Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

Hydraulic Cut Downspout Roll Forming Machine CNC Control Energy Saving And Security

1. Technical details of downspout roll forming machine:

| Dimension(L*W*H) | 15000mm*1500mm*1500mm |

| Base | 300H steel |

| Diameter of shaft | 70mm |

| Roller material | 45# steel or hard chromium plating |

| Cutting type | Hydraulic cutting type |

| Cutting blade | Cr12 |

| Main motor Power(Kw) | 8.0KW |

| Weight | 3-4t |

| Color | As your request |

| Material thickness | 0.3-0.7mm or As your request |

| Material width | 330mm or As your request |

| Transmission type | Chain transmission+deceleration motor |

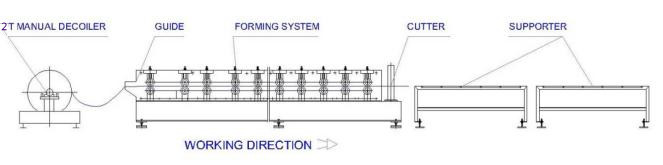

2. Production Flows of downspout roll forming machine

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

3. Main components of downspout roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4.Description of downspout roll forming machine:

Metal downspout is made by using the color steel or GGPI coils roll-pressing and end-closing, then use the special equipment hit-to-bend and necking.

Metal drainage system has the excellent weather fastness. It has the advantages such as simple design, easy installation, safe and durable, elegant.

It is widely used in the modern villas and multiple raises buildings.

JCX Factory is producing the high quality downspout roll forming machines and export to India,Uzbekistan, Russia, Bangladesh, Vietnam, Turkey, etc.

5. Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 1.5 years maintenance and whole life technical support

6. Application

.

.

7. Product photo

8. FAQ

1. Does one machine can only produce one style panel profile?

Not exactly.For some making machine. It can produce more kinds of

panels by change their rollers.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled

technicians available across the world.We need your machines

running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to

Cangzhou Xi (1 hour), then we can

pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai

Hongqiao to Cangzhou Xi(4.5 hours),

then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12 months,if the broken parts

can't repair,we can send the new parts replace the broken parts

freely,but you need pay the express cost yourself.if after warranty

period,we can through negotiation for to solve the problems,and we

supply the technical support for the whole life of the

equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich

experience in transport.

6..Why your price is higher than others?

As we persist on that each factory should put quality at the first

place. We spend time and money

on developing how to make machines much more automatic, accurate

and high quality.

We can make sure that our machine could use more than 10 years

without any problem. We can provide 18 months free quality

assurance.

7.How long the machine could be made?

Normally speaking, welded pipe making machine could be made without

45 working days.

If you need machines in a hurry, we can make it for you less than a

months.

Welcome to contact with us!