KSQ Technologies (Beijing) Co. Ltd |

|

Verified Suppliers

|

|

IADC517/537 Tricone Pilot Reamer Diamond PDC bit Hole Opener For Oil Rigs

Introduction

PDC or "PAX" core bits utilise large cylindrical shaped cutters

that consist of a layer of micron-sized synthetic diamond particles

mounted onto a tungsten-carbide backing substrate (PDC =

polycrystalline diamond compact).

The technology was originally developed for oil drilling bits. PDC

core bits have proved to be exceptionally cost effective for

geotechnical drilling.

PDC core bits have extremely fast penetration rates and a very long

working life. The cutters are extremely tough and can core

formations such as hard limestones with occasional bands of harder

rock such as ironstone.

The cutting action is extremely aggressive and a large volume of

cuttings are produced requiring good volumes of flush to clear the

hole and prevent blocking.

Recommended for coring soft to medium hard formations, with water,

air, mud or foam as the flushing medium. Ideal for air flush

applications where a high rate of production is required.

The size, number and layout of the cutters can be varied to suit

the rock hardness, abrasivity and other details of the application

PDC drill bit used to penetrate the degassing hole, drain hole, and grouting hole of coal mine, water canservancy and hydropower, road construction, bridge and building.

Description of PDC drill bit

Different types of PDC drill bit

Specifications of PDC reaming bits

| Roller cone bit(IADC) | Roller cone(m/h) | Formation hardness | Formation | Rock type | Compress strength | |

| WEM | OBM | |||||

| 111/124 | 15-30 | 18-33 | very soft | soft formation with sticky layer and low compressive strength | Clay, slits, sands | <25MPa |

| 116/137 437 | 9-15 | 18-33 | soft | soft formation with low compressive strength and high drill ability | Clay stone, marl, lignite sandstone, tuff | 25-50MPa |

| 126/139 517/527 | 4.5-9 | 6-12 | medium soft | soft to medium formation with low compressive strength and small abrasive layers | Clay stone, marl, lignite, tuff sandstone, silts, anhydrites | 50-75MPa |

| 211/217 517/537 | 2.5-6 | 3-6 | medium | medium to hard formation with high compressive strength and small abrasive layers | Mudstone, limestone anhydrites sandstone(calcareous) | 75-100MPa |

| 211/236 537/617 | 1.5-2.5 | 1.5-3 | medium hard | hard and dence formation with very high compressive strength but non abrasive | Limestone, anhydrites dolomite | 100-120MPa |

| 311/347 627/637 | 1-1.5 | 1-1.5 | hard | hard and dence formation with very high compressive strength and some abrasive layers | shale(calcareous), sandstone (siliceous), siltstone | 100-200MPa |

| 637/737/837 | 1 | 1 | very hard | extremely hard and abrasive formation | Quartzite, rock | >200MPa |

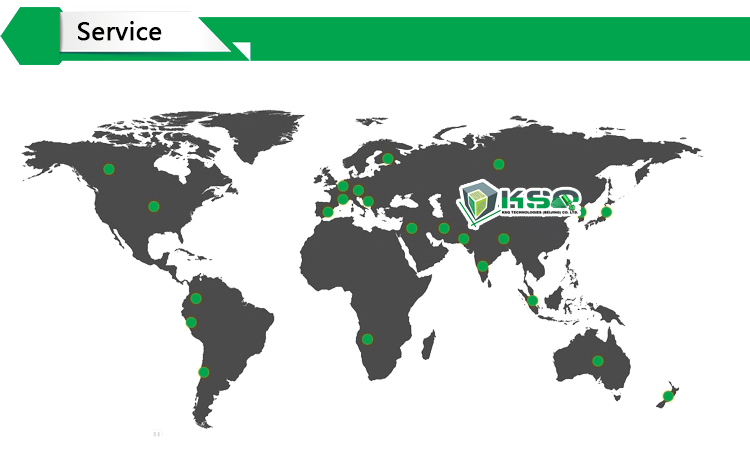

About us

MIROC® Rock Drilling Tools are Rock Drilling Tools Brand by KSQ Tecnologies (Beijing) Co. Ltd.

KSQ Technologies (Beijing) Co. Ltd. provides exceptional technical

know-how in development, production, and application. The company

has adopted advanced manufacturing processes to ensure high quality

steels and tungsten carbide inserts for its rock drilling

accessories. Its personnel understand clients’ drilling needs, and

have the service skills to recommend the right drilling tools for

the job. Its experienced product developers can also create custom

tools. Furthermore, the company’s development team introduces

innovative products each year – tools that are rigorously tested in

the field and proven

to perform beyond industry expectations.

MIROC® Rock Drilling and Ground Support Tools include:

Integral Rods

Plug Hole Rods

Tapered Drilling Tools

Extension Drilling Tools

Drifting and Tunneling Tools

Reaming Tools

Shank Rods

Shank Adapters (Striking Bars)

Down-the-hole (DTH) Bits

Down-the-hole (DTH) Hammers