Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

Three Waves Guard Rail Roll Forming Machine

Saibo Science & Technology manufactures roll formers that can make different kind of road crash barrier.

Saibo Science & Technology designers, engineers, and manufactures collaborate to produce quality roll forming lines for the road crash barrier and Highway soundproof panels industry. Whether at home in China, or abroad, we provide full installation, training, and ongoing service to all of our clients.

Profile:

All of our machine profile is customized, above profile is only for your reference.

1. Coil width: 760mm

2. Thickness: 2.0-3.2mm

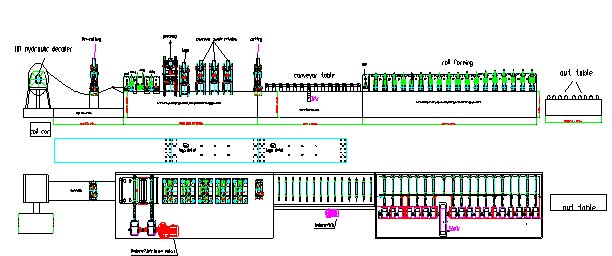

Layout:

Coil Car----De-coiling—pre-cutting----Feeding (take the sheet to the first station)-------leveling---first big punching (28 holes together)-----punching logo---- Punching two-------punching three-------punching four-------cutting-------conveyor table------guide---- roll forming- ---manual out table

Specifications:

| Item NO |

Description |

Offered specification |

| 1 | Roll Forming Machine | Guard rail

|

| 2 | Material Width | According to the profile |

| 3 | Rolling Speed | 5-12m/min |

| 4 | Rolling Thickness | 2.0-3.2 mm |

| 5 | Control System | PLC (Panasonic) as list in the note |

| 6 | Un Coiler | 10 ton hydraulic de-coiler |

| 7 | Pre-cutting | The first big punching adopt double cylinders, the other three punching adopt single cylinder |

| 8 | Leveling Station | Upper is 3 rollers, down is 4 rollers (total is 7 stations), material is 40Cr steel, HRC48-52° , 7.5kw |

| 9 | Punching | Four sets |

| 10 | Cutting mode | Hydraulic pre-cutting |

| 11 | Material Of Cutting | Cr12Mov quenching 58-62℃ |

| 12 | Hydraulic Station Power | 22kw |

| 13 | Hydraulic Pressure | 25Mpa |

| 14 | Conveyor table | 3KW, 6 meters |

| 15 | Roller Stations | 20 stations (according the final design) |

| 16 | Roller Material | GCR15, HRC58-62℃ coated with chrome |

| 17 | Shaft Material and DIA | ¢100mm, material is 45# forge steel |

| 18 | Maim Motor Power | 55kw |

| 19 | Structure Of The Stations | Cast iron |

| 20 | Tolerance | 3m+-1.5mm |

| 21 | Electric Source | 380V, 50HZ,3 phase According to customer’s require

|

| 22 | Way Of Drive | By gearbox |

| 23 | Color Of The Machine | Yellow and blue |

5. Specification of Components

(1) 10T hydraulic decoiler

(2) Pre-cutting

(3) Feeding & Leveling

(4) Punching

(5) Cutting

(7) Conveyor table

(8) Roll forming