Zhejiang Tianyang Rotational Technology Co.,Ltd. |

|

Verified Suppliers

|

|

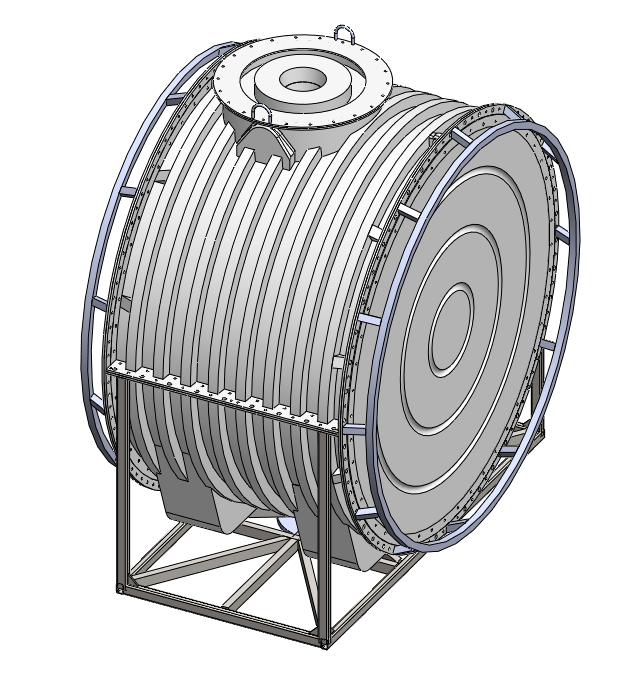

Polished Rotomolding Equipment / Rotational Mold Lightweight Custom Rotation Molding Short Lead Time

The Rotational Mold is an exceptional product designed by a Specialized Rotational Mold Manufacturer, whose expertise is reflected in every aspect of this state-of-the-art tooling. As an essential component of a water tank making machine, this mold boasts attributes that set it apart in the manufacturing industry, ensuring a seamless and efficient production process.

One of the most critical features of this Rotational Mold is its excellent corrosion resistance. Thanks to the high-quality materials selected by the manufacturer and the advanced treatments applied to the mold's surface, users can expect a mold that withstands the harsh chemicals and environments typically associated with the rotational molding process. This corrosion resistance is vital for maintaining the integrity of the mold over numerous cycles, thereby reducing the need for frequent replacements and maintenance.

Another significant benefit of this mold is its polished surface finish. The meticulous polishing process not only imparts a sleek and professional appearance but also plays a crucial role in the demolding phase of production. The polished surface allows for the finished products—such as water tanks—to be released from the mold with ease, minimizing the risk of defects and ensuring that every product meets the highest quality standards.

When it comes to durability, the Rotational Mold exhibits high resilience to wear and tear. This durability is a testament to the manufacturer's commitment to using only premium materials and the latest technologies in the production of their molds. The robust construction of the mold ensures that it can withstand the mechanical stresses and thermal cycles typical of a shuttle rotational moulding machine. As a result, this mold is an ideal choice for businesses looking to invest in reliable and long-lasting tooling for their manufacturing needs.

The manufacturer of this Rotational Mold is a leader in the field of rotational molding, with a focus on producing molds that offer long-lasting mold life. The longevity of the mold is not an accident but a product of deliberate design choices and stringent quality control measures. This focus on longevity ensures that the mold remains a valuable asset for an extended period, providing a high return on investment for the purchaser. The long mold life also means that the production of items, such as water tanks, can continue uninterrupted, enhancing productivity and profitability.

Moreover, the Rotational Mold is specifically engineered to work seamlessly with shuttle type rotomoulding machines. The shuttle rotational moulding machine is known for its efficiency and versatility, and this mold is crafted to complement those strengths. It is designed to accommodate the machine's unique movement and heating requirements, ensuring a smooth manufacturing process and high-quality output. The synergy between the mold and the machine translates to reduced cycle times and increased production capacity, making it an indispensable tool for manufacturers seeking to scale up their operations.

In conclusion, the Rotational Mold from our Specialized Rotational Mold Manufacturer is a pinnacle of design and craftsmanship. With its excellent corrosion resistance, polished surface finish, high durability, and compatibility with shuttle type rotomoulding machines, this mold represents the ideal choice for businesses aspiring to excel in the rotational molding industry. Investing in this long-lasting, high-quality mold means investing in the future of your company's production capabilities, ensuring a stream of flawless products and satisfied customers for years to come.

| Parameter | Specification |

|---|---|

| Manufacturer | Specialized Rotational Mold Manufacturer |

| Production Process | Rotational Molding |

| Corrosion Resistance | Excellent |

| Durability | High |

| Shape | Round |

| Lead Time | Short |

| Application | Plastic Products, including water tank making machine, shuttle type rotomoulding machine |

| Weight | Lightweight |

| Cost | Affordable |

| Size | Customized |

The Tianyang Rotational Molding products, originating from Zhejiang, are an epitome of durability and versatility. These products are developed through a sophisticated production process known as rotational molding, which ensures a uniform, polished surface finish and excellent corrosion resistance. The rotational molding technique is specifically advantageous for creating large, hollow objects that can be used in a multitude of applications and scenarios.

One of the prime application occasions for the Tianyang Rotational Molding products is the storage and transportation of various chemicals. Given the superior corrosion resistance of these products, they are ideal for holding corrosive substances without degrading over time. Industries that handle hazardous materials can benefit from the custom rotational molding services offered, tailoring the products to their specific needs.

Another scenario where these products shine is in outdoor settings. The long-lasting mold life ensures that items such as outdoor furniture, playground equipment, and recreational items withstand the elements and retain their aesthetic appeal. The polished surface not only contributes to the visual appeal but also makes cleaning and maintenance a breeze. Customization options further allow for the creation of unique designs that fit the specific branding or thematic requirements of parks, schools, or public spaces.

Additionally, the Tianyang Rotational Molding products are an excellent choice for the automotive and marine industries. Custom solutions can be developed using the shuttle rotational moulding machine to create durable and resilient parts such as fuel tanks, dashboards, and buoys. These items benefit from the uniform wall thickness and robust nature of the rotationally molded products, ensuring they perform well under stress and variable conditions.

In the field of agriculture, farmers can utilize large tanks and containers made through the shuttle rotational moulding machine for water storage, feed troughs, or even as part of irrigation systems. The ability to withstand environmental conditions and the longevity of the products make them a cost-effective solution for the agricultural sector.

Furthermore, Tianyang Rotational Molding products are also used in the construction of playgrounds and sports complexes. Their ability to be molded into various shapes and sizes, combined with the customization available, allows for the creation of unique and safe components that can be enjoyed by children and athletes alike.

In summary, the Tianyang Rotational Molding products offer a plethora of applications, from industrial storage, outdoor recreation, automotive and marine parts, to agricultural and playground equipment. The combination of excellent corrosion resistance, polished surface finish, and the option for customization makes them a preferred choice across various industries, ensuring that no matter the scenario, these products will perform exceptionally well for an extended period.

Welcome to Tianyang Rotational Molding , your premier destination for top-notch rotational molding molds . Crafted with precision in Zhejiang , our molds are synonymous with affordability and quality. Experience the pinnacle of cost-efficiency with our affordable rotational molds.

Our molds boast exceptional temperature resistance , sustaining up to 300 degrees Fahrenheit to meet the demands of various industries. The lightweight design of our molds ensures easy handling and operation, particularly with shuttle rotational moulding machines .

Designed to perfection, each mold features a round shape, which is a staple in rotational molding. The use of aluminum material not only contributes to the mold's lightness but also ensures durability and a consistent quality in your finished products. Choose Tianyang Rotational Molding for all your rotational mold needs and elevate the standard of your products.

Our Product Technical Support for the Rotational Mold product encompasses a comprehensive suite of services designed to ensure the optimal performance and longevity of your equipment. Our dedicated team of experts is committed to providing you with the highest level of service and support.

We offer a range of services, including installation guidance, operational training, and maintenance advice. Our technical support also covers troubleshooting assistance to help you quickly resolve any operational issues you may encounter with your rotational mold.

To help you maintain the highest standards of quality and efficiency, we provide regular updates and tips on best practices for the use of your rotational molding equipment. We also offer advice on material selection and mold design to maximize the potential of your product output.

For any service-related inquiries or technical challenges, our support team is available to provide you with the solutions you need to keep your operations running smoothly. We are committed to ensuring that you can leverage the full capabilities of your Rotational Mold product.

Product Packaging for Rotational Mold Product:

Each rotational mold product is securely encased in a protective polyethylene foam layer to prevent scratches and damage during handling. The foam-wrapped product is then placed into a heavy-duty corrugated cardboard box, tailored to the product's dimensions for a snug fit, ensuring minimal movement. The box is sealed with industrial-strength packing tape for additional security and integrity of the package throughout the shipping process. Fragile stickers and appropriate labels indicating the product's orientation are affixed to the exterior to further guide safe handling.

Shipping for Rotational Mold Product:

The packaged rotational mold product is shipped using a reputable courier service with a proven track record for handling industrial goods. Each package is registered with a unique tracking number, allowing for real-time monitoring of the shipment's progress from departure to delivery. The product is shipped under a freight insurance policy to protect against potential transit damage or loss, providing peace of mind for both the sender and the recipient. Delivery times may vary depending on the destination, and expedited shipping options are available upon request.

Q1: What materials are used in Tianyang Rotational Molding products?

A1: Tianyang Rotational Molding products are typically made from high-quality polyethylene, polypropylene, and other plastics suitable for rotational molding processes, ensuring durability and longevity.

Q2: Can I customize the shape and size of my rotational molded product from Tianyang?

A2: Yes, Tianyang Rotational Molding offers customization options for shape and size to meet your specific requirements. Please contact us with your design specifications for further assistance.

Q3: What industries does Tianyang Rotational Molding serve?

A3: Tianyang Rotational Molding serves a wide range of industries including automotive, marine, agricultural, industrial storage tanks, and recreational equipment among others.

Q4: How does the rotational molding process work at Tianyang?

A4: The rotational molding process at Tianyang involves placing plastic powder into a mold, which is then heated and rotated along two perpendicular axes. This distributes the plastic evenly along the walls of the mold, forming the desired hollow shapes as it cools down.

Q5: What is the lead time for an order from Tianyang Rotational Molding?

A5: The lead time can vary depending on the complexity and quantity

of the order. Generally, it takes several weeks from design

approval to final production. For a more accurate estimate, please

contact us with your project details.