Xiangjing (Shanghai) M&E Technology Co., Ltd |

|

UNIVERSAL ROBOT ACCESSORIES ATI MC-10 MANUAL TOOL CHANGER

Introduction

ATI Industrial Automation's MC-10 Manual Tool Changer provides a cost-effective solution for quickly changing tools by hand.

Its compact, yet robust design, is optimized for collaborative robot applications and is a perfect fit for all UR robot models.

Features and Benefits

The MC-10 Manual Tool Changer's ergonomic grip, locking mechanism ensures a secure attachment of the tool and easy manual operation with tactile feedback. This Manual Tool Changer can carry payloads of up to 10 kg (22 lbs) and includes multiple fail-safe features that resist vibration and prevent loosening. The MC-10 has integrated air pass-through connections and options to connect electrical utilities if needed.

Dimensions:

Master Side Dimensions:

Height: 43.5 mm (1.71 in)

Diameter: 53.3 mm (2.09 in)

Weight: 0.272 kg (0.6 lb)

Tool Side Dimensions:

Height: 9.5 mm (0.37 in)

Diameter: 53.3 mm (2.09 in)

Weight: 0.0907 kg (0.2 lb)

How does it work

The MC-10 Manual Tool Changer utilizes a manually-actuated twist-collar locking mechanism for coupling end-effectors to a UR robot arm. The user brings the Master (robot) and Tool (end-effector) sides together and applies a twisting motion until feeling a "click." This tactile feedback, along with the alignment of visual icons, indicates successful locking.

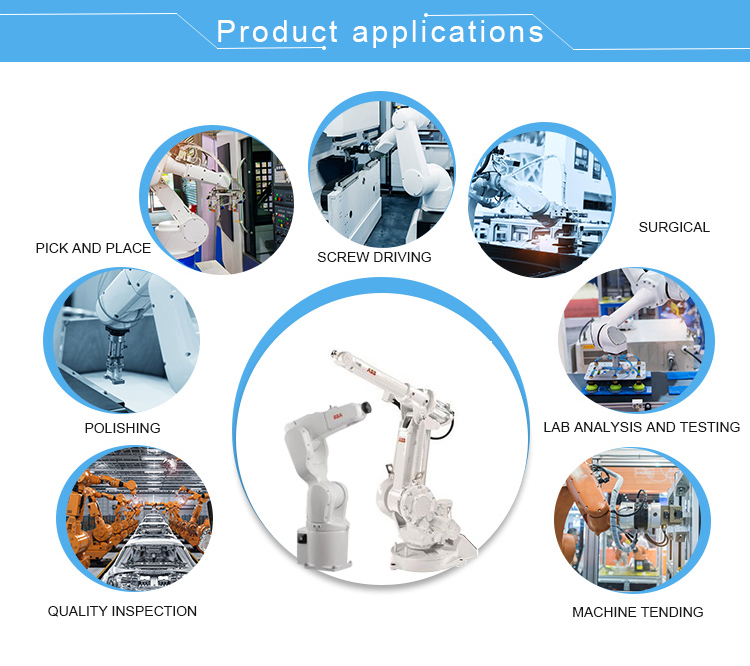

Applications

• Screw Driving

• Packing and Palletizing

• Assembly

• Polishing

• Gluing, Dispensing and Welding

• Pick and Place

• CNC

• Lab Analysis and Testing