Briture Co., Ltd. |

|

Verified Suppliers

|

1. concrete reinforcement

2. Industrial Floor

Specification:

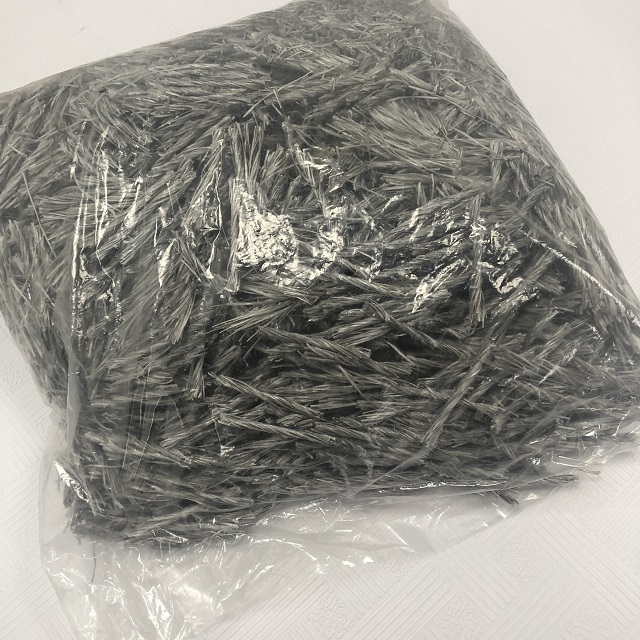

Raw Material | PP/PE | Fiber Type | Twisted Bunchy form |

Length (mm) | 40/48/50/54 | Diameter (mm) | 0.3+/-0.05 |

Strength (Mpa) | >560 | Elastic Modulus (Mpa) | >5000 |

Break tesile ratio (%) | >15 | Density (g/cm3) | 0.91 |

1. Ration design of the fiber concrete:

Generally the recommended amount to add to the concrete is more

than 2.7kg per m3(volume ratio is 0.3%), reinforcement adding

amount is 5.5kg, Compared with adding 47kg of steel fibre, 5.4kg

polymer fiber has the same volume ratio to the concrete.

2. Length: 54mm for common crack-resistant requirement.

3. Matching Ratio: Usually, it is no need to Change the matching ratio of the

concrete. Considering the requirement of fissure-resistant, the

polymer fiber is recommend to combine with the PP fiber mesh form

with the volume ratio of 1:1 (0.9kg fiber-mesh to per m3 of cement

concrete).

4. Mixer Adoption: Double-axle horizontal compelling mixer is priority.

5. Mixing process: Stones, fiber and sand are putted into the blender. After

mixing for 2 minutes, spread out the fiber, then add cement and

water and mix normally. The added material can also be added as

ordinary concrete, but the mixing time should be appropriately

extended, so that the fiber is completely mixed.

6. Shaping & Maintenance: There is no special requirement, may along the vibrating time for

30s, The maintenance of the fiber concrete should be done same as

the normal concrete.