ZHENGZHOU SHINE ABRASIVES CO.,LTD |

|

Verified Suppliers

|

|

9A3 Resin Bond Diamond Wheels 175mm For Carbide Milling Cutters Grinding

Shine Abrasives 9A3 Resin bond double side diamond cup wheel use for manufacturing and resharpening of tungsten carbide cutters

eg-finger joint cutter, molum and male-female cutters, reamer's in wood working industries and CNC machine industries.

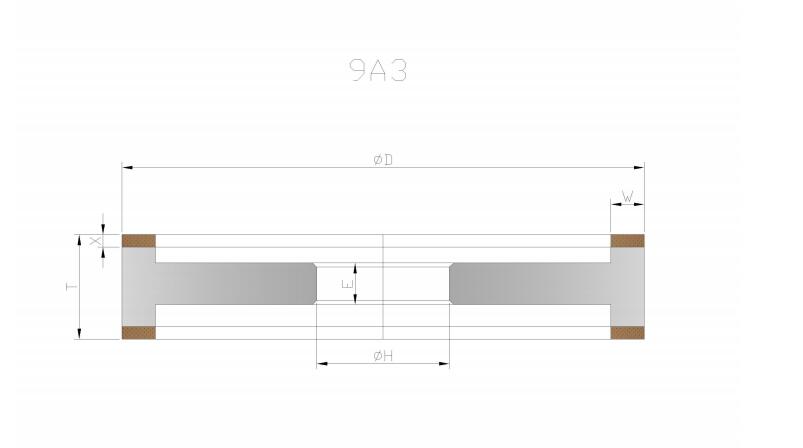

The drawing of Shine Abrasives 9A3 Resin Bond Diamond Wheels 175mm For Carbide Milling Cutters Grinding

Specifications of Shine Abrasives 9A3 Resin Bond Diamond Wheels 175mm For Carbide Milling Cutters Grinding

| Abrasive Material:Diamond | Bond Type:Resin |

| Diamond Rim Size:6x34mm | Diamond Grit:150 grit, |

| Concentration:125% | Wheel Diameter: 175mm |

| Wheel Thickness:25mm | Wheel Bore: 25mm |

| Wheel Type:9A3 | Wheel Weight:1.5kgs/PC |

Advantages of resin 9A3 diamond grinding wheel:

* High cutting efficiency, good self-sharpening, less blocking,

reducing the grinding burn occurs when the phenomenon of work

* Good flexibility will help to improve the surface roughness,

mainly used for rough grinding, semi-fine grinding,

polishing and other processes

* Compared to conventional silicon carbide , resin diamond wheel

has good material removal rates, longer wheel life and lower

grinding costs

* Resin bond diamond wheels generally remove material up to 10

times faster than metal bond wheels

Question

How to dressing the resin bond super abrasives grinding wheels?

They are usual 2 methods to dressing the resin bond super abrasives grinding wheels.

1:

Dressing by the white aluminum oxide sticks for CBN wheels,

and silicon carbide sticks for diamond wheels, it's manual as below picture.

2:

Dressing by a silicon carbide abrasive wheel on a special device with a centrifugal brake.

Contacting with the grinding wheel, the truing wheel turns, due to braking, it slips relative to the grinding wheel,

“opening” its working surface and decreasing its run-out at the same time.

Like blow picture.

The wheels are also dreessing by Diamond dresser sometimes.