Xiamen New KaiHang Machinery Co., Ltd |

|

Verified Suppliers

|

|

Australian roller shutter door roll forming machine, roller shutter door roll forming machine

Quick Detail:

Application:

This roller shutter door roll forming machine makes corrugated panels, not slats, to joint each other horizontally for manufacturing rolling shutter doors.

A roller shutter door panel roll forming machine has much similar function as a steel rolling shutter door slat roll forming machine does, and both roll forming machines have been designed for producing roller shutter doors.

Machine list:

Description/Technical Parameter details of complete line:

Hydraulic system to expand coil inner hole, Pump motor: 3KW

Coil Inner-diameter= 510±30mm

Load Capacity: Max. 5 Tons

Coil Width Max. 1250mm

Taper wedge expand type

Driving motor to turn the coil, 3KW

To cut off the end of the final piece of sheets only

Working thickness: max. 0.8mm

| Suitable roll forming material | Good quality pre-painted coil |

| Thickness | 0.4mm-0.6mm |

| Coil input width | 1220mm |

| Carriage Frame design | Wall-plate-frame-design, Plate thickness 18mm |

| Roll forming stages | 28 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ75mm |

| Main motor power | 11Kw driven motor |

| Rolling speed of roll former | 15-20m/min |

| Hydraulic group power | 5.5 Kw |

| Material of cutting blade | Cr12, hear treatment |

| Electric Voltage Standard | 380V/50Hz/3PH or as requirements |

| Major Color of Machine Painted | RAL 5015(Blue) or as requirements |

Siemens brand PLC and touch screen, Schneider/ Shihlin/ Delta brand Inverter, Omron encoder

Cut-to-length tolerance≤±1mm

Control Voltage 24V

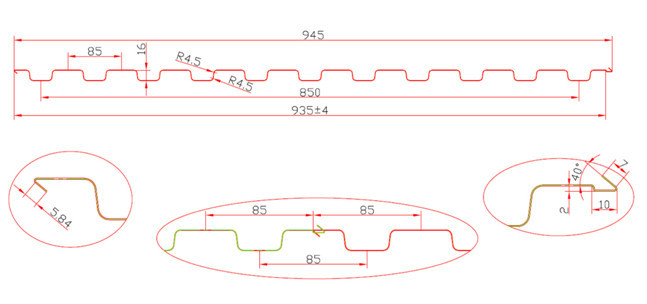

Profile Drawing/Layout/Equipment reference pictures: