QINGDAO SINO-HOLYSON MACHINERY CO., LTD |

|

Verified Suppliers

|

|

HSJZ-53/128 PVC Wall Ceiling Panel Making Machine with Screw L/D Ratio 22 1

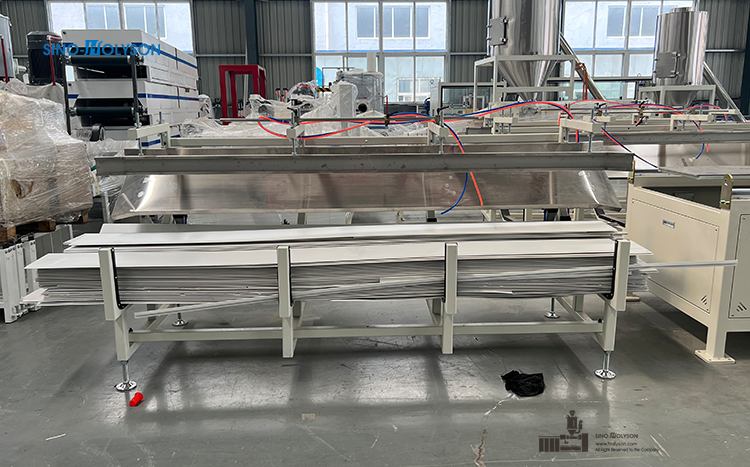

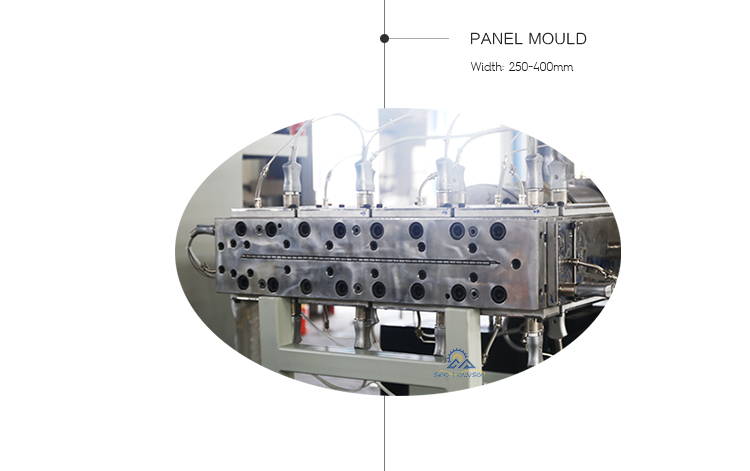

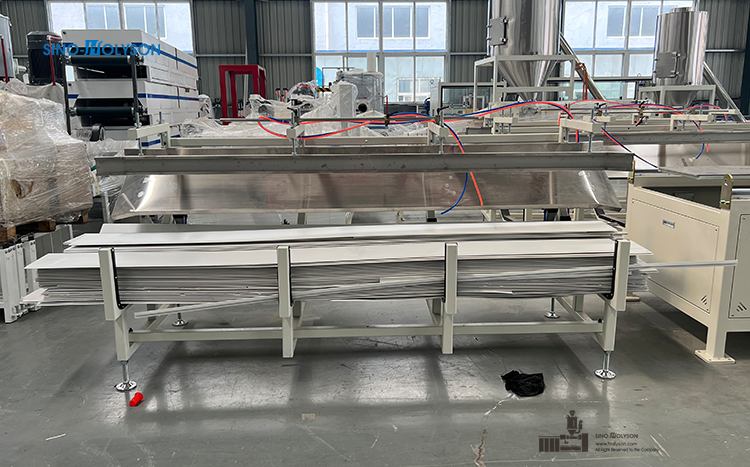

This machine is mainly designed for manufacturing both PVC Wall/Ceiling Panels and PVC U/L Angle Lines, which mainly used in home decoration; By simply replacing the mould, the machine will be flexiblly used for Wall Panels and Angle Lines production. It greatly reduce the inverster investment and improve the workshop production efficiency.

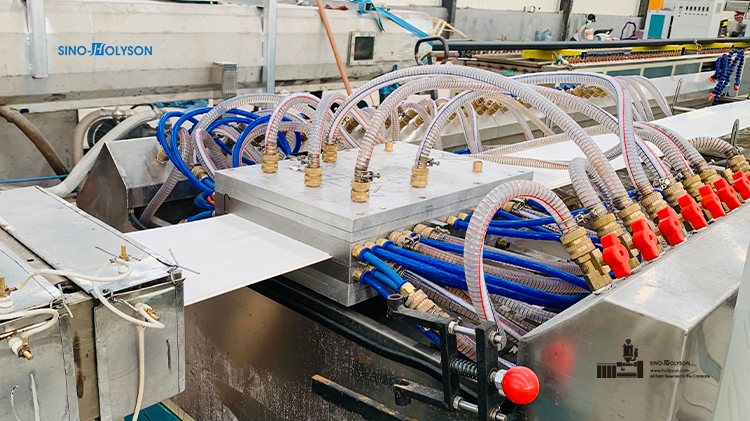

** HSJZ-53/128 Conical Twin Screw Extruder

HSJZ-53/128 Conical Twin Screw Extruder here is mainly used for PVC wall panel, PVC ceiling panel extrusion. This Extruder is designed specially for processing Higher Percent Calcium Mixed PVC Material, to manufacture PVC Wall/Ceiling Panels. The Extruder installs with 22kw driving motor, which will produce 700-1000sqm panels.

Our SCREW & BARREL Sets is specially designed for 200-260% Calcium mixed. It has the advantages of high tenacity, high impact, good bending performance, high temperature resistance, etc. The extruder extrusion output can reach 80-150kg/hr.