Shenzhen Sky-Win Technology Co., Ltd |

|

Verified Suppliers

|

|

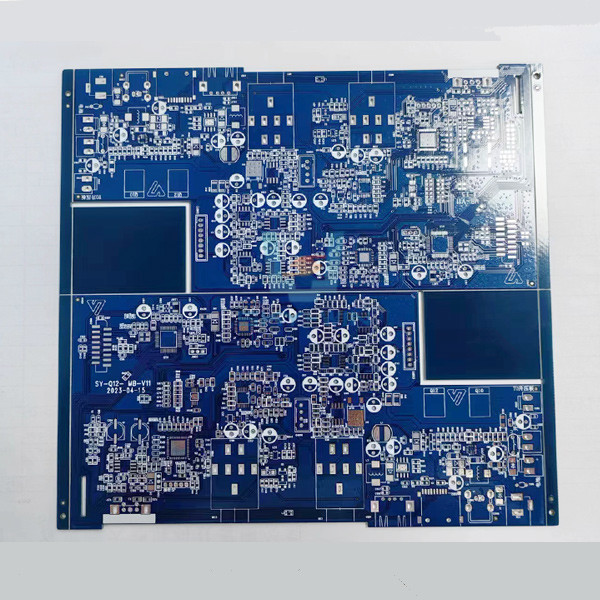

Custom Electronic SMT FR4 Multilayer PCBs Prototype Black White Silk Screen PCB Assembly

SMT Stencil Used In The PCB Design

Surface Mount Technology (SMT) templates are made of a thin,

flexible material with openings corresponding to the pads of the

components and holes in the PCB. The opening in the template allows

conductive ink to flow during PCB etching. They are a great way to

quickly and accurately apply solder paste to the pad on the circuit

board. PCB templates help save money, improve quality and speed up

the manufacturing process. Templates can be used for single or

multi-layer boards, as well as multi-layer large boards. At Sky

Win, we offer a wide range of rugged SMT Stencils to suit your

specific manufacturing needs, manufacturing methods and components

used in your board.

SkyWin SMT Assembly Capability

We have the capabilities to assemble SMT prototype PCBs in small

production runs with manual and/or automated SMT production

processes, including single- or double-sided component insertions.

Our production facilities can assemble the following SMT types:

Ball Grid Array (BGA)

Ultra-Fine Ball Grid Array (uBGA)

Quad Flat Pack No-Lead (QFN)

Quad Flat Package (QFP)

Small Outline Integrated Circuit (SOIC)

Plastic Leaded Chip Carrier (PLCC)

Package-On-Package (PoP)

Small Chip Packages (0.2mm pitch )

Main SMT Machines in PCBWay

Automatic Solder Paste Printer

Reflow Soldering Machine

Pick & Place Machine

Manufacturing Capabilities: PCB Assembly Manufacturer, Solder Paste Printing, Reflow Soldering, AOI, and X-ray Inspection

SMT PCB Assembly Technical Parameters

| Product Name | PCB & PCBA |

| Material | FR4, CEM1, CEM3, High Frequency Board, |

| Layer | 1,2,4,6...20Layer |

| Shape | Retangular, Round, Slots, Cutouts, Complex, Irregular |

| Cutting | Shear, V-score, Tab-routed |

| Board Thickness | 0.2-4mm, regular 1.6mm |

| Copper Thickness | 0.5-4oz, regular 1oz |

| Solder Mask | Green, Red, Blue, Yellow, etc. |

| Silk Screen | White, Black, etc. |

| Silk Screen Min Line Width | 0.006" or 0.15mm |

| Min Trace/Gap | 0.1mm or 4mils |

| Min Drill Hole Diameter | 0.01",0.25mm or 10mils |

| Surface Finish | HASL, ENIG, OSP, etc. |

SMT PCB Assembly Capacity:

| Items | PCBA capacity |

| Product name | SMT circuit board manufacturer custom electronic assembly pcb pcba |

| Assembly details | SMT and Thru-hole, ISO SMT and DIP lines |

| Testing on products | Testing jig/mold , X-ray Inspection, AOI Test, Functional test |

| Quantity | Min quantity : 1pcs. Prototype, small order, mass order, all OK |

| Files needed | PCB : Gerber files(CAM, PCB, PCBDOC) |

| Components : Bill of Materials(BOM list) | |

| Assembly : Pick-N-Place file | |

| PCB Panel Size | Min size : 0.25*0.25 inches(6*6mm) |

| Max size : 1200*600mm | |

| Components details | Passive Down to 0201 size |

| BGA and VFBGA | |

| Leadless Chip Carriers/CSP | |

| Double-sided SMT Assembly | |

| Fine BGA Pitch to 0.2mm(8mil) | |

| BGA Repair and Reball | |

| Part Removal and Replacement | |

| Component package | Cut Tape, Tube, Reels, Loose Parts |

| PCB+ assembly process | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity |

SMT PCB Assembly Manufacturer

Shenzhen SKY-WIN Technology Co., Ltd was founded in February 2015, focusing on PCBA OEM/ODM one-stop service, solution customization, SMT patch, DIP plug-in, functional testing, assembly and other OEM/ODM services.

SMT PCB Assembly Inspection Necessity

In order to ensure the quality and performance of the assembled

PCB, it is very necessary to check during the entire SMT assembly

process. Multiple types of inspections must be used to reveal

manufacturing defects, which can reduce the reliability of the

final product.

Visual inspection is most commonly used in SMT patch assembly. As a

direct inspection method, visual inspection can be used to indicate

obvious physical errors, such as component displacement, missing

components, or component irregularity.

Visual inspection is not suitable for visual inspection. Tools such

as a magnifying glass or microscope can also be used. In order to

further point out the defects occurring in the welding ball, AOI

and X-ray inspection can be used after the completion of coal

bonding