Active Member

|

[China]

Address: Room 1520, Block 11, International E-Commerce Logistics Center, PingAn Road, PingHu Street, LongGang District, ShenZhen City, China 518111

Contact name:Steven YU

Witgain Technology Limited |

|

10 Layer Printed Circuit Board 1.6MM Thickness Green Solder Mask

Main Features:

1 10 Layer customized printed circuit board manufacturered based on customer's gerber files.

2 Used in Motor areas.

3 Material is FR4 S1000-2 TG170.

4 The finished board thickness is 1.6MM.

5 The finished copper thickness is 35UM.

6 Surface treatment is ENIG 2U'.

7 Drilling: L1-L10 0.2MM

8 Lead time is around 20 working days.

FQA:

Q1: What is HASL - Hot Air Solder Leveling?

A1:

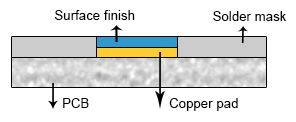

HASL (Hot Air Solder Leveling) is a metallic surface finishing technique, which is performed on the outermost layer of the PCB board to protect the exposed copper surfaces like tracks until the component placement and soldering is completed.

The HASL coating is composed of Solder with 63% Tin and 37% Lead, and during the assembly process, this coating gets dissolved with the soldering material.

The HASL Coating is applied as per the steps below:

Advantages of HASL:

Limitations of HASL: