ZHENGZHOU SHINE ABRASIVES CO.,LTD |

|

Verified Suppliers

|

|

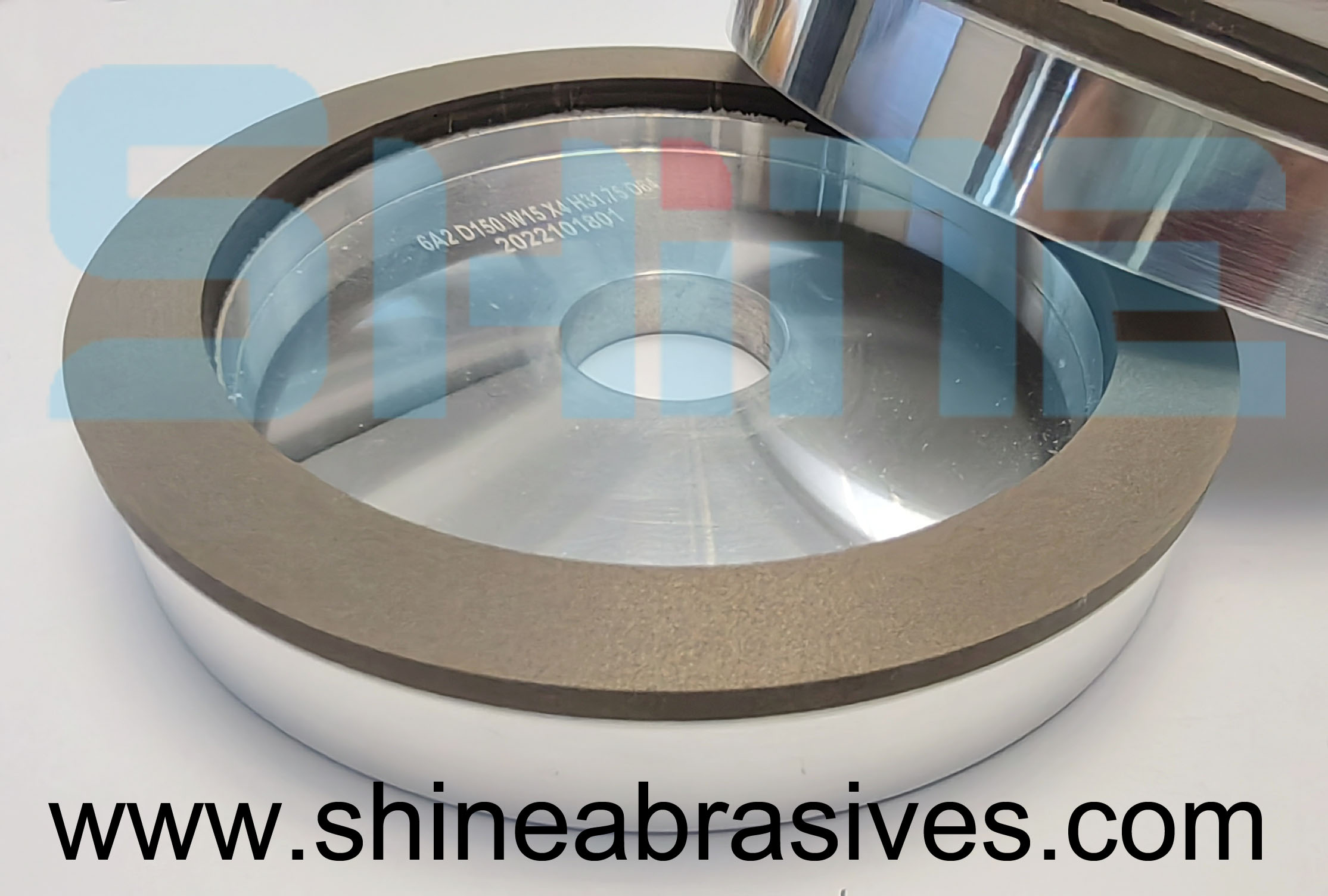

Resin bond diamond grinding wheel suits to grind carbide, hard steel, hard alloy, all kinds of serrated teeth, sharpen edges, milling cutter, Suitable for the surface grinding and outer circular grinding of cemented carbide measuring tools, tungsten steel, alloy steel.Also suit for grinding high-alumina porcelain, optical glass, agate gem, semiconductor material, stone, etc. We will provide a complete solution for tools manufacturing process, including fluting, gashing and clear edge, relief angle grinding .

Our resin bond diamond grinding wheel suits to grind carbide, hard steel, hard alloy, all kinds of serrated teeth, sharpen edges, milling cutter, Suitable for the surface grinding and outer circular grinding of cemented carbide measuring tools, tungsten steel, alloy steel. Also suit for grinding high-alumina porcelain, optical glass, agate gem, semiconductor material, stone, etc.

Uses: used for processing metal and non-metallic hard and brittle materials, such as tungsten steel, hard alloy, high speed steel, bearing steel, die steel, ceramics, glass, agate jade, semiconductor materials. For face griding, sharpening, grinding and polishing and so on .

Features: grinding sharp, not easy to plug, processing efficiency. Processing surface and edge effect, durability, long life, good shape retention.

Product details:

| Item name | 6A2 200mm Diamond cup grinding wheels for hard material with high quality |

| Type code | 6A2 |

| Abrasive material | Diamond & CBN |

| Bond | Resin/Bronze/Vitrified/Electroplated |

| wheel base | solid Alu body for Resin bond,solid #45 steel for Metal bond |

| Coarse Grit | 80#/100#/120#/140#/170#/200#/240#/270#/325# |

| Fine grit | 400#/500#/600#/800#/1000#/1200#/1500#/2000#/3000# |

| Diamond Concentration | 50%,75%,100%,125%,150% |