Jiangsu Acemien Machinery Co., Ltd. |

Parallel Twin Screw Extruder General Introduction and Application:

The screw and barrel adopt a "building block" structure, which has good interchangeability. If the one of them is broken, replace the other. If there is no defect in the conical twin screw, the entire one must be replaced. It can be used in any combination according to the different material processing technology; the barrel body is made of nitrided steel and bimetal materials, which are wear-resistant, corrosion resistance and extended service life.

Meantime, nitrided steel and high-speed steel are selected for the threaded components, and the unique processing technology is used to ensure the normal teeth of the threaded working section surface clearance and good self-cleaning, on the other hand the specially designed connection method and transmission device enhance the strength of the threaded element and the mandrel. The above measures realize the uniform dispersion of the material, the good mixing and plasticizing, and the material stagnation, and finally the purpose of short residence time and high conveying efficiency

The Application for Plastic PE PP Pellet From Plastic Waste

Introduction to PE recycled plastics

Polyethylene (PE) --- milky white color translucent when uncolored,feels slippery when touched by hand, soft and tough, slightly stretchable, generally low density Polyethylene is softer and more transparent, and high-density polyethylene is harder. It is mainly used for lamination film, shopping bags, water pipes, and oil drums.

In daily life, recycled particles can be used to make all kinds of plastic bags, barrels, basins, toys, furniture, stationery and other household appliances and various plastic products.

In the clothing industry: recycled granule can be used to make clothing, ties, buttons, zippers.

In terms of building materials: recycled pellet can be used to make various building components, building tools, plastic doors and windows, stucco buckets.

Agriculture: recycled pellet can be used to make agricultural films, pumping pipes, agricultural machinery, fertilizer packaging bags, cement packaging bags.

Machinery industry: Using special formulation, recycled granules can be used to manufacture machine parts: various forms of bearings, gears, cams, different wheels, sealing rings, various blades, various water pump impellers.

In the chemical industry: Regenerated granule can be used as reactors, pipes, containers, pumps, valves, etc., and used in chemical production sites that solve corrosion and wear.

In addition, recycled particles are also widely used in the electrical and telecommunications industries.

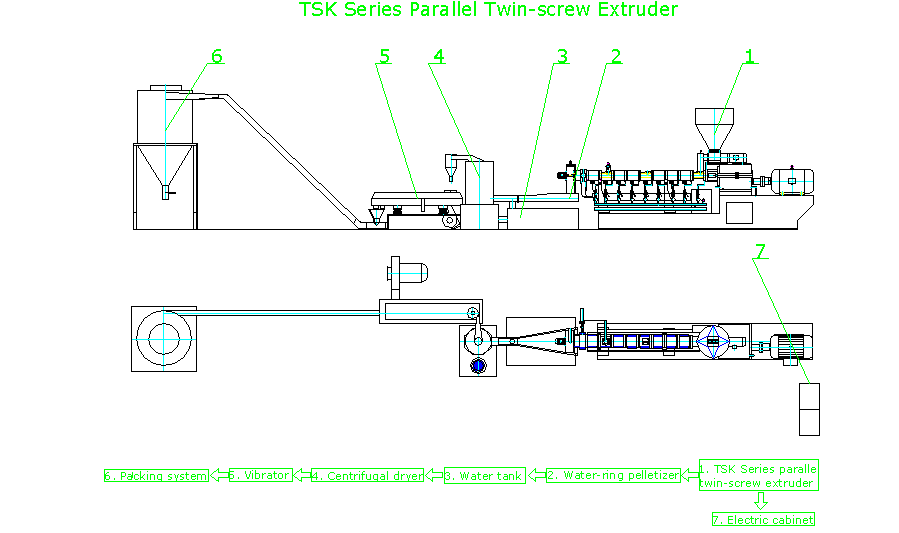

Equipment list

| No. | Machine | Qty. | Remarks |

| 1 | TSK65 Extruder & Electric cabinet | 1set | 90KW |

| 2 | Die face mould | 1set | 13 holes, 3mm diameter |

| 3 | Cooling water tank | 1set | |

| 4 | Cyclone dryer | 1set | |

| 5 | Pellet Cutter | 1set | |

| 6 | Vibrating sieve | 1set | |

| 7 | Loading blower | 1set | |

| 8 | Silo storage and packing | 1set | 1000L |

FAQ

Q1:What's your warranty policy?

A1:We will guarantee the machine for 12 months since the date of

shipment(which means leaving from Seller's factory) or the Seller

will guarantee the machine for 12 months since the date of starting

installation and adjustment, whichever comes first.

Q2:What's your minimum order quantity?

A2: Min order quantity:1 set or by negotiate with each other.

Q3:What package do you use for the product?

A3: covered with plastic film, then packed in wooden box.

Q4:Do you have technical instruction if I buy your product?

A4:Please read the user manual carefully for your reference, we

have detail instruction on it. If your problems still can not be

solved, welcome to contact us for help.

Q5:What is your overseas service?

A5:We will provide high quality overseas service ,our technician

will be able to provide you with technical support ,for you

personally to overseas assembly and test equipment.

Q6:Will you conduct training for our staff here?

A6:Yes, we will provide technology support to factory technology,

training for the relative person.

Q7:What are your terms of payment?

A7:We accept T/T, L/C.

Q8:What's your contact way?

A8:Kevin +86 138 6226 3862

Q9:I am very satisfied after I read your FAQ, how can I start to

purchase my order?

A9:Please click the "send" at the bottom of this page or contact

our sales on Trade Manage online.