Dongguan Linkun Electronic Technology Co., Ltd. |

|

Verified Suppliers

|

|

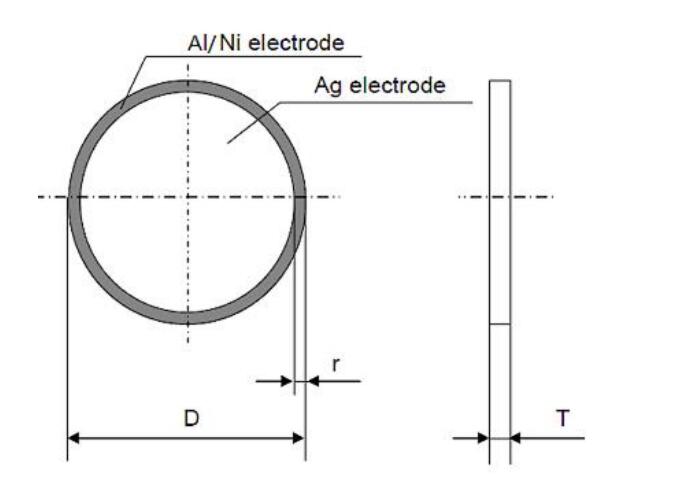

| D | 7.5士0.5 | mm |

| T | 2.0土0.5 | mm |

| r | 0-1.5 | mm |

2-1.Material of Packing | 1.Inner Foam Box 2.Carton | |||||||||||||||||||

2-2. Packing Method | 1.A carton to be placed ten foam box 2. Qty/Per Carton | |||||||||||||||||||

| 2-3. Storage Condition | Temperature : -10℃~+40℃ Humidity : ≤70%RH Term : ≤12 months (First-in/ First-out ) After unpacking of the minimum package, reseal it promptly or store it inside a sealed container with a drying agent. | |||||||||||||||||||

| Part No: MZ4P7S0820-18NV14 | PTC THERMISTOR 18Ω±30% | Rev: 0/A (Dec. 10, 19) Page 2 of 5 | ||||||||||||||||||

3. ELECTRICAL CHARACTERISTICS

| Item | Specification | Test Conditions & Methods | ||||||||||||||||||

| 3-1. Rated Zero-power Resistance (RN) | 18Ω±30% | Ambient temp. range : 25℃±1℃ Testing voltage : 1.5VDC | ||||||||||||||||||

| 3-2. Curie Temperature (TC) | 65±10℃ (for reference) | The resistance at TC is twice of RN | ||||||||||||||||||

| 3-3.Max.Operating Voltage | 14V | |||||||||||||||||||

| 3-4.Surface Temperature | 70±10℃ | At ambient Temperature : 25℃±2℃ Applying Voltage :14V Test Instruments :Digital Thermometer After applying 14V for 10minutes, test the middle of the disc temperature. | ||||||||||||||||||

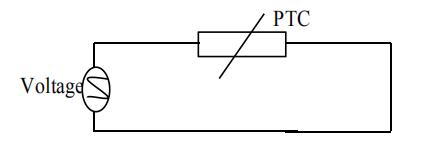

| 3-5. Withstand Voltage(Ub) (Ub) | 500V/60S | At ambient Temperature : 25℃±2℃ Test circuit diagram : PTC Voltage  | ||||||||||||||||||

| >300Ω | ||||||||||||||||||||

| 4-1. Room temperature intermittent load test | There is no abnormal appearance, structure and electrical properties. | at 25±2℃ apply 265VAC for 60sec on and 300sec off, total 1000 cycles. | ||||||||||||||||||

PTC Heater Element 170C 200C 220C 250C 220V Constant Temperature Heating Thermistor for Hair Iron Hair Straightener

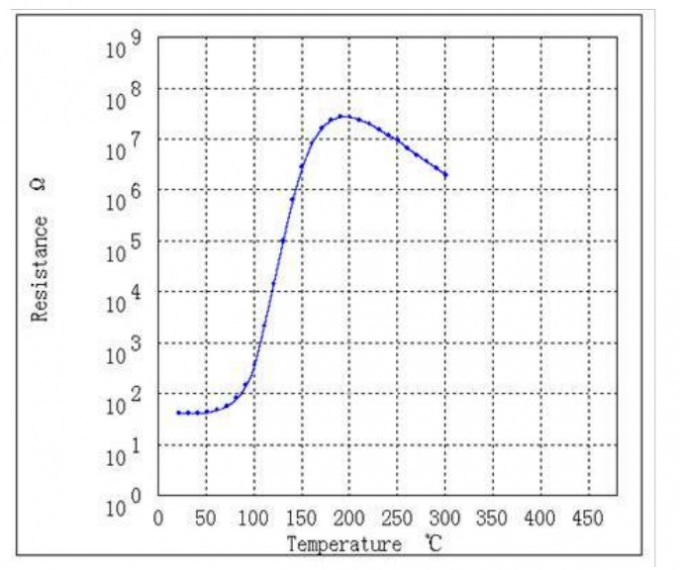

Product Description

The constant temperature heating characteristic of the PTC thermistor for constant temperature heating is determined by the material characteristics. The principle is that when the PTC thermistor is energized, the temperature of the component body rises due to self-heating, the resistance value enters the jump zone, and the current drops rapidly, so the surface temperature of the constant temperature heating PTC thermistor continues to maintain a constant value. This temperature is only related to the Curie temperature of the PTC thermistor and the applied voltage, and has nothing to do with the ambient temperature.

PTC constant temperature heater is a heating device designed by using constant temperature heating PTC thermistor constant temperature heating characteristics. In the occasion of low and medium power heating, PTC heater has the advantages of constant temperature heating, no open flame, high heat conversion rate, minimal influence of power supply voltage, long natural life and other traditional heating elements. Its application in electric heating appliances is becoming more and more popular. Favored by R&D engineers.

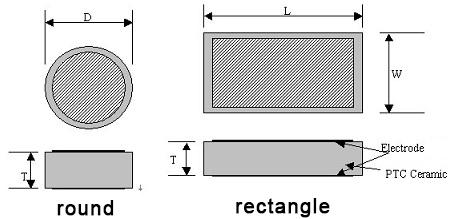

Constant temperature: The heating PTC thermistor can be made into a variety of shapes and structures and different specifications, the common ones are wafer shape, rectangle, strip shape, ring and honeycomb porous shape, etc. Combining the above-mentioned PTC heating elements and metal components can form various forms of high-power PTC heaters.

Application Design

Using constant temperature: The constant temperature heating

principle characteristics of heating PTC thermistors can be

designed and applied to hair straighteners, hair clips, hair

splints, ion perm, perm, perm board, ceramic perm board, hair

tongs, curling iron, electric comb, Negative ion hair irons,

massagers, mosquito machines, flood killers, flood repellents,

mosquito coils, perfumers, perfumers, hot melt glue guns, foot

washing heaters, glue machines, thermos cups, water boilers, coffee

machines, Coffee insulation, coffee heater, water dispenser, hot

and cold water dispenser, milk heater, water heater, shower heater,

electric mosquito repellent, hand warmer, dryer, electric hot

plate, electric soup bucket, electric soldering iron, electric

stick Combines, curling irons, showers, heaters, drying rooms,

electric heaters, electric heaters, air conditioning, air

conditioning heating, heaters, air heating, soup pots, shoe dryers,

shoe dryers, foot warmers, electric heating Plate, spectrum

analyzer, spectrum therapy, physiotherapy, infrared heating,

clothes dryer, motorcycle carburetor, electric humidifier, electric

instrument moisture-proof heating, small crystal device constant

temperature bath, constant temperature incubator, electronic

thermos, incubator, Insulation cup, insulation plate, insulation

cabinet, insulation table, electric heating plate, hyperthermia,

hot coffee machine, steam beauty, wax melting device, steam

generator, humidifier, humidifier, chocolate extruder, hot

treasure, electricity Soldering iron, acupuncture, urinary

catheter, foot warmer, hand dryer, cotton candy machine, massager,

liquefied gas cylinder heating, small warm air heater, hair dryer,

room warmer, dryer, drying cabinet, clothes dryer , Industrial

drying equipment, electric dust collector heater, train locomotive

electric heating, mold heating, control cabinet heating,

moisture-proof, moisture-proof monitor, electric oven, electric

oven, infusion treasure, medical equipment, household appliances,

household appliances, small Home appliances... etc.

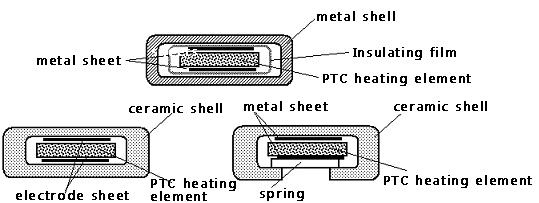

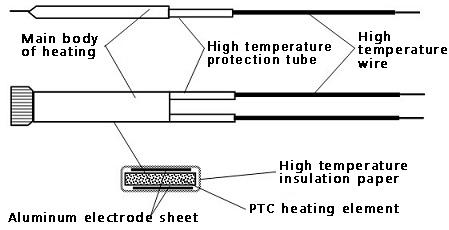

1. PTC Heating Element

Structure

Models and Parameters

| Resistance in normal temperature 25℃/Ω | Surface Temperature /℃ | Max Voltage /V | Diameter D/mm | Length L/mm | Width W/mm | Thickness T/mm | Application |

| 500~1500 | 50 | 270 | 8 | 3 | Physiotherapy | ||

| 300~800 | 85 | 140 | 16 | 11 | 2.5 | Massage equipment | |

| 150~400 | 90 | 140 | 16 | 11 | 2.5 | Massage equipment | |

| 600~1500 | 100 | 270 | 20 | 2.5 | Massage equipment | ||

| 500~1500 | 110 | 270 | 16 | 11 | 2.2 | Shoe dryer | |

| 500~1500 | 130 | 270 | 20 | 2.2 | Heating plate | ||

| 200~800 | 150 | 140 | 10.8 | 2.2 | Degaussing heating | ||

| 200~800 | 155 | 270 | 10.8 | 2.2 | Wax melter | ||

| 500~1500 | 155 | 270 | 10.8 | 2.2 | Heating plate | ||

| 1.5~5K | 170 | 140 | 5 | 4 | 1.6 | Delay switch | |

| 150~500 | 175 | 140 | 10.8 | 2.2 | Heating plate | ||

| 500~1500 | 180 | 270 | 10.8 | 2.2 | Plastic clip | ||

| 200~800 | 185 | 270 | 10.8 | 2.2 | Degaussing heating | ||

| 1~3K | 195 | 270 | 8 | 2.5 | Mosquito killer | ||

| 800~2K | 230 | 270 | 19 | 12 | 2.2 | Curling iron | |

| 800~2K | 250 | 270 | 13 | 2.5 | Mosquito killer | ||

| 2~5K | 250 | 270 | 20 | 2.5 | Water heating | ||

| 800~2K | 250 | 140 | 23.5 | 10 | 2.2 | Heating plate | |

| 800~2K | 255 | 270 | 23.5 | 10 | 2.2 | Hair straightener, heating plate | |

| 500~2K | 275 | 270 | 35 | 10 | 2.1 | Hair straightener, heating plate | |

| 300~800 | 280 | 140 | 24 | 15 | 2.5 | Air heating | |

| 0.8~3.5K | 280 | 270 | 24 | 15 | 2.5 | Air heating |

Use Attention

1) The PTC heater has the characteristics of automatic constant temperature and does not require a temperature control system. It is the core element of all PTC heaters.

2) There are four kinds of electrodes for customers to choose: electroless nickel + silver, melt-blown metal aluminum, printed aluminum + silver, printed aluminum.

3) The working voltage is very wide. When the operating voltage changes twice, the change in surface temperature is very small.

4) When multiple PTC heaters are used together, they should be connected in parallel, not in series.

5) This product has no lead wires and insulation layer. If the customer cannot use it, please choose an insulation film type product or a metal shell type product.

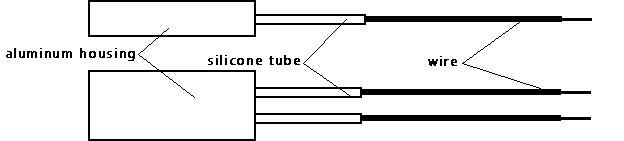

2. Metal Shell Type PTC Heater

Structure

Models and Parameters

| Length/mm | Width/mm | Thickness/mm | Surface Temperature /℃ | Insulation withstand voltage /V | Use voltage /V | Application |

| 30~120 | 20 | 5.0 | 60~280 | 3750 | 100~240 | Constant temperature heating |

| 30~120 | 30 | 6.0 | 60~280 | 3750 | 100~240 | Constant temperature heating |

| 30~120 | 33 | 7.0 | 60~280 | 3750 | 100~240 | Constant temperature heating |

| 30~120 | 35 | 7.0 | 60~280 | 3750 | 100~240 | Constant temperature heating |

| 30~120 | 40 | 7.0 | 60~280 | 3750 | 100~240 | Constant temperature heating |

| 30~120 | 43 | 7.0 | 60~280 | 3750 | 100~240 | Constant temperature heating |

| 30~120 | 46 | 7.0 | 60~280 | 3750 | 100~240 | Constant temperature heating |

| 30~120 | 56 | 7.0 | 60~280 | 3750 | 100~240 | Constant temperature heating |

According to customer requirements, the temperature can be designed between 60°C and 280*C, and the operating voltage can be designed between 12V and 240V.

Use Attention

1) The heating power increases from large to small after power-on,

and finally stabilizes. The stable power is related to the use

conditions. For the same PTC heater, the power may be several times

different if the use conditions are different. The faster the heat

dissipation, the greater the stable power; the higher the surface

temperature of the PTC, the higher the power.

2) The surface temperature of the PTC heating element is controlled

by the PTC itself, or it can be controlled by disconnecting the

circuit, but the surface temperature cannot be controlled by

adjusting the voltage.

3) PTC itself is highly reliable and has a long life span. However,

if the product is improperly assembled, the power and temperature

of the product will be unstable.

4) When multiple PTCs are used together, they should be connected

in parallel, not in series.

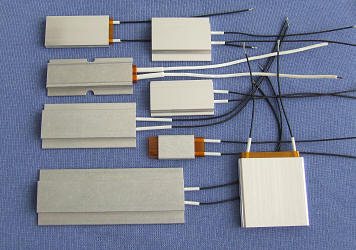

3. Insulating Film Type PTC Heater

Structure

Models and Parameters

| Length/mm | Width/mm | Thickness/mm | Surface Temperature /℃ | Insulation withstand voltage /V | Use voltage /V | Application |

| 24 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 24 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 35 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 35 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 35 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 35 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 48 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 48 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 48 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 48 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 60 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 60 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 60 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 60 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 70 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 70 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 70 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| 70 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

| Above 70 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 | Constant temperature heating |

According to customer requirements, the temperature can be designed between 50^C and 280C, and the operating voltage can be designed between 3V and 240V.

Use Attention

1) The heating power increases from large to small after power-on,

and finally stabilizes. The stable power is related to the use

conditions. For the same PTC heater, the power may be several times

different if the use conditions are different. The faster the heat

dissipation, the greater the stable power; the higher the surface

temperature of the PTC, the higher the power.

2) The surface temperature of the PTC heating element is controlled

by the PTC itself, or it can be controlled by disconnecting the

circuit, but the surface temperature cannot be controlled by

adjusting the voltage.

3) PTC itself is highly reliable and has a long life span. However,

if the product is improperly assembled, the power and temperature

of the product will be unstable.

4) When multiple PTCs are used together, they should be connected

in parallel, not in series.