SHANGHAI ROYAL TECHNOLOGY INC. |

|

Verified Suppliers

|

|

PC + ABS LED light Reflector Aluminum Metallization, LED lighting High Reflection Film PVD Deposition

Finishing Properties: metal PVD chrome on PMMA (Acrylic) surface,

which generates the outstanding coating layers as below: During the

day time, sign symbols look like solid metal ( stainless steel

effect);

while at night, they are illuminated ( LED light inside is

installed ) from front, back and side views.

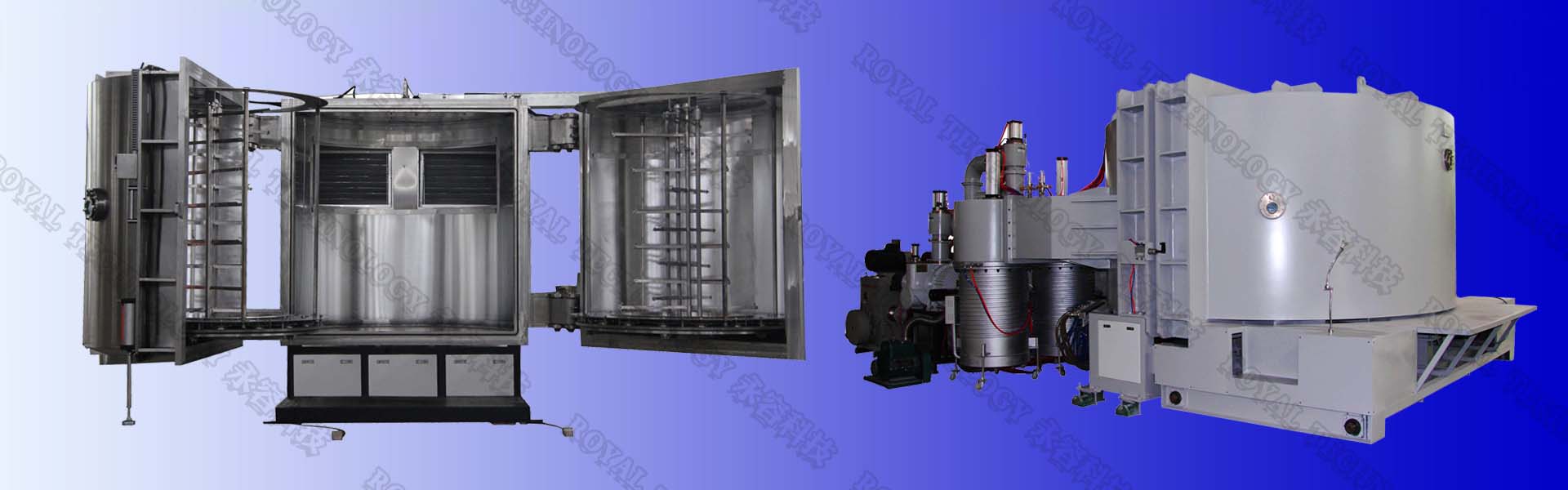

Thermal Evaporation Coating Unit Working Theory

About Thermal Evaporation Filament Technology: It Introducing the work pieces into the vacuum chamber, when the chamber's vacuum pressure is up to 5.0*10-2~8.0×10-3Pa with different stage of vacuum pumps ( Rotary Piston Vacuum Pump, Rotary Vane Pump, Roots Vacuum Pump,Diffusion Pump) , and then evaporate the Chrome filaments which hold in the tungsten filament ( or board). When the work pieces are turning around in a rotary driving system, the chrome material would deposit on the substrates surface and generate a highly uniform coating layer.

Metal perfume packing parts Billboard Thermal Evaporation Coating Unit Models:

| RTEP3618 | Φ3600xH1700 | 1 | 80 | 8x10-4Pa | 10'~15' depends on Product | 3Phase/AC380V,50HZ 3Ph, 220 to440V,60HZ | |

| RTEP2215 | Φ2200xH1500 | 1 | 50 | 10 | |||

| RTEP2525 | Φ2500xH2500 | 3 | 50 | 20 | |||

| RTEP6638 | L6600xH3800 | 100 | 20 | ||||

| RTEP4532 | L4500xH3200 | ||||||

PVD Vacuum Metallizing Machine Models and Specifications

| Description | RTEP1000 | RTEP1418 | RTEP1616 | RTEP1820 | |

| Deposition Chamber | mm | φ1000 x H1000 | φ1400 x H1800

| φ1600 x H1600 | φ1800 x H2000

|

| Door Structure | set | 1 | 2 | 2 | 2 |

| Evaporation Sources | pcs | 16 | 20~28 | 24 | 32 |

| Number of Satelites | rods | 6 | 6,8 | 6,8,10 | 6,8,10, 12 |

| Effective Coating Area | mm | φ280 *6*H800 | φ420*6*H1600 φ350*8*H1600 | φ490*6*H1400 φ400*8 *H1400 | φ560*6*H1800 φ460*8*H1800 |

| Cycle Time | min. | 10~12 | 15 | 15 | 15~20 |

| Evaporation Power Supply | kVA | 20 | 30 | 35 | 40 |

| Plasma Cleaning Power Supply | kVA

| 7 | 10 | 10 | 10 |

| Ultimate Vacuum | 8.0*10-4 Pa | ||||

| Pumping Speed | from atm to 9.0×10-3Pa≤10minutes ( @ room temperature, clean and unloading) | ||||

| Rotary Piston Pump Capacity | L/S | 70 | 150 | 150 | 150 *2 |

| Roots Pump Capacity | L/S | 300 | 600 | 600 | 1200 |

Difussion Pump Capacity (with cold trap) | L/S | 6000 | 8000 | 8000 | 2*8000 |

| Holding Pump Capacity | L/S | 15 | 30 | 30 | 70 |

| Approximate Maxium Power | KW | 50 | 75 | 75 | 110 |

Approximate Average Power

| KW | 25 | 35 | 35 | 60 |

| Approximate Weight | KG | 4500 | 7300 | 9000 | 11000 |

| Foot print (LxWxH) | mm | 3000*3000*2200 | 5000*4000*3500 | 6000*5500*3200 | 6500*6000*3800 |

Royal Technology provides you the turnkey coating solutions and facilities. Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.