Zhangjiagang Langbo Machinery Co. Ltd. |

|

Verified Suppliers

|

|

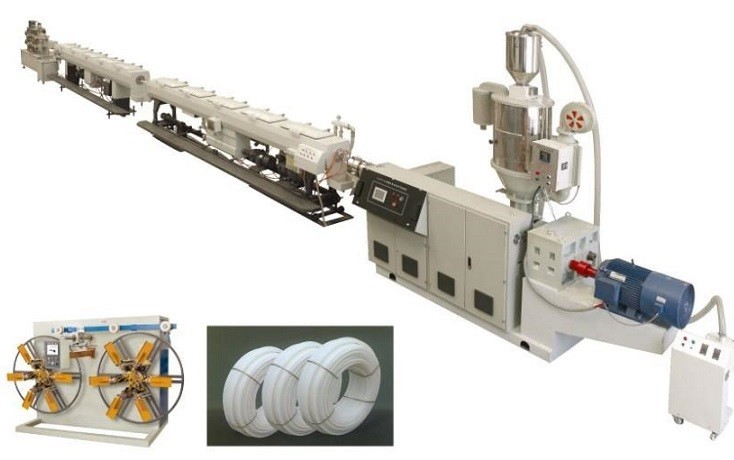

PE/PP-R Pipe Automatic Production Line Single Extrusion Line

The product application:

1. It can be used to reduce the loss of water in the field, and the irrigation water can be controlled and

regulated strictly, Integrate the field water transmission and

field irrigation control system

2. Low energy consumption, low investment, low irrigation

cost, high standard of water-saving and high efficiency,

3. The combination of pipeline water transfer and field

water-saving technology

4. Applicable conditions: suitable for field irrigation in

various types of tank areas

Features of PE pipe extrusion line

1. The extruder adopts frequency conversion control, simple

adjustment, reliable operation, stable operation

and low energy consumption. Extruder, machine head, and traction adopt one-body vertical cabinet, which is

convenient for the centralized control and operation of the whole

set of equipment.

2. The extruder screw and cylinder are made of 38CrMOAlA high-quality nitrided steel, which has been forged,

tempered and nitrogenated. The unique design has made the material plasticized with good effect and stable

production.

3. Central feed head is adopted for pipe forming, and spray cooling combined with water immersion type is

adopted for vacuum sizing with high precision, even thickness

4. Special v-type crawler tractor is adopted to ensure that the

pipe is not easy to produce traction deformation.

5, the coiling machine adopts the three-phase asynchronous torque motor controller, effectively overcome the center

tension defects, and is controlled by a separate electric cabinet, to better facilitate the independent operation,

control of the production process.

6. When producing small pipe diameter pipe, vertical hard pipe coil pipe is adopted;In the production of large

diameter pipe, the use of a pipe stack frame, with appropriate pipe cutting device, can produce different

specifications of hard pipe.

Detailed Images

| 1 | Automatic feeding machine | Vacuum feeder |

| 2 | single screw extruder | High quality desalted steel |

| 3 | Sizing method | Vacuum sizing chamber |

| 4 | water tank | water-cooling |

| 5 | dragger | Two-station tractor |

| 6 | recoiling machine | Automatic winding |