Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

sheet metal forming equipment

About metal decking:

Saibo Science &Technology Machinery’s high efficiency deck roll forming lines produce roof, composite, and floor metal decks.The roll forming line can also be designed to create multiple profiles (metal deck panel, liner panel and roof/wall panel) which are roll formed and stacked in the same operation.

Metal deck is one of very component in PEB project, it have many different design, like YX35,YX44,YX53,YX75,YX114,YX135,YX153 (here number means the height of profile)and so on. The thickness range is from 0.6mm-2.0mm. Normal design is one machine one profile, but we can give one machine make different design, just need change the full forming section, we called its “cassette design”.

1. Specification of the material

| 1 | Suitable Material | Colored Steel plate, Galvanized steel |

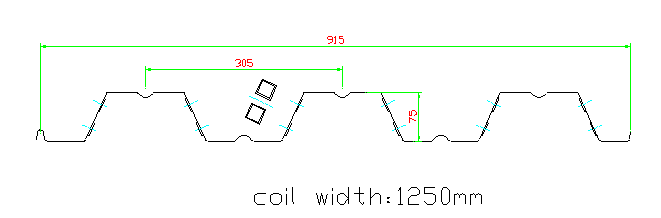

| 2 | Width of the raw material | 1250mm |

| 3 | Thickness | 0.7mm-1.2mm |

2. Machine Detailed Parameters

1

| Roll Forming Machine | YX75-305-915 |

2

| Machine structure | Wall board structure |

3

| Total power | Motor power-11kw x2 Hydraulic power-5.5kw |

4

| Roller stations | About 30 stations |

5

| Productivity | 0-15m/min |

6

| Drive system | By chain |

7

| Diameter of shaft | ¢85mm solid shaft |

8

| Voltage | 380V 50Hz 3phases (Customized) |

9

| Color Of The Machine | Yellow and blue |

10

| Container need | 40HQ container |

11

| Deliver Time | 70 days |

12

| Terms Of Payment | 30%T/T 70% pay before shipment |

3. Profile drawing

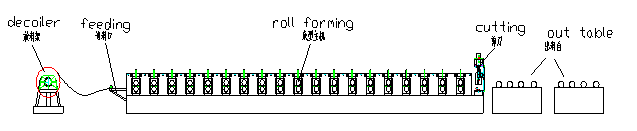

4. The Chart of Process Flow

5. Specification of Components

(1) 5T Manual Un-coiler

(2) Main Roll Forming Machine

(3) Hydraulic cutting system

(4) Computer Control Cabinet