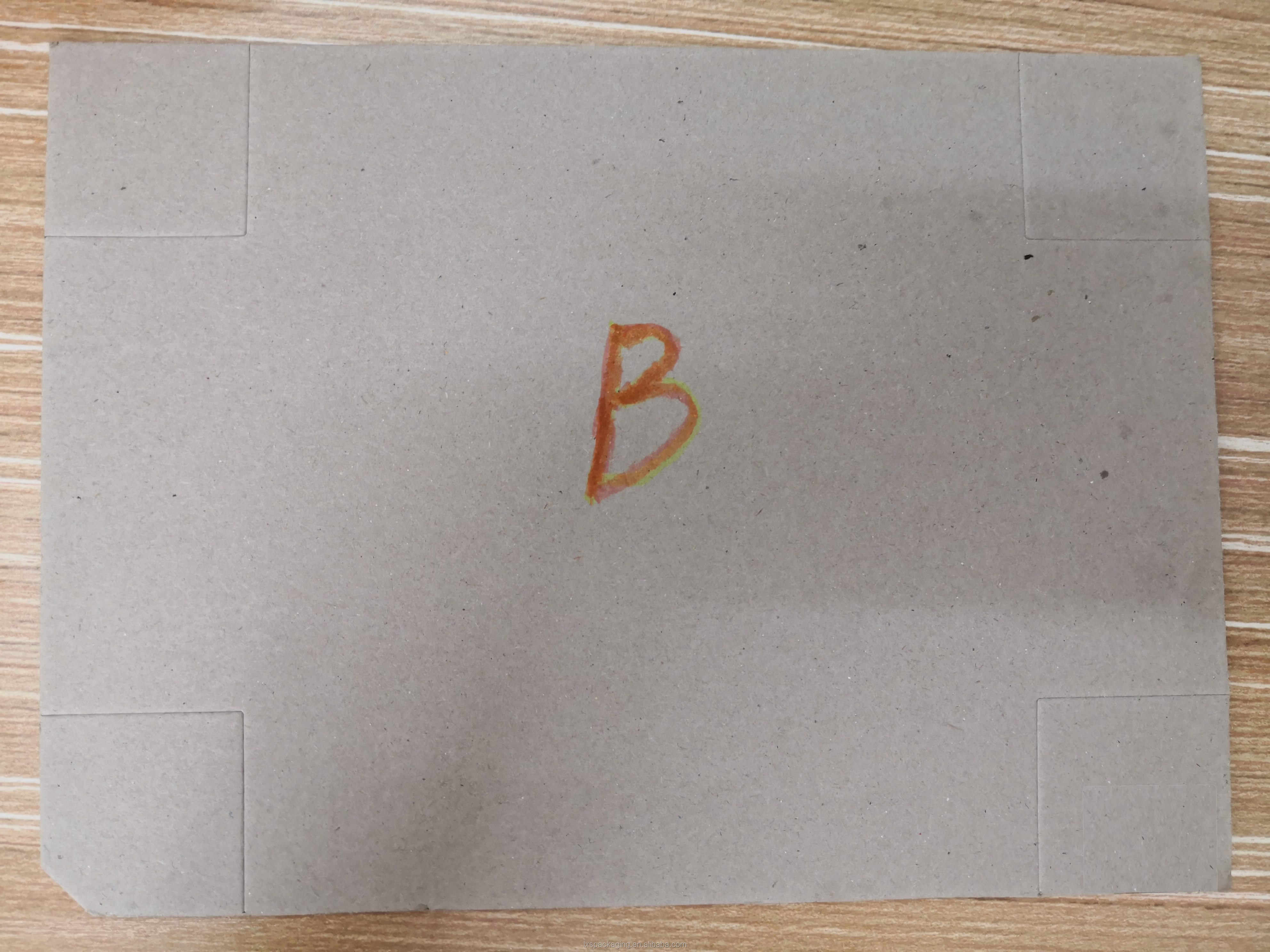

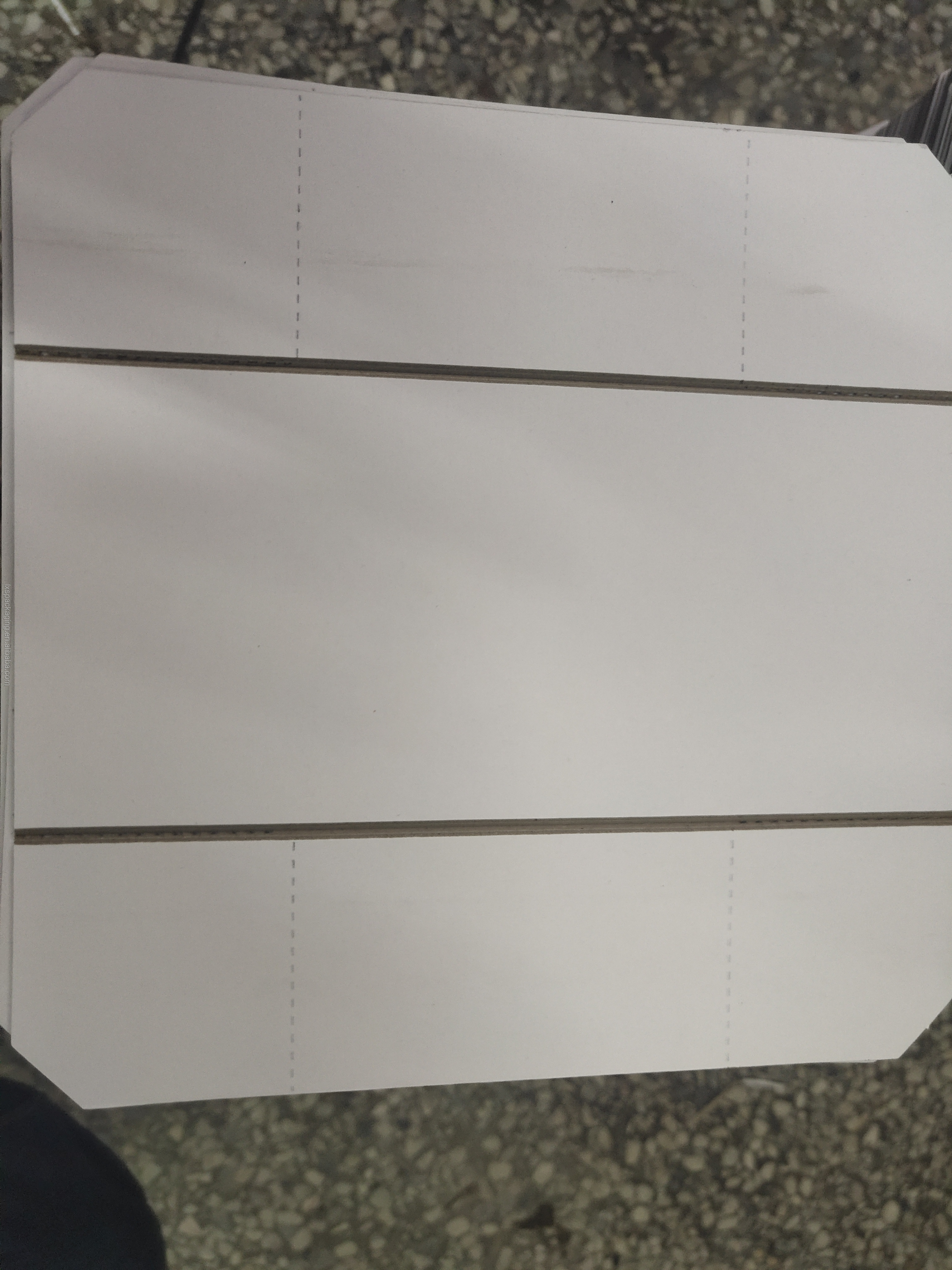

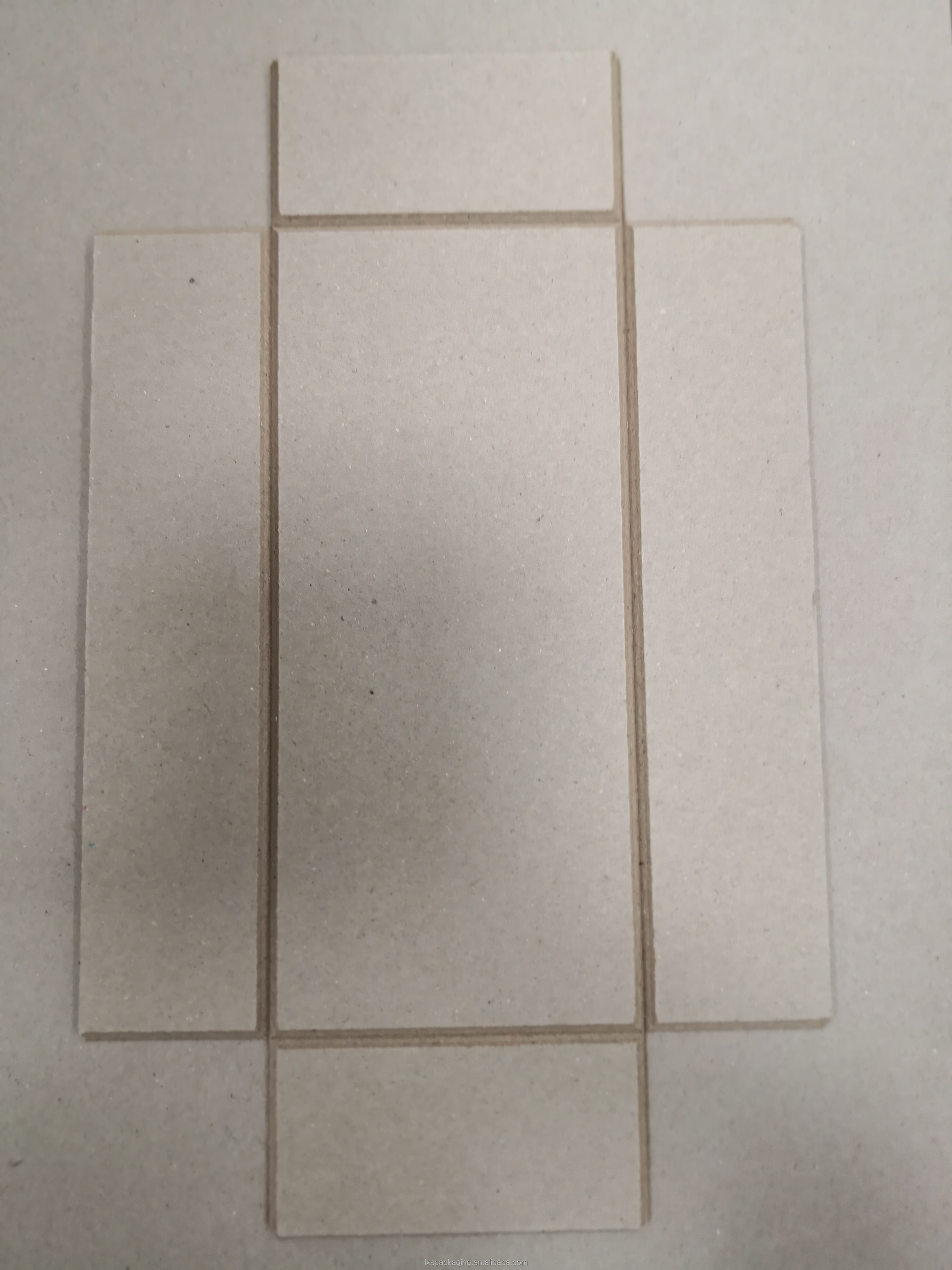

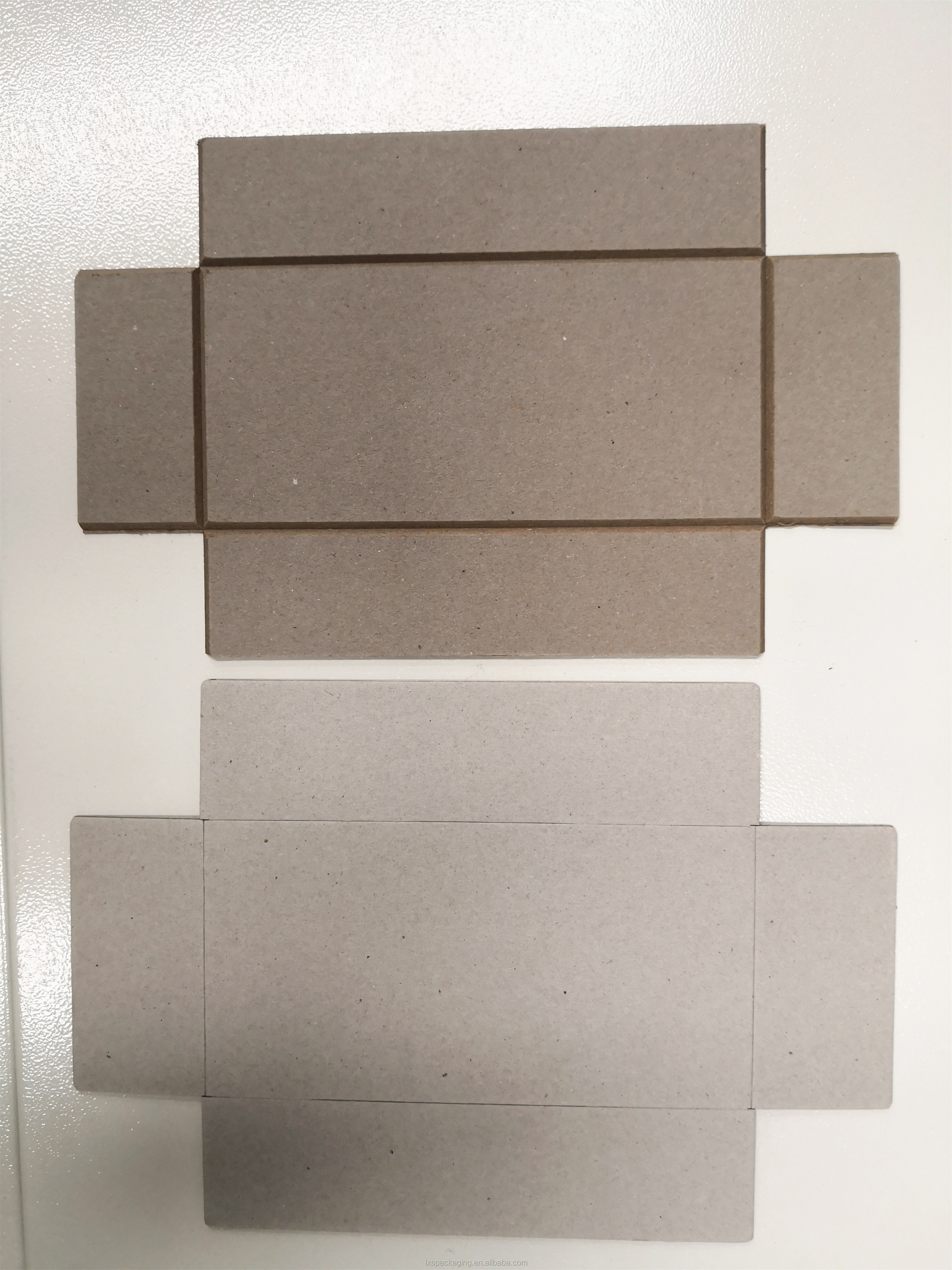

LS-1200B Automatic cardboard grooving machine is using for cardboard V shape slots grooving. It can groove at 80-140 degree V slots. It can groove 8 slot at a time (Depend on cardboard size). Working speed is 40m/min, around 100-200 pcs/min.

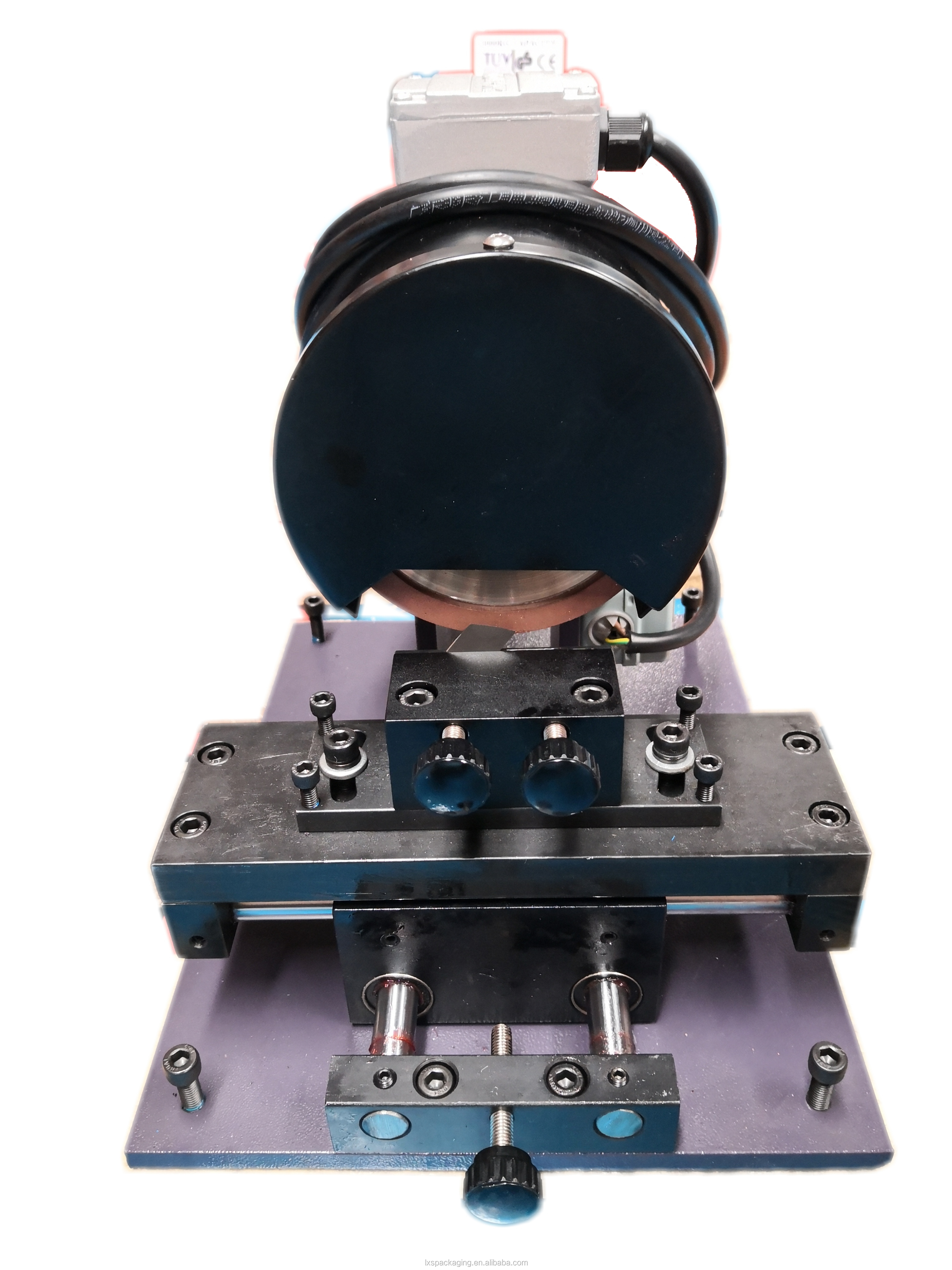

LS-1200B has applied belt feeding syatem and double alligning system to ensure the constant and accurate cardboard feeding to grooving area. In the grooving area, it applies big roller which diameter is 60cm and pressing belt to convey card board pass the grooving blade. After finished, the conveyor will convey grooved cardboard to the front side, corner waste and slots waste will be feeding to the back side.

This roller grooving machine has start from 2012, Now it is popular in the packing industries. It is an ideal equipment for cardboard, MDF board and thin paper grooving.

Price vary with raw material cost, please contact our sales for lastest prices.