Wuxi Wellful Decoration Materials Co.,Ltd. |

|

4.0mm Thick SPC Click Flooring ,meeting room office flooring saves installation time

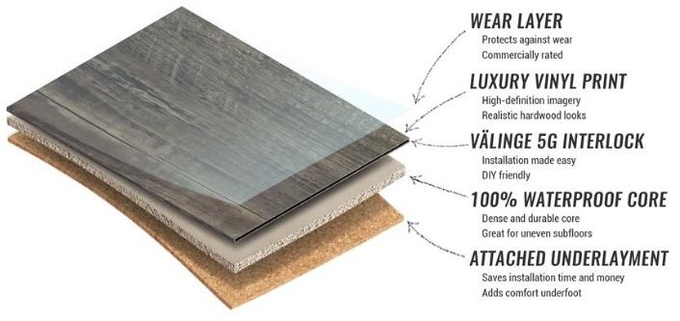

SPC is heat fused, GLUE FREE. Immediately after the high temp extrusion process the colour film is brought together and permanently fused. The next steps involve applying the wear layers, UV layers and textured embossing. Quality controlled throughout each step then cut to size. We then add the patented Valinge click system and the underlay. Our flooring saves on installation time and is great for homes, hotels, hospitals, shopping malls, and strata buildings.

Pros of SPC Flooring for the Kitchen

It boasts that highly sought-after luxurious look and feel.

SPC imitates the aesthetics of hardwood, sans the maintenance.

It has a special waterproof core that’s essential in the kitchen.

It’s durable, so it holds up well to pet nails and heavy traffic.

It’s more resilient than tile flooring, so don’t worry if you do drop something!

PVC flooring Production Process

1. Material fully mixing and feeding:

Feeding PVC material,additives(calcium carbonate),etc into mixer machine,make them fully mixing and melting.

2. Calender sheet

Adjust the thickness,Calender the fully mixed material into sheet though three cylinders,it is the base layer of PVC flooring.

Then cut,QC manager will measure the thickness and width.If not meet standards,will throw the sheet and crush it.

3. Cutting print film and wear layer

Cut the print film and wear layer into needed sizes to match the flooring size.

4. Stack up the layers:

Base layer,Print film,wear layer are stacked on top of each other

5. Hot press:

Set up the technique data according to different flooring,then Convey the stacked layers into hot press machine.The layers will be bonding seamless,we get half-finished flooring.

6. Water cooling and UV coating:

Water cooling,UV coating.This operation is used for increasing wear resistance,adjust the gloss,wax-free,more convenient to clean.

You can find me through wechat/whatsapp:+86-13057223323