Hongum Technology (Shanghai) Co., Ltd |

|

Verified Suppliers

|

|

Regulating Pneumatic Valve Diaphragm Sleeve Double Seat Valve Diaphragm

The installation steps of the pneumatic valve diaphragm are as follows:

1. Put the spring on the spring seat.

2. Install the diaphragm. When the diaphragm and the hard core are fixed, a loosening pad should be added to the screw cap to ensure that the diaphragm is flat and air-proof.

3. Therefore, grease should be applied to the fastening bolts before assembly, which is conducive to the next maintenance and lubrication.

4. Put on the upper membrane cover, fix it with a pair of eyebolts, and evenly and alternately tighten the eyebolts to complete the initial adjustment of the spring.

5. Tighten the fixed explosion nut on the membrane cover, and do not screw the eyebolt.

6. Install the connecting parts, and connect the supply line to the upper membrane cover.

7. After the above steps are completed, apply the following methods to verify:

1) Through the air supply line, the membrane air chamber is passed into the air supply pressure of 500KP, and use soapy water to check whether there is air leakage around the membrane.

2) Check whether the execution is flexible within the full stroke range (referring to the actuator itself).

Introduction:

Pneumatic valve adjustment diaphragms are simply referred to as

"pneumatic valve diaphragms." Pneumatic valve diaphragms are

usually butterfly-shaped, with their sidewalls gradually drawn from

the cylinder to the piston. It can be designed as a double layer to

withstand pressure in both directions. Due to its wide convolution

and tapered side walls, its ability to withstand high pressures is

limited. The effective pressure will also change during the

mid-range process.

Both the piston and flange of the pneumatic valve diaphragm are

molded in the same place. The advantage of this type of diaphragm

is that there is no need to manually swivel, which greatly reduces

assembly time. This is especially important in high volume

applications. The downside of this model is that due to the cast-in

swing, the redesign must take into account the built-in elastic

stiffness, as well as the stroke limit ratio. To increase this

ratio, a pre-convolution diaphragm can be designed for offset. In

this shape, the piston crown and flange are cast to counteract each

other, transferring the extra stroke capacity to one side of the

swing. This allows the diaphragm to have a longer stroke capability

while maintaining ease of assembly.

Quick details:

| Product Materials | NBR,NR |

| Operating Temperature | -20℃~80℃ |

| Service Life | ≥1000000 times |

| Usage Scenario | Industrial mechanical cylinder |

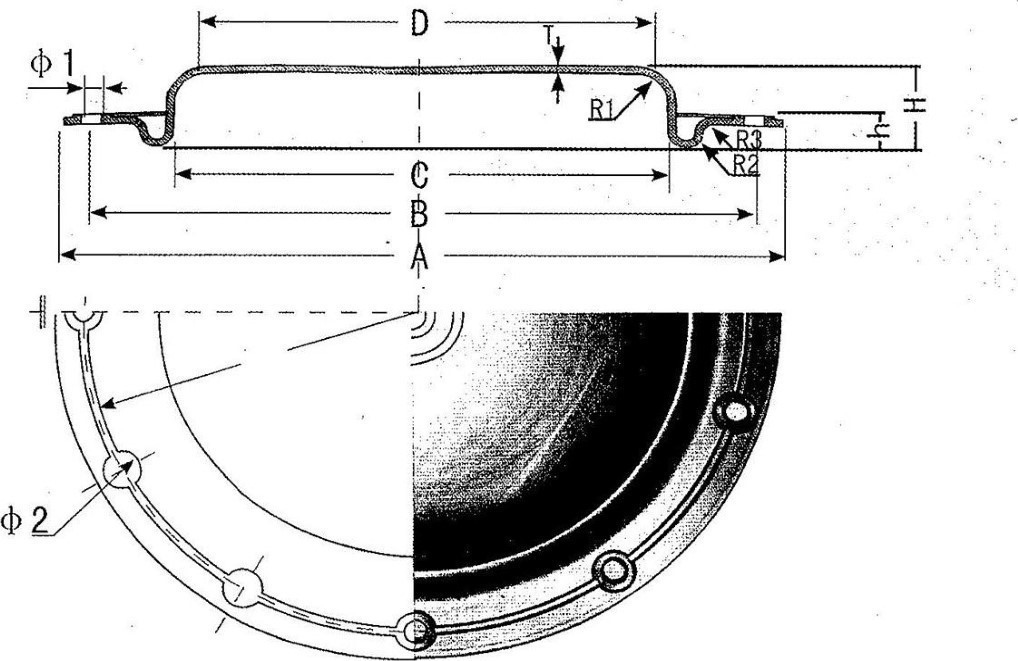

| item | Operating area | size | |||||||||||

| A | B | C | D | h | H | T | R1 | R2 | R3 | φ1 | φ2 | ||

| ZMLB-0 | 35 | 130 | 126 | 95 | 75 | 1 | 20 | 1 | 6.5 | 6.5 | / | 8×φ5 | / |

| ZMLB-1 | 50 | 145 | 130 | 90 | 80 | 4 | 7 | 2 | 8 | 8 | 8 | 8×φ7 | 8×φ12 |

| ZMLB-2 | 80 | 165 | 150 | 100 | 85 | 7 | 15 | 2.5 | 7 | 8 | 8 | 8×φ7 | 8×φ13 |

| ZMLB-3 | 70 | 195 | 175 | 120 | 96 | 18 | 25 | 2 | 6.5 | 4.5 | 6.5 | 10×φ8.5 | / |

| ZMLB-4 | 90 | 200 | 187 | 115 | 90 | 8 | 25 | 3 | 12 | 15 | 12 | 8×φ9 | / |

| XKK-1 | 230 | Nonporous | 175 | 150 | 5 | 15 | 1.5 | 12 | 6 | 12 | Nonporous | Nonporous | |

| XHD-1 | 255 | 225 | 140 | 120 | 7… | 16 | 2 | 3 | 17 | 14 | 12×φ9 | / | |

| XDG-1 | 255 | 235 | 175 | 155 | 10 | 50 | 3 | 7 | 5 | 10 | 12×φ9 | / | |

| ZMLB-5 | 250 | 255 | 245 | 190 | 160 | 8 | 38 | 3 | 11 | 7 | 15 | 12×φ6 | 12×φ12 |

| ZMLB-6 | 200 | 268 | 243 | 195 | 154 | 18 | 33 | 1.5 | 10 | 6.5 | 6.5 | 12×φ13 | |

| ZMLB-7 | 250 | 288 | 270 | 180 | 160 | 28 | 28 | 4 | 8 | 11 | 8 | 14×φ8.5 | / |

| ZMLB-8 | 350 | 338 | 312 | 250 | 211 | 23 | 45 | 2.5 | 9.5 | 6.5 | 8.5 | 18×φ10 | / |

| ZMAB-10 | 100 | 194 | 174 | 130 | 110 | 5 | 15 | 2 | 5 | 8 | / | 8×φ9 | 8×φ15 |

| ZMAB-1A | 150 | 205 | 185 | 135 | 115 | 10 | 24 | 2 | 5 | 7 | 12 | 8×φ9 | 8×φ15 |

| ZMAB-1B | 200 | 235 | 215 | 155 | 135 | 12 | 20 | 2.5 | 6 | 9 | 10 | 12×φ9 | 12×φ15 |

| ZMAB-2 | 280 | 285 | 265 | 195 | 155 | 8 | 33 | 2 | 12 | 12 | 15 | 12×φ9 | 12×φ15 |

| XDG-2 | 298 | 278 | 220 | 195 | 10 | 60 | 3 | 10 | 8 | 10 | 12×φ9 | / | |

| ZMAB-3A | 400 | 306 | 286 | 256 | 196 | 8 | 38 | 2 | 9 | 9 | 9 | 12×φ9 | 12×φ15 |

| ZMAB-3B | 420 | 325 | 305 | 220 | 180 | 18 | 45 | 3 | 8 | 15 | 10 | 16×φ9 | 16×φ15 |

| ZMAB-4A | 630 | 410 | 386 | 275 | 225 | 18 | 60 | 3 | 10 | 14 | 14 | 16×φ11 | 16×φ15 |

| ZMAB-4B | 600 | 394 | 374 | 290 | 230 | 18 | 60 | 2.5 | 12 | 14 | 14 | 16×φ11 | 16×φ15 |

| XDG-2 | 395 | 375 | 320 | 300 | 15 | 80 | 3 | 13 | 7 | 10 | 16×φ11 | / | |

| ZMAB-5 | 1000 | 195 | 470 | 365 | 295 | 16 | 70 | 3 | 20 | 26 | 30 | 20×φ11 | 20×φ18 |

| ZMAB-6A | 1600 | 616 | 586 | 460 | 360 | 45 | 100 | 4 | 14 | 20 | 20 | 20×φ11 | 20×φ16 |

| ZMAB-6B | 1600 | 640 | 610 | 460 | 360 | 46 | 102 | 4 | 14 | 20 | 20 | 24×φ12 | 24×φ18 |

| S1 | 70 | 176 | 156 | 100 | 72 | 10 | 33 | 3 | 9 | 9 | 10 | 12×φ9— | 12×φ14 |

| S2 | 100 | 195 | 175 | 110 | 80 | 13 | 35 | 2.5 | 7 | 10 | 14 | 12×φ⁹ | 12×φ14 |

| ZMAB-22 | 350 | 285 | 265 | 220 | 190 | 0 | 35 | 2 | 10 | 12 | / | 12×φ9 | 12×φ15 |

| ZMAB-23 | 350 | 285 | 265 | 220 | 190 | 0 | 48 | 2 | 10 | 12 | / | 12×φ9 | 12×φ15 |

| ZMAB-34 | 560 | 360 | 336 | 285 | 235 | 0 | 65 | 2.5 | 10 | 14 | / | 16×φ15 | |

| ZMAB-45 | 900 | 470 | 440 | 370 | 300 | 0 | 98 | 3 | 20 | 26 | / | 18×φ11 | 18×φ18 |

| HA-2 | 267 | 248 | 190 | 160 | 10 | 39 | 2 | 13 | 8/8 | 13 | 10×φ9 | 10×φ15 | |

| HA-3 | 350 | 330 | 265 | 225 | 12 | 50 | 2 | 12 | 8 | 18 | 16×φ9 | 16×φ15 | |

| xzs-1 | 126 | 114 | 96 | 74 | 0 | 10 | 3 | 0 | 10 | 10 | 6×φ7 | / | |

| XZS-2 | 135 | 122. | 103 | 78 | 0 | 15 | 3 | 0 | 7 | 7 | 6×φ7 | / | |

| XZS-3 | 186 | 172 | 150 | 112 | 0 | 15 | 3 | 0 | 15 | 20 | 8×φ7 | / | |

| XZS-4 | 234 | 218 | 194 | 153 | 0 | 18 | 3 | 0 | 10 | 10 | 12×φ7 | / | |

| XDY-1 | 110 | 108 | 95 | 80 | 0 | 20 | 3 | 0 | 45° | 3 | φ8 | ||

| XDY-2 | 150 | 147 | 132 | 100 | 0 | 22 | 3 | 0 | 45° | 4 | φ8.5 | ||

Our service:

1. Packaging is neutral packing or customized packing.

2. We will reply you within 24 hours.

3. We will also provide you with good after-sales service.

4. OEM or ODM orders are welcomed.

5. Trial orders are acceptable.

6. High quality and factory price.

7. 100% ensured the quality.