipped with a temperature controller, realizing automatic discharging the water, the main body of the tank made of stainless steel, long service time.

7. Haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws, and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

8. Cutting unit: saw cutting and planet saw cutting, with the dust collection system.

9. Staking unit: automatic overturning system, can freely fix the length of the pipe.

10. Controlling system: manual controlling cabinet or SIEMENS PLC touch screen control.

Technical Parameter:

| Extruder | SJZ-65/132 | SJZ-80/156 | SJZ-92/188 |

| Pipe size | Φ16-Φ63MM | Φ50-Φ110MM | Φ90-Φ160MM |

| Mould | Double outlet | Double outlet | Double outlet |

| Downstream | GF63-2 | GF110-2 | GF160-2 |

| Total Power | 109.5KW | 145KW | 250KW |

| Total Length | 22.2M | 27M | 28.8M |

Overall Service:

| No. | Item | Details |

| 1 | Formula support | We provide basic formula to our customers for each project. And our engineers will help customers to do formula adjustment according to requirement. |

| 2 | Installation support | Our engineer will help customers to install the machines in Customer’s factory. |

| 3 | Operation support | We provide machine operation and maintenance training for our customers. |

| 4 | Fast response | We provide machine operation and maintenance training for our customers. |

Features Specifications:

1. Model SJZ series conical twin-screw extruder is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produce all sorts of PVC plastic pipe, profile, plate material, sheet material, bar material, and granulation.

2. The conical twin screws have applied the oil cooling system. Barrel is cooled by special wind cooling system.

3. The conical twin-screw extruder system has applied special computer control. According to customers requirements, most reasonable structure of conical twin-screw can be made so as to achieve the best plasticity performance and material quality.

4. The conical twin-screw is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced the advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear larger extruding pressure.

6. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems that can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1degree.