Dongguan Zhongli Instrument Technology Co., Ltd. |

|

Verified Suppliers

|

|

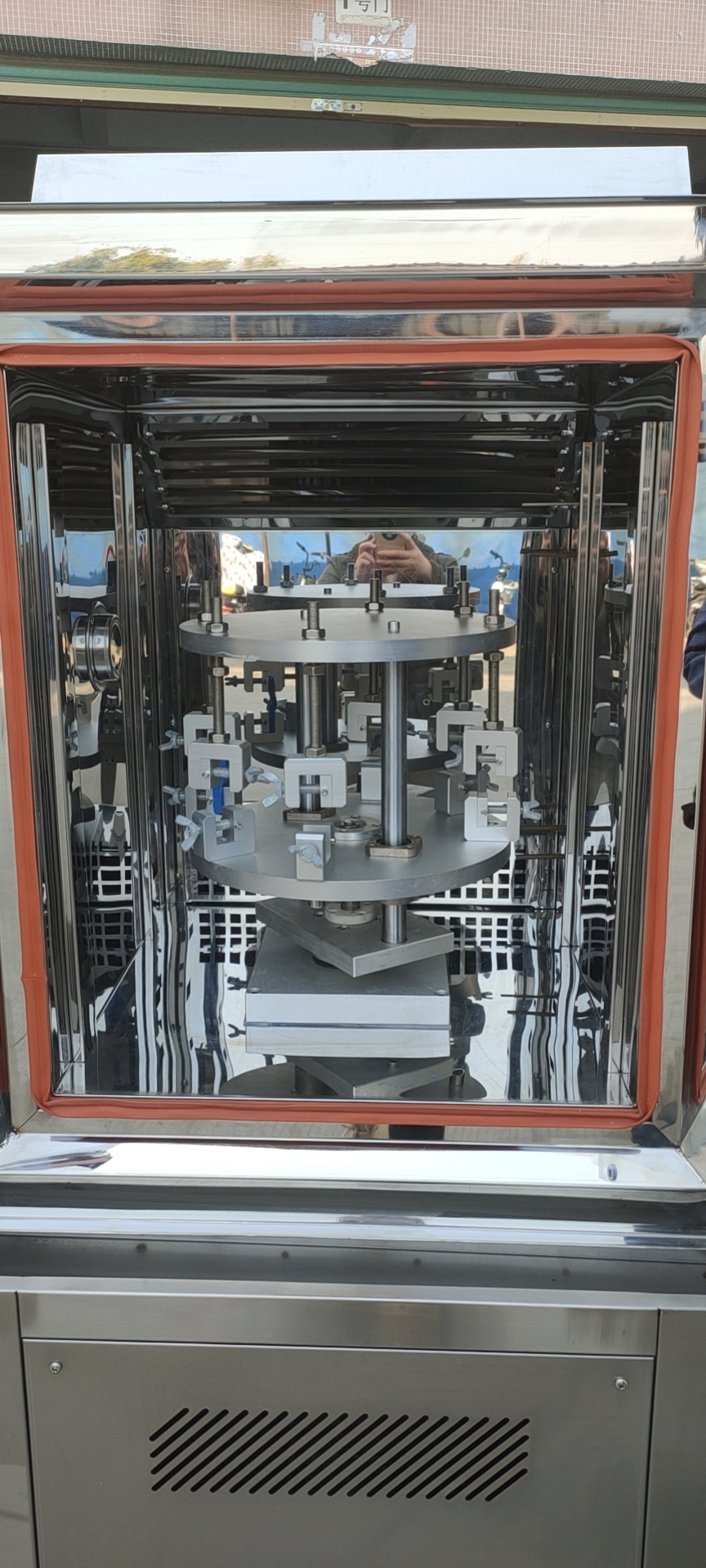

Equipment summary:

ZL-6018 Ozone-resistance testing machine.pdf

Ozone is a major factor in rubber cracking although it is rare in

the atmosphere, ozone aging tank simulates and enhance the

condition of ozone in the atmosphere to study the effects of ozone

on rubber, and then identify and evaluate the method to resist

ozone and aging for rubber, adopt effective anti-aging measures to

enhance the life of rubber products.

Corresponding standard:

JIS K 6259 ASTM1149 ASTM1171 ISO1431 DIN53509 GB7762 GB/T13642

Applicable industries:

It is widely used to control products quality in measuring quality

control; Rubber & Plastics; automobile production; wire and

cable; packing materials; instruments and meters; medical

equipment; civilian nuclear energy; civil aviation; colleges and

universities; research laboratories; inspection arbitration, and

technical supervision departments and other rubber products.

Technical Parameters:

| The Detailed Parameters of the Ozone Aging Test Chamber are as Follows: | |

| I. Product Performance: | |

| 1.1. Name | (Static) ozone aging tester |

| 1.2. Volume | 150L (L for liter) |

| 1.3. Inner Box Size | W500 X H600 x D500mm (W for width, H for height, D for depth) |

1.4.Outer Box Size About | Approx. W1000 X H1700 x D900mm (W for width, H for height, D for depth) |

| 1.5.Weight | Approx. 150kg |

| 1.6.Power Supply | AC220 ± 5% V/50 ± 0.5Hz |

| 1.7. Uses | The content of ozone in the atmosphere is very little but the main factor of rubber cracking, this product simulates and strengthens the ozone conditions in the atmosphere, to study the law of ozone action on rubber, to quickly identify and evaluate the performance of rubber anti-ozone-aging and anti-ozone-agent protection effectiveness of the method. Reference standards: GB/T7762-2014 static tensile test method for ozone cracking resistance of vulcanized rubber or thermoplastic rubber, GB/T2951.21-2008 general test method for cable insulation and sheathing materials, GB/T 11206-2009 surface cracking method for rubber aging test, and other test methods specified in relevant standards. |

1.8. Principles | The test method can be divided into "static" and "dynamic" according to the test method and standards, static means that the sample is stretched well or the product directly into the test chamber to do the test, dynamic is placed in the test chamber on the fixture, stretching the float for the tested sample itself about 5% -45%. |

| II. Main Technical Parameters: | |

| 2.1 Temperature Range | RT +10 ℃ - 60℃ (test ozone temperature can not exceed 60℃, ozone will automatically decompose quickly) |

| 2.2Temperature Fluctuation | ±0.5℃ |

2.3 Temperature | ±2.0℃ |

2.4. Humidity | 35%~95%R.H(Customer select optional requirements) |

| 2.5 Humidity Fluctuation | ±3.0%. |

2.6 Humidity | ±3.0%. |

2.7 Ozone Concentration | 0~1000pphm ±15% |

| 2.8 Test Gas Flow Rate | 600±100MM/S |

| 2.9 Rotation Rate of Shelf | 2±1r/min (adjustable). |

2.10 Number of | 3 groups of experiments can be conducted simultaneously |

2.11 Dynamic | 0-20HZ (Adjustable pull-up rate) |

| III. Structural Characteristics: | |

| 3.1. Structure | All-in-one. |

| 3.2. Material | Inner box: SUS304 stainless steel plate |

| 3.3. Door | Single door, left opening. |

3.4. Sample Holder | At both ends of the specimen to be tested, the specimen should be

tested in a direction essentially parallel to the direction of the

airflow when in contact with the ozonated air |

| 3.5.Control Panel | Controller display |

| 3.6. Box Configuration | Inside with a stainless steel SUS #304 shelf turntable |