Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

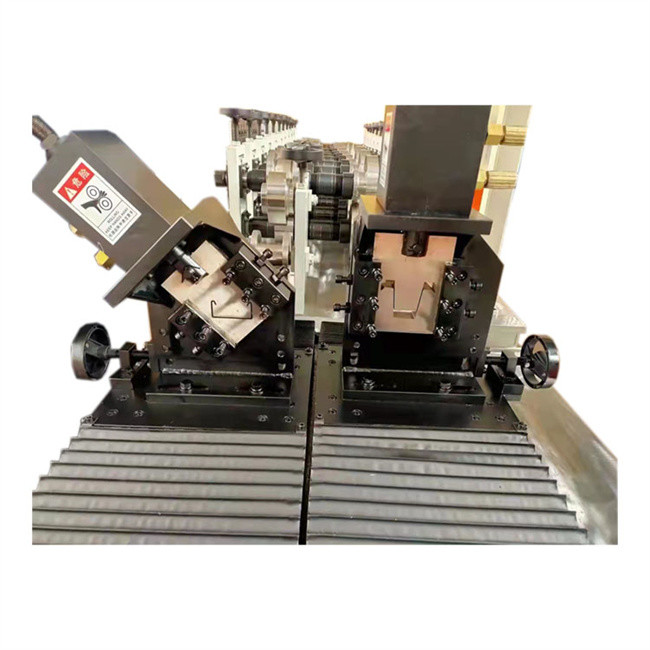

High speed metal light steel keel stud and track machine For Drywall

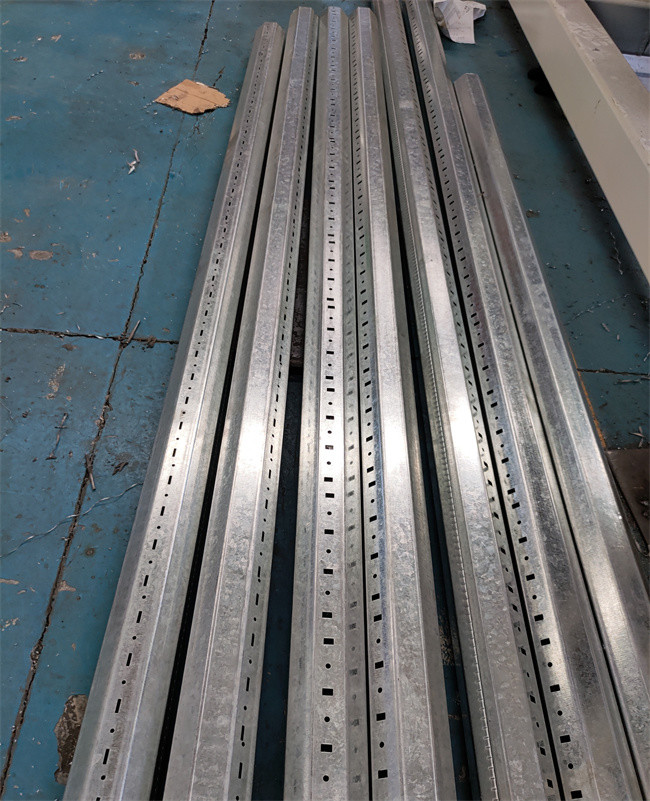

1. Description Of Stud And Track Roll Forming Machine

The light steel keel sheet has two types:Ceiling channel and drywall channel,They are made by this machine. Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages.They mainly match to paperbacked plasterboard and other goods,also the other plates such as GRC, FT and so on.They are widely used in construction of hotels, airport terminal buildings, stations, playgrounds, etc.This machine is produces light steel keel, the cutting adopts non stop cutting system,it has fast speed, the ordinary speed is 40M/min, the maximum speed can reach 100M/min, which greatly improves the production efficiency.

If you have requirements for production speed, power, voltage and brand, please explain in advance.

2. Technical Details Of Stud And Track Roll Forming Machine

| Machine Specifications | |

| Weight | About 2.5tons |

| Size | About 5M x 0.8Mx1.2M(length x width x height) |

| Color | Main color: Red or as your requirements |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | GI GL Aluminum |

| Thickness | 0.8-1.5mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

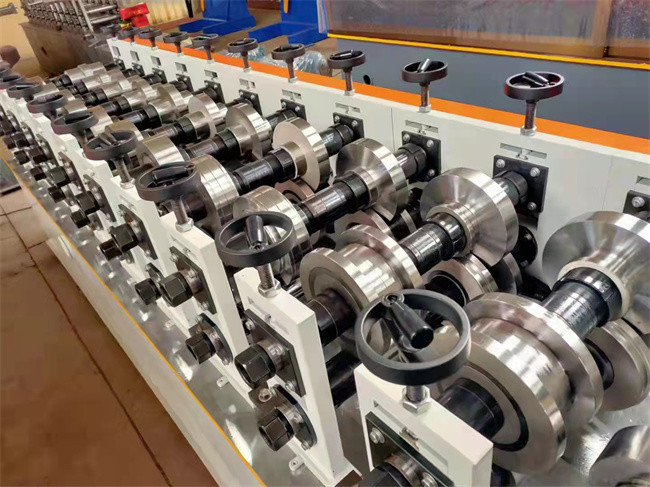

| Quantity of forming rollers stations | 12 stations |

| Diameter of forming rollers shafts | 50mm |

| Roll Forming Speed | 40m/min |

| Forming rollers material | 45# steel, coated with chromed treatment |

| Cutter material | Cr12MOV, with quenched treatment |

| Controlling system | PLC control |

| Electric Power requirement | Main motor power: 5.5kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

3. Main Components Of Stud And Track Roll Forming Machine

| Manual Decoiler | 1 Set |

| Feeding Table | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Production Flows Of Stud And Track Roll Forming Machine

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages Of Our Metal Stud And Track Roll Forming Machine

· More than 10 designers with more than 10 years experience

· We have completed production system. And more than 20 sets of CNC machines which can support lots of machine.

· Our machine's warranty period is 12 months and and we supply the technical support for the whole life of the equipment.

· Our workshop area of 25,000 square meters

· We more carefully to deal with the details. our rollers and shafts, we process 3 times.

6. Application Of The Metal Stud And Track Roll Forming Machine

This machine is widely used in the production of the metal roof sheets and wall panel. our machines are exported to many countries: Rwanda, Thailand, Philippines, Dubai, USA, South Africa, Peru, Russia, Saudi Arabia, Malaysia, Indonesia, etc.

7. Product photos Stud And Track Roll Forming Machine

8. FAQ

Q: How to visit our company:

A: 1.Fly to Beijing airport: By high speed train From Beijing Nan

to Cangzhou Xi (1 hour),then we can pick up you.

2.Fly to Shanghai Airport: By high speed train From Shanghai

Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing

airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1

hour),then we can pick up you.

Q. What is your payment terms?

A.1 : We accept 30% T/T as deposit and 70% T/T as balance before

shipping.

2 : We accept 100% L/C at sight

3: We accept Western Union payments.

4 : Other payment terms you want to pay, please let me

know and i will check and reply you.