INTER-CHINA RUBBER MACHINERY CO., LTD. |

|

Verified Suppliers

|

|

Mandrel Cutting Machine Double Cutters;

Cutting Machine for gaskets and washers;

Gasket Cutters; Seal Cutters;

Why choose US

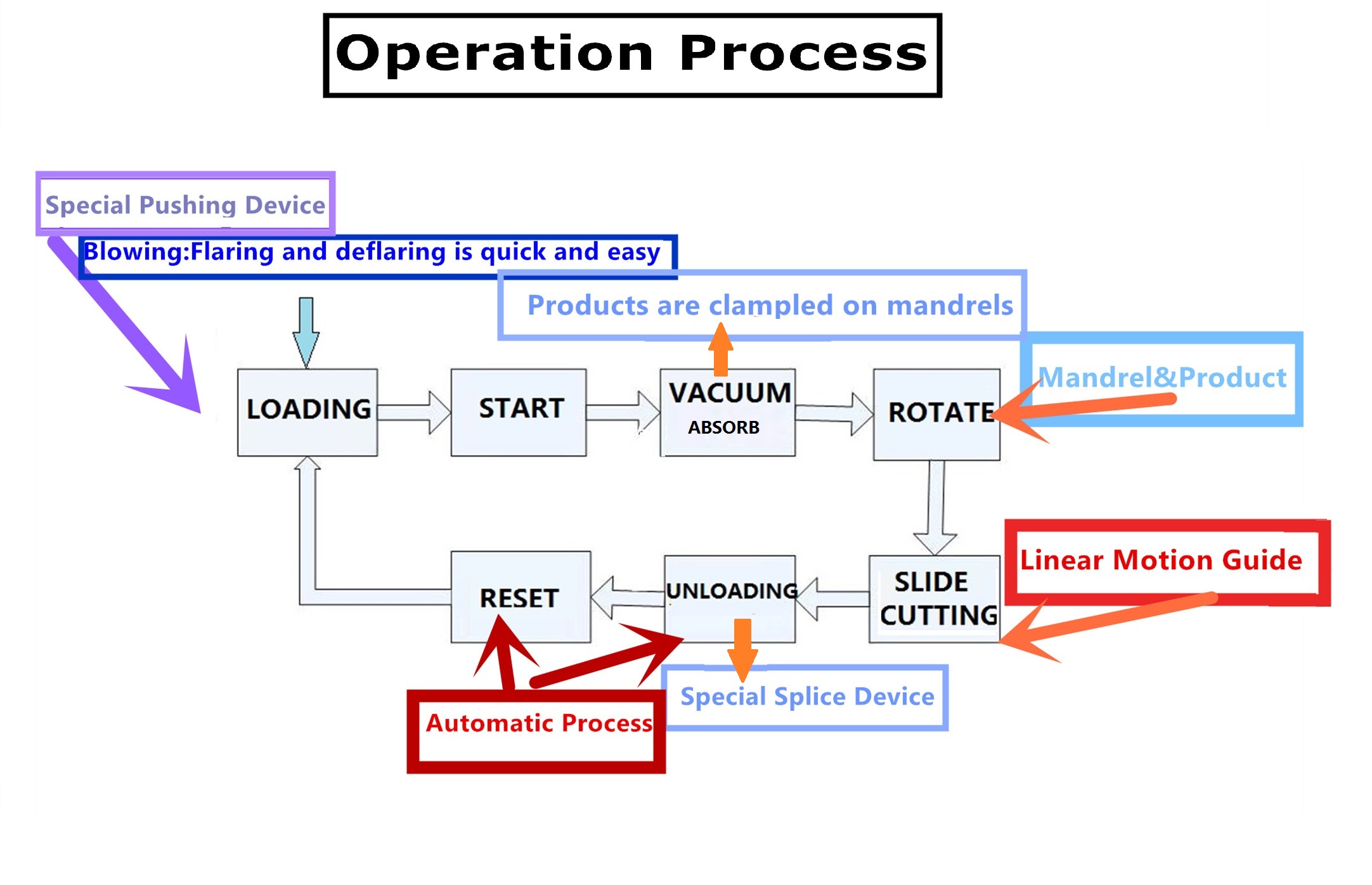

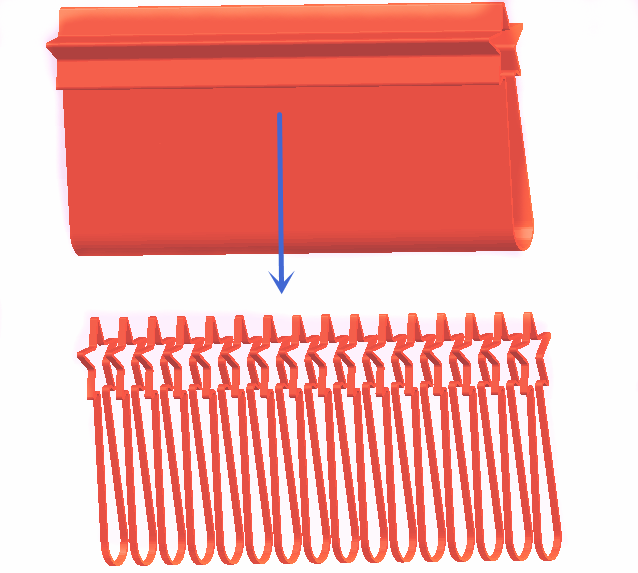

Machine Process Chart:

Process

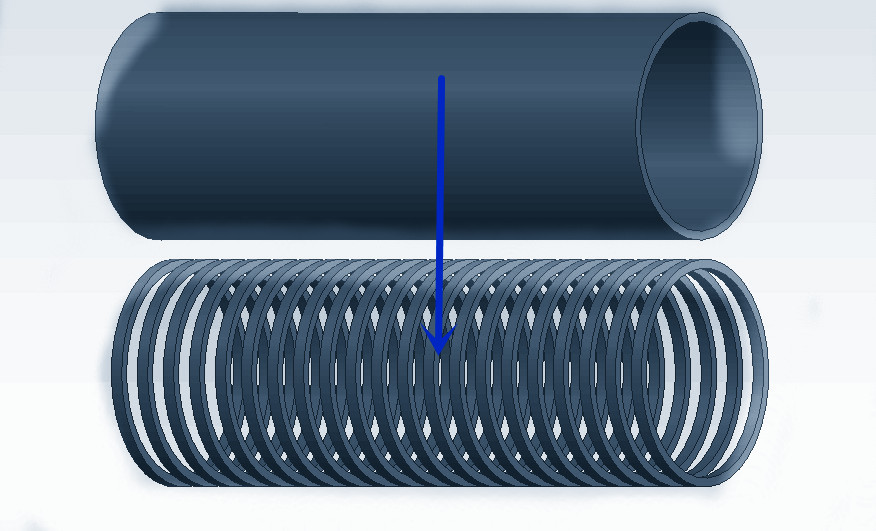

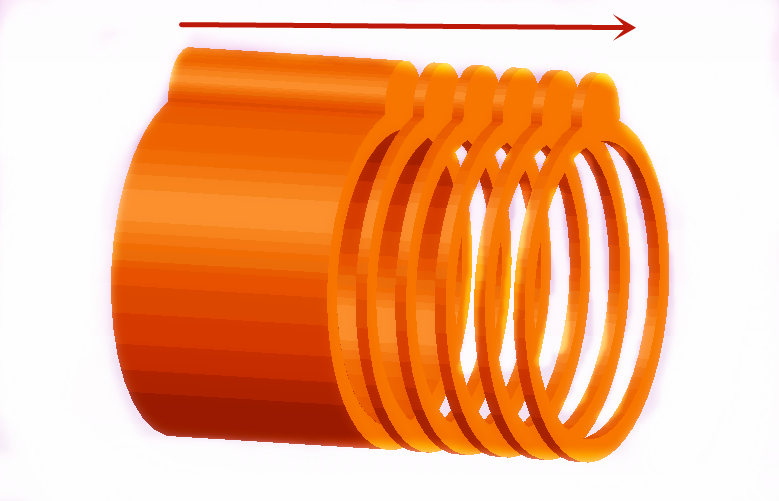

To produce the plain section gaskets, rubber tubes – already cut to length – are stretched onto mandrels. Loading and unloading of the tubes onto the mandrels is done quickly by a special unit and without any particular skill being required.

Applications & Advantages:

1. Can cut out a wide range of dimensions and thicknesses rings and slices …

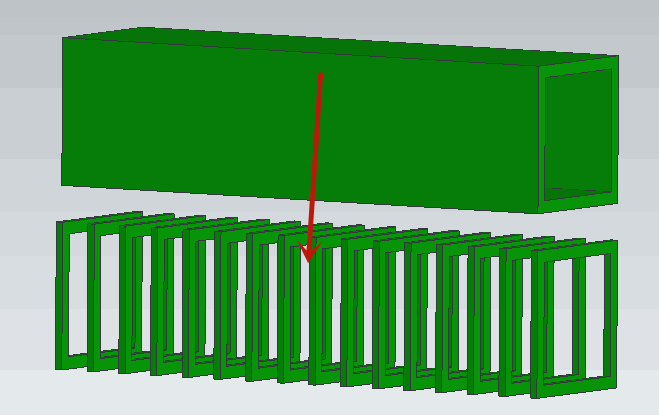

2. Both Regular shapes and irregular shapes rings and slices can be cut off….

3. Both molded/extruded pipes/tubes/hoses are possible to be cut...

4. A wide range of materials of Rubber/Plastic/polyurethane/Silicones /Latex /foam ….etc. Or similar hard & half-hard materials...

5. Multi-Mandrels structure realizes the exact high precision, large volume, and low cost.

Technical parameters:

| PERFORMANCE | |||

| Model No (Advanced Series ) | INC-200-2 | INC-400-2 | |

| Nos of Spindle/Mandrel | 2 | ||

| Cutting rate max. | 140 x 2 cuts/min | ||

| Mandrel Rotation Speed | 0~2800 r/min | ||

| Cutting Precision | ≤±0.03mm | ||

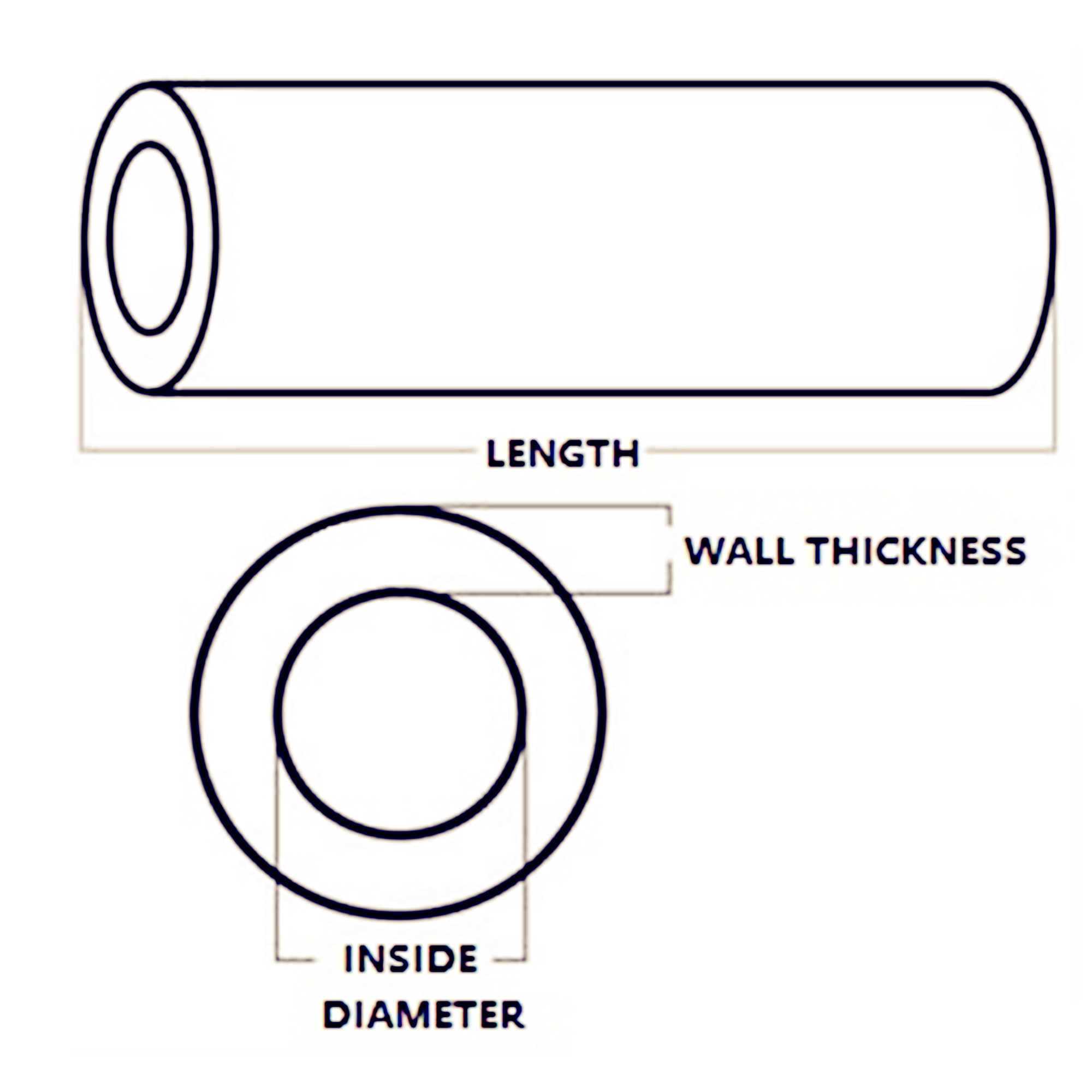

| Cutting ranges (Tailor-made is accepted) | Diameter | Φ2.8mm~Φ230mm | |

| Length | Standard≤150mm | Large sized≤350mm | |

| Thickness | ≤28mm | ||

| SPECIFICATIONS | |||

| Compressed Air Consumption | 20 L/min | ||

| Atmospheric Pressure | 0.5MPa~0.8MPa | ||

| Working Vacuum Degree | ≤-0.035MPa | ||

| Power Source | 1.Single Phasex220V/50/60Hz±5% 2.Three Phase x380V/50/60Hz±5% | ||

| Total Power | 2.5~3KW | ||

| Device Weight | ≈520 KGS | ≈580 KGS | |

| Device Size (L×W ×H) | 1280×900×1650mm | 1280×900×1650mm | |

| SPARE PARTS | |||

| Cutting Tools | (1) circular knife:Φ60×Φ25.4×0.35mm | ||

| (2) strip knife:65×7×0.3mm | |||

| Cutting Mandrel/spindle | fit product size for cutting | ||

Reference: daily 40,000~60,000 gaskets can be finished.

Order Options:

Nos of mandrel: 1/2/3/4 are available;

Machine Painting Color;

Range of Cutting Length;

Range of Cutting Diameter;

Water cooling system;

Tail Bracket (As the supporting device for longer-length products)

Auxiliary pushing device for loading;

Auxiliary splice device for unloading;

Tags:

Mandrel Cutting Machine; Slicing Cutting Machine; Precision

machines for cutting off rings and slices;Oil filter sealing

gasket-making machine; Slice machine; Slicer; Circular knife

cutting machines for cutting gaskets;

Rubber gasket cutting machine; Gasket making machine; Rotary style

gasket cutter; Rotary cutting machine;

Rubber slitting machine; Machines for hose and tube processing;

Cutting machine for hoses and tube processing;

Machine for rubber and plastic processing; Cutting machine for gaskets and o-rings;

For more details, please get in touch with us freely !!!

CONTACT INFOS

Person: Susanna

INTER-CHINA RUBBER MACHINERY CO., LTD.

www.rubbermachinery-china.com

Mob:+0086-13179487165

SKYPE: rubber cutting

Email: info@rubbermachinery-china.com