Xiamen New KaiHang Machinery Co., Ltd |

|

Verified Suppliers

|

|

Steel Z purlin roll forming machine, pre punching/ post cutting, size change by manual spacers

Quick Detail:

Application:

C purlin roll forming machine is equipment that produces C shaped steel channels continuously out of galvanized or cold rolled steel strips from feeding, punching for holes, bending and cutting.

Z purlin roll forming machine works in the same principle as a C purlin roll forming machine does for producing steel purlins for metal building systems, only the purlins’ shapes make difference.

Z steel purlins can be used for a variety of applications, but 90% for steel structural building system, and 10% for other usages (some people use z steel purlins as the supporting clip inside sandwich panels, while some others put z steel purlins on a samples racks etc).

Machine list:

Description/Technical Parameter details of complete line:

Un-powered; Load capacity= MAX.5Ton

Hydraulic system to expand coil inner hole, Pump motor: 3KW

Coil inner–diameter=510+/-30mm

Coil Width= MAX.600mm

Mandrel rotation: Draft type

Pre-Level Device with 4 over 3 shafts to remove the Coil-set

Share the same motor with the roll former

Share in the same hydraulic group with post cut

To punch below holes

Single slotted or round holes on web

Double slotted or round holes on web

Single slotted or round holes on flange each side

| Suitable roll forming material | Color steel sheet or galvanized steel sheet |

| Thickness | 1.5-3.0mm |

| Carriage Frame design | wall-plate-frame-type |

| Roll forming stages | 13 stages |

| Roller material | GCr15, heat treatment, hard chrome coated |

| Shafts Diameter | Φ75mm |

| Main motor power | 15Kw*2 |

| Production speed | 12m/min |

| Electric Voltage Standard | 380V/50Hz/3PH or as request |

| Major Color of Machine Painted | RAL 5015(Blue) or as request |

Hydraulic group: 11KW

Stop to cut design

There is not waste after cut-off

Cutting material: Cr12, heat treatment

Control the quantity & cutting length automatically

Combined with: Siemens brand PLC and Touch Screen

Schneider brand Inverter, Omron encoder, etc

Cut-to-length tolerance≤±1mm

Control voltage 24V

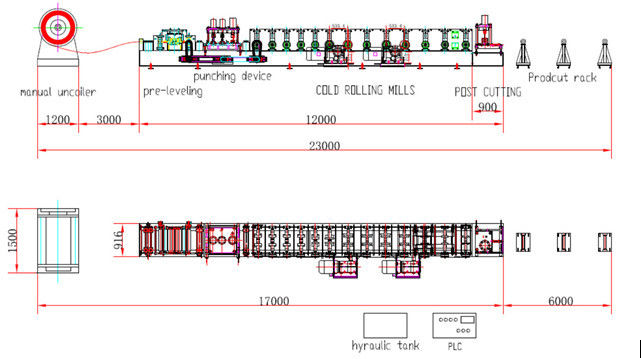

Profile Drawing/Layout/Equipment reference pictures: