Changzhou Yingchuang Rotomolding Equipment Co,. Ltd |

|

Verified Suppliers

|

|

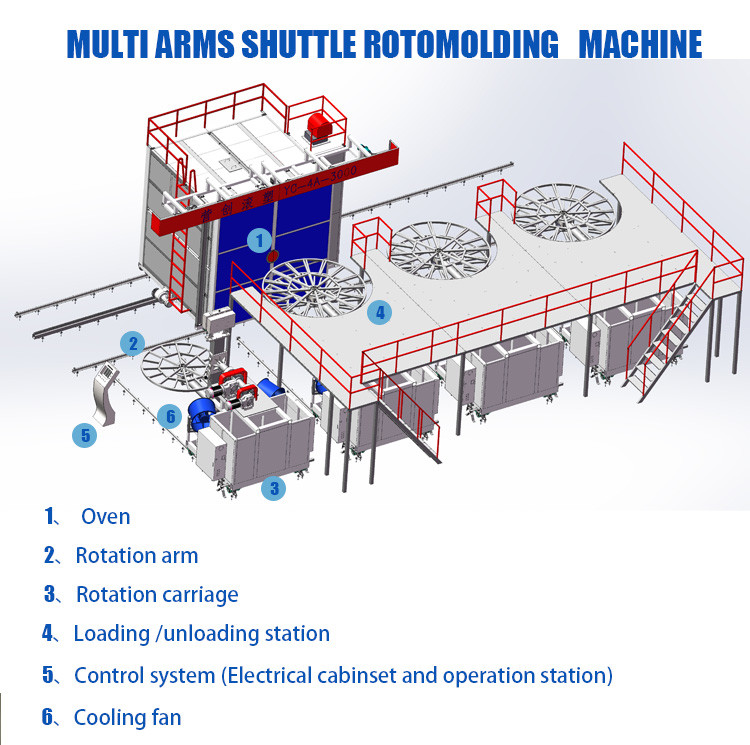

This advanced machine was designed to maximize reliability and simplicity in use. It is highly suitable for producing large volumes, even of different sizes with similar working cycles. With a sturdy construction and minimum maintenance required, this is a great choice for those who want a reliable and hassle-free production.

The machine can be equipped with up 3 or 4 arms which can change stations simultaneously and alternate in the different phases. This allows for many customizations such as a double loading/unloading station and a pre-cooling feature.

Other advantages of this advanced machine include its fully automatic compact design for a consistent quality product, its unique mechanical design for a trouble-free running and a variety of safety interlocks for a safe working environment. It is also equipped with a high efficient heating chamber, LPG/Diesel burner and blowers specially designed to work under high temperature for fuel economy.

Also, this advanced machine is easy to maintain due to its unique design. With all its features combined, this machine is an ideal choice in for high volume production.

Equipment advantages:

| Parameter | Value |

|---|---|

| Warranty | 1 Year |

| Material | PP/PE/HDPE/LLDPE |

| Applicable Industries | Manufacturing Plant |

| Power | 49KW, 62KW, 63KW, 85KW |

| Voltage | 220V/380V/440V |

| Feature | Automatic |

| Tank Volume | 2500L, 4500L, 7000L, 10000L, 14000L |

| Dimension(L*W*H) | 1700*1100*5300 |

| Equipment Type | Biaxial Rotomoulding Machine |

Many different kinds of products can be made with rotomolding technology, including water tanks, oil tanks, military boxes, lampshades, urea tanks, inspection wells, roadblocks, floats, auto parts, kayaks, boats, troughs, calf barns, and septic tanks. The results of rotomolding are both robust and lightweight, which is why it is an ideal manufacturing technology for many of these products.

Rotomolding can create products of varying sizes, from simple to highly complex. The process is very versatile, and can produce items with intricate shapes that wouldn’t be possible to create with other manufacturing techniques. This allows for the production of items that can be used in a wide range of industries and applications, from military and automotive to agriculture and home DIY.

Rotomolding is also fast, efficient and cost-effective, meaning that more manufacturers are increasingly turning to it to produce the perfect product for their clients. With rotomolding, virtually any design can be brought to life in a fraction of the time it would take with other types of manufacturing.

If you are looking for a Bi Axial Rotomoulding Machine for your business, then Yingchuang is the right choice for you. This machine is a biaxial rotational molding machine, also known as rotary moulding machine, which is designed to be used in the manufacturing industry. It is CE and ISO9001 certified and has a minimum order quantity of 1 acre/acres. The packaging details are wooden box and the delivery time is 30 working days. This machine is made of PP/PE/HDPE/LLDPE and has a dimension of 1700*1100*5300. It comes in tank volume of 2500L, 4500L, 7000L, 10000L and 14000L. It is highly efficient and automatic in nature.

The Bi Axial Rotomoulding Machine is carefully packaged in a strong, weatherproof carton or crate, with extra padding for delicate parts. The crate is then secured to a pallet for safe transit.

The machine is shipped on a flatbed truck, with the delivery location determined by the customer. The delivery driver will unload the machine and place it in the customer's designated area. The driver is not responsible for any setup or installation of the machine.

All components of the Bi Axial Rotomoulding Machine are inspected before shipping to ensure the machine is in proper working condition before it is delivered.