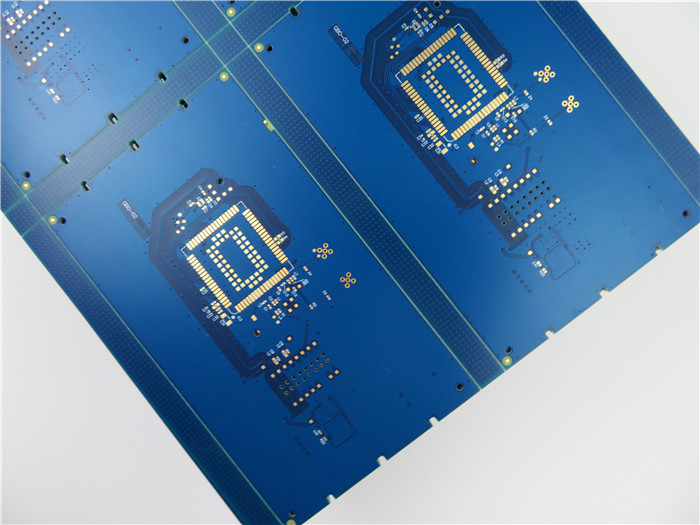

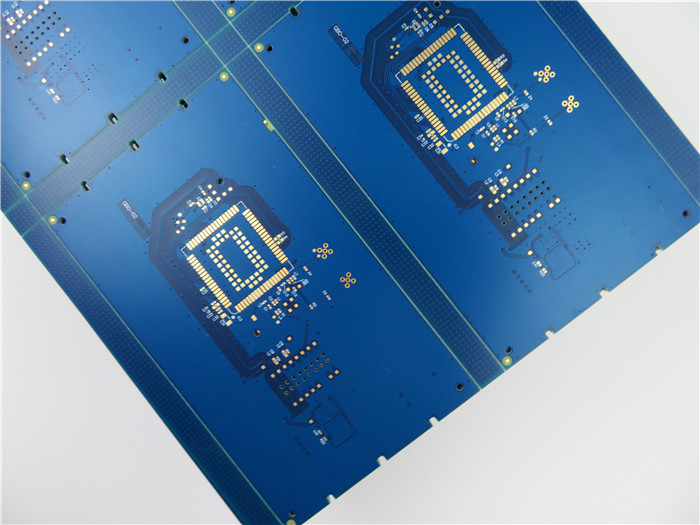

Immersion Gold PCB ENIG Circuit Board Soft Gold PCB Chemical Gold

Circuits for Intercom System

1.1 General description

This is a type of matt blue PCB built on FR-4 substrate with Tg

130°C for the application of intercom system. It's a 4 layer board

at 1.40 mm thick with 1oz outer layer and half ounce inner layer.

White silkscreen over matt blue solder mask on both top and bottom

side. Surface finish is immersion gold on pads. The base material

is used from ITEQ IT-158, entire board supplying 4 up per panel.

They're fabricated per IPC 6012 Class 2 using supplied Gerber data.

Each 25 panels are packed for shipment.

1.2 Features and benifits

It’s suitable for handheld and consumer applications;

RoHS compliant and suitable for thermal reliability needs;

Excellent surface planarity, helpful for PCBs with BGA packages to

reduce failure rate during assembly and soldering;

SMT process is resistant to reflow soldering, resistant to rework;

Experienced sales persons and skilled customer services;

No minimum order quantity and low cost sample;

Focus on low to medium volume production;

Delivery on time: >98%

Customer complaint rate: <1%

No quality complaint is meant to save money;

1.3 Applications

Intercom

Spread Spectrum

Phone Signal Booster

Vehicle Tracking Devices

AC DC Transformer

1.4 Parameter and data sheet

| PCB SIZE | 285 x 195=4 PCS |

| BOARD TYPE | Multilayer PCB |

| Number of Layers | 4 layers |

| Surface Mount Components | YES |

| Through Hole Components | YES |

| LAYER STACKUP | copper ------- 17.8um(0.5oz)+plate TOP layer |

| Prepreg 1 x 1080 + 1 x 2116 |

| copper ------- 17.8um(0.5oz) MidLayer 1 |

| FR-4 1.0mm |

| copper ------- 17.8um(0.5oz) MidLayer 2 |

| Prepreg 1 x 1080 + 1 x 2116 |

| copper ------- 17.8um(0.5oz)+plate BOT layer |

| TECHNOLOGY | |

| Minimum Trace and Space: | 5.9 mil / 5.8 mil |

| Minimum / Maximum Holes: | 0.775 mm / 2.0 mm |

| Number of Different Holes: | 4 |

| Number of Drill Holes: | 217 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 0 |

| Impedance Control: | no |

| Number of Gold finger: | 0 |

| BOARD MATERIAL | |

| Glass Epoxy: | FR-4 Tg130℃, er<5.4.IT-158, ITEQ Supplied |

| Final foil external: | 1 oz |

| Final foil internal: | 0.5 oz |

| Final height of PCB: | 1.4 mm ±0.14 |

| PLATING AND COATING | |

| Surface Finish | Immersion gold (22.1% ) 0.1µm over 3µm nickel |

| Solder Mask Apply To: | TOP and Bottom, 12micron Minimum |

| Solder Mask Color: | Matt Blue, KSM-6189BLM1 |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing, v-groove |

| MARKING | |

| Side of Component Legend | TOP and Bottom. |

| Colour of Component Legend | White, IJR-4000 MW300, Taiyo brand |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | Plated through hole(PTH), minimum size 0.78mm. |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" |

| Board plating: | 0.0029" |

| Drill tolerance: | 0.002" |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

1.5 Advantages of PCB Boards with Electroless Nickel and Immersion

Gold

(1) Flat Surface

The most important feature is that the surface of all pads is

perfectly flat, corresponding to the underlying copper surface,

with all pad and track edges covered by nickel/gold.

(2) Low Defect Rate

An important reason for choosing immersion gold surface protection

is a highly reduced failure rate during assembly and soldering

compared with solder-coated and hot-air leveled boards. It is

especially true of fine line boards with a component pitch of 0.5

mm (20 mils) or less.

(3) Solderability

Solderability is high but the soldering time is a little longer

(about 5 seconds.) compared with wave soldering (3seconds.)

(4) Stressing of Boards

Because the PCB boards have not been exposed to high temperatures,

no stressing of the plated-through holes will occur. So the

low-temperature processes is that no delamination of the laminate

will take place.

(5) Dimensional Stability

Since the boards are not subjected to temperatures above 90° C

(194° F) during manufacture, the dimensional stability is high.

This is of great importance when screen-printing solder paste on

fine-line SMT boards because a better fit between the stencil and

the pattern is achieved than in the case of solder coated and

hot-air leveled boards.

(6) Contamination of Board Surface

Since there is no flux residue on the board surface as there is

with solder-coated and hot-air leveled boards, surface

contamination is considerably lower. Measurements indicate a 4.5 μg

NaCl/sq.cm (29 μg NaCl/sq.in.) contamination of solder coated and

hot-air leveled boards and just 1.5 μg NaCl/sq.cm (9.6 μg

NaCl/sq.in.) contamination of nickel/gold boards.

(7) Fiducials

Fiducials, the optical targets, achieve a better definition because

of the thin nickel/gold layer.

(8) Shelf Life

The shelf life is reported to be a minimum of one year when

vacuum-packed.

(9) Keyboard Contacts

It is expedient to execute on-board contacts for keyboards with the

same nickel/gold coating as on the SMT pads so that a carbon

printing can be avoided. The carbon contacts often show a

resistance of 100 to 200 ohms, and also a fairly high degree of

instability.