WEIFANG BETTER CERAMICS CO.,LTD |

|

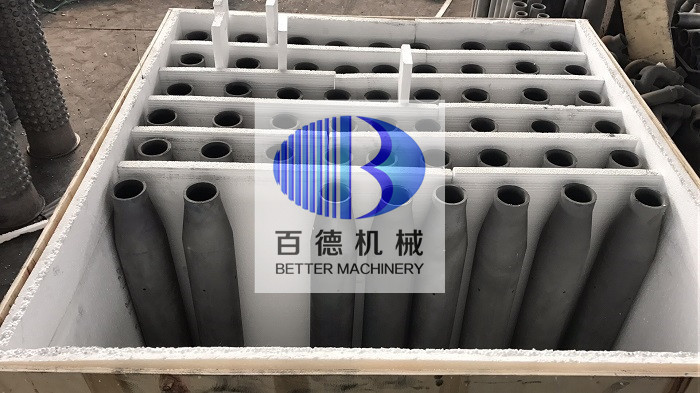

Silicon Carbide tube Ceramic Burner Nozzle Used in Kilns with good quality and different length

a)Reaction Boned Silicon Carbide(RBSiC or SiSiC) ceramics adopt slip-casting technology. The Ceramics have high strength and excellent hardness, wear, corrosion resistance, oxidization resistance and thermal shock resistance, etc. It’s one of the most popular refractory ceramics. It can be made to beams, rollers, cooling air pipes, thermal couple protection tubes, sealing parts and special shaped parts.

b)Character: High strength, extreme hardness, wear resistance, high temperature tolerance, corrosion resistance, oxidation resistance, thermal shock resistance, high thermal conductivity, low coefficient of thermal expansion, creep resistance under high temperature and so on.

c)Reaction Bonded Silicon Carbide burners are made from high quality SiC powders. They have little deformation at high temperature, low coefficient of thermal expansion, antioxidation and anticorrosion, high strength and so on. Therefore, they can be widely used in all kinds of kilns.

Usage:Used in tunnel kiln, shuttle kiln, roller hearth kiln and other industrial kiln of gas, fuel oil

What can we do for you?

1. Sample is available.

2. ISO manufacture, precise quality standards, modern logistics

management, and sound marketing strategy.

3. Inquiry replied within 24 hours.

4. Patented products.

5. OEM or ODM is available.

6. Some extra accessories can be supplied.

7.The larger quantity you order,the more competitive prices you'll

get.

8. Necessary Certificates can be supplied.

| Technical Parameter Of Reaction-Bonded SiC Products | ||

| Item | Unit | Data |

| application temperature | °C | 1380 |

| density | g/cm3 | ≥3.02 |

| open porosity | % | ≤0.1 |

| bending strength | Mpa | 250(20°C) |

| Mpa | 280(1200°C) | |

| modulus of elasticity | GPa | 330(20°C) |

| GPa | 300(1200°C) | |

| thermal conductivity | W/(m·k) | 45(1200°C) |

| coefficient of thermal expansion | K-1×10-4 | 4.5 |

| rigidity | 9 | |

| acid & alkali resistance | excellent | |