Shenzhen Sky-Win Technology Co., Ltd |

|

Verified Suppliers

|

|

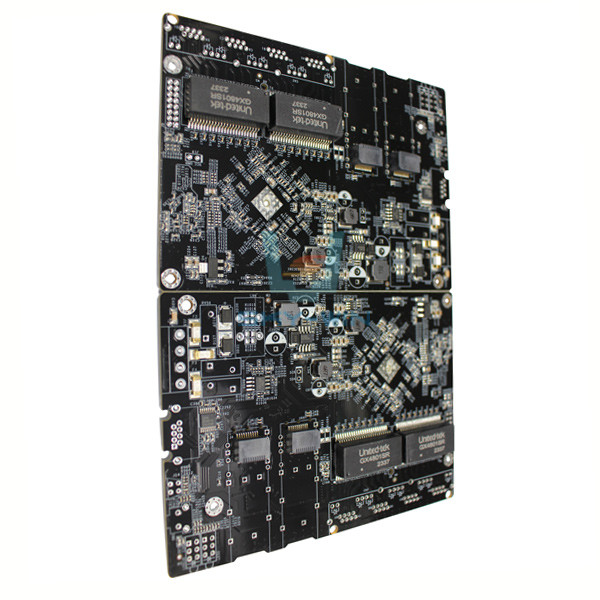

Single/Double-Sided Black Solder Mask Medical PCB Assembly 2mm Thickness With Lead Time 3-5 Business Days

Medical PCB Assembly Description

In the medical field, electronic devices must be designed with precision and accuracy, ensuring they can last for a long time and that reliability is guaranteed. For devices that include a printed circuit board (PCBs) excessive care is needed to ensure all the required quality and sanitation control standards are met.

At our company, we take strict measures during the PCB assembly process, to ensure our PCBs meet all the given standards. In the end, our products guarantee medical devices that are efficient and most importantly, safe to use.

Medical PCB Assembly Features

Medical PCB assembly services are an important part of manufacturing reliable and high-quality printed circuit boards (PCBs) for medical device applications. Not only do they provide invaluable expertise in areas such as compliance, quality control and testing, they also ensure that the assembled PCBs meet the strict standards and regulations of the medical industry.

Medical PCB assembly services also offer design for manufacturability (DFM) reviews to optimize the PCB design. This ensures the design is compatible with the assembly process, minimizing potential manufacturing issues and maximizing the reliability and performance of the medical device. Components are sourced from trusted suppliers to meet the required quality and reliability standards.

Rigorous quality control and testing processes are also implemented throughout the assembly process. This includes procedures such as automated optical inspection (AOI), in-circuit testing (ICT), functional testing, and environmental testing. Regulatory documentation and support are also provided to ensure successful regulatory audits and approvals.

What's more, medical PCB assembly services understand the diverse needs of the medical industry and offer flexibility and customization options. This can include special material requirements, unique form factors and other considerations for medical devices.

In short, medical PCB assembly services are essential to the medical industry. Their specialized knowledge and technological capabilities ensure that PCBs are manufactured to the highest quality standards, contributing to the development of safe and effective medical products.

Medical PCB Assembly Parameters

Power Supply Mode | Built-in Battery |

Finish Treatment | HASL Lead Free,Immersion Gold,ENIG 3u'' |

Bga Pitch | 0.3 Mm ~3.0 Mm |

Assembly Details | SMT And Thru-hole, ISO SMT And DIP Lines |

Dielectric Thickness | 0.05mm, 0.075mm, 0.1mm, 0.15mm, 0.2mm |

Thickness | 1.6-3.2mm |

Test Service | E-test/AOI/X-RAY/Function Test |

Lead Time | 3-5 Business Days |

PCBA Design | Base On Your Request |

Layer | 2-32L |

Specialty | Healthcare Device PCB Assembly, Medical Equipment Assembly Board, Health Electronics PCB Assembly |

Applications of Medical PCB

Over the years, we have developed expertise as one of the experienced medical PCB manufacturers, and designed and manufactured a variety of PCBs for different medical electronic applications. Our medical PCBs are used in a wide range of applications, such as X-ray computed tomography, CT scan systems, infusion fluid control, peristaltic infusion technology, ultrasonic technology, neurological stimulus, heart pacemakers, body temperature devices, EMG activity systems, blood glucose monitors, heart monitors, vesicle pressure measurement, flow rate and dispensing systems and blood pressure monitors. We strive to provide PCBs to meet all medical electronic requirements with the highest level of quality.

Packaging and Shipping for Medical PCB Assembly

The medical PCB assembly should be packaged carefully to protect it from any external damage during shipping. Depending on the size and type of the assembly, it can be packaged in a bubble wrap, foam, or other protective material. All packages should be sealed to ensure that the product remains safe and secure throughout transit.

The product should be shipped with a reliable carrier such as UPS, FedEx, or USPS. The shipping option chosen should be based on the size, weight, and destination of the package. If the package is fragile or sensitive, it is recommended to use a more secure shipping option with tracking and insurance.