Xiamen New KaiHang Machinery Co., Ltd |

|

Verified Suppliers

|

|

Floor deck roll forming machine, metal deck, steel deck, roofing panel, floor support, high rib

1. Description of floor tile making machine galvanized steel floor decking sheet roll forming machine

Metal roofing decks are available in a variety of types including narrow rib, intermediate rib, wide rib, and deep rib, and are used to support insulation or lightweight concrete and the waterproof membrane of a roof.

These metal roofing deck can be left exposed for open ceiling designs or manufactured with added acoustical perforations

Our automatic deck panel machine consist of decoiler, control by PLC and encoder which cut automatically at required length. Easy to operate.

We have various designs, coil width from 900-1250mm all have.

2. Technical details of galvanized steel deck panel floor tile sheet metal forming machine

| Machine Specifications | |

| Weight | About:38000kgs |

| Size | About :20mx2.2mx1.3m(length x width x height) |

| Color | Main color: blue and orange |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 0.8-1.25mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 38 |

| Diameter of forming rollers shafts8 | 95mm solidt |

| Roll Forming Speed | 20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 2*18.5kw |

| Hydraulic unit motor power: 7.5kw | |

| Electric voltage | According to customer’s requirement |

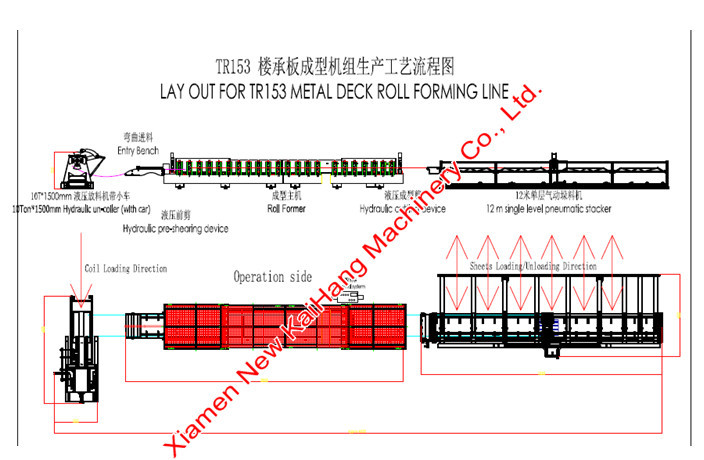

3. Main components of roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

| Hydraulic pre cutting system | Optional |

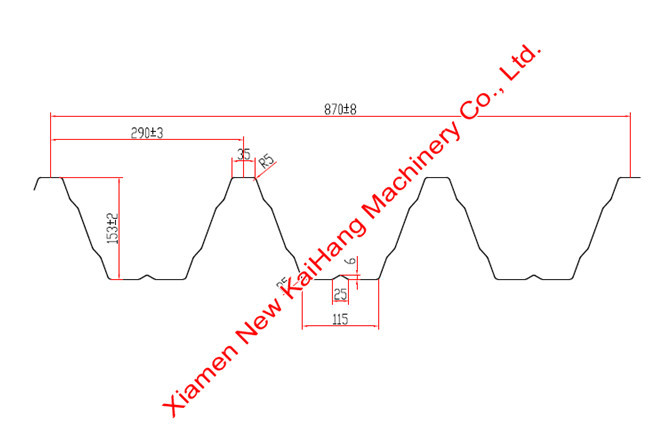

4. Profile drawings