Qingdao National Premium Oilwell Machinery Co.,Ltd |

|

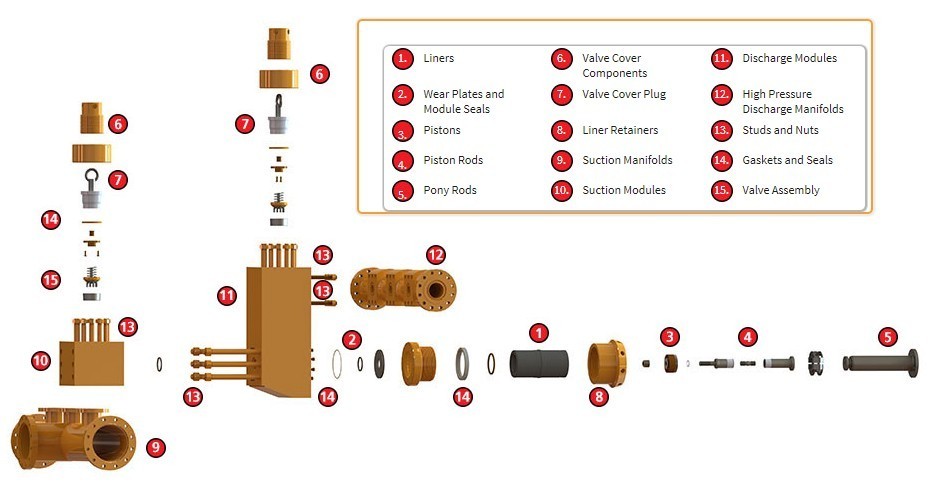

Southwest Oilfield Products, Inc. manufacture rugged and reliable equipment for specific needs including Mud Pump Fluid Ends, Frac Pump Fluid Ends, Liners, Pistons and other consumable items.

Premium have delivered solid cost savings to our customers. This is due to our lower cost base, system with access to identical parts directly from manufacturer, and utilizing our experienced drilling equipment employees at very competitive rates.

Below selection of popular identical mud pump parts that can be supplied by Premium at major cost savings:

Premium can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Premium is an independent supplier of drilling equipment parts.

Premium is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Premium to cause confusion as to the source, sponsorship, or quality of the parts supplied by Premium. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Premium’s supply of parts.

| NATIONAL 9-P-100 | |||

| FLUID END MODULE & ACCESSORIES | |||

| ITEM # | TSC PART # | DESCRIPTION | WEIGHT |

| 1 | TS-1293240 | MODULE, STUDDED FLUID END DISCHARGE ( INCLUDES ITEMS 1,3-6, 9-11, 30&31) | 1365 |

| 2 | TS-1290338 | MODULE, STUDDED FLUID END SUCTION (INCLUDES ITEMS 2,3,4 ) | 680 |

| 3 | TS-2408019 | STUD, THREADED RING | 3.12 |

| 4 | TS-6300220 | NUT, THREADED RING STUD | 0.74 |

| 5 | TS-2408030 | STUD, POWER FRAME | 1.75 |

| 6 | TS-6300200 | NUT, POWER FRAME STUD | 0.5 |

| 7 | TS-2402560 | STUD,TOP TAPER LOCK (FOR BLIND RING AND WELD NECK FLANGES) | 1.75 |

| 8 | TS-6300200 | NUT, STUD (BLIND RING AND WELD NECK FLANGES) | 0.5 |

| 9 | TS-2408034 | STUD, DISCHARGE MODULE TO SUCTION MODULE | 9.5 |

| 10 | TS-6300241 | NUT, DISCHARGE TO SUCTION MODULE STUD | 0.94 |

| 11 | TS-6511416 | PIN, DOWELL | 0.5 |

| 12 | TS-1292141 | BUSHING,VALVE GUIDE | 1 |

| 13 | TS-1292140 | RETAINER, VALVE GUIDE BUSHING | 1 |

| 14 | TS-1540126 | GASKET, VALVE COVER | 0.2 |

| 15 | TS-1290174 | RETAINER, SEAL | 38 |

| 16 | TS-1290178 | SCREW, ADJUSTING WEDGE | 3 |

| 17 | TS-G-1290376 | ASSEMBLY, WEDGE (INCLUDES ITEM #18 WEDGE SPRING) | 7 |

| 18 | TS-1290181 | SPRING, WEDGE | 1 |

| 19 | TS-1290308 | RING, THREADED | 77 |

| 20 | TS-1290307 | CAP, VALVE COVER (THREADED) | 70 |

| 21 | TS-1290315 | WASHER, WEDGE ADJUSTING SCREW | 0.15 |

| 22 | TS-6300160 | NUT, WEDGE ADJUSTING SCREW | 0.5 |

| 23 | TS-2410031427 | SEAL,DISCHARGE CONNECTOR & DISCHARGE ADAPTER | 0.05 |

| 24 | TS-1290343 | ADAPTER, DISCHARGE CONNECTOR | 5 |

| 25 | TS-2410031348 | SEAL,DISCHARGE CONNECTOR TO DISCHARGE ADAPTER | 0.05 |

| 26 | TS-1290342 | CONNECTOR, DISCHARGE | 16.75 |

| 27 | TS-700030511 | CAPSCREW, DISCHARGE CONNECTOR (WASHER INCLUDED) | 0.05 |

| 28 | TS-1290357 | PLATE, WEAR | 10 |

| 29 | TS-1293165 | BUSHING, LINER(SAME AS 8P-80 & 10P-130) | 110 |

| 30 | TS-2408018 | STUD, LINER BUSHING | 1.2 |

| 31 | TS-6300160 | NUT, LINER BUSHING STUD | 0.5 |

| 32 | TS-1293166 | ASSEMBLY, LINER CLAMP (INCLUDES ITEMS 32,33,34,35,36,37) | 150 |

| 33 | TS-7000448-11 | CAPSCREW, LINER CLAMP | 0.05 |

| 34 | TS-6309120 | NUT, LINER CAPSCREW | 0.12 |

| 35 | TS-1290169 | PIN, CONNECTOR | 0.15 |

| 36 | TS-1290168 | CONNECTOR, LINER CLAMP | 0.2 |

| 37 | TS-6571420 | PIN, SPRING | 1 |

| 38 | TS-1290344 | SEAL, MODULE & WEARPLATE | 0.2 |

| 39 | TS-1590051 | SEAL, SUCTION MANIFOLD | 0.2 |

| GARDNER DENVER PZ-10, PZ-11 | |||

| FLUID END MODULE & ACCESSORIES | |||

| ITEM # | TSC PART # | DESCRIPTION | WIGHT |

| 01 | TS-202PZL029B | FLUID END MODULE STUDDED (INCLUDES 1-8) | |

| 02 | TS-201PZL110 | STUD, FRAME & LINER CLAMP LONG | |

| 03 | TS-205PZL110 | STUD, SHORT | |

| 04 | TS-50B36 | NUT, FRAME & LINER CLAMP STUD | |

| 05 | TS-204PZL110 | STUD | |

| 06 | TS-50B34 | NUT (FOR ABOVE) | |

| 07 | TS-202PZL110 | STUD, DISCHARGE MANIFOLD | |

| 08 | TS-50B34 | NUT (FOR ABOVE STUD) (SAME AS ITEM 6) | |

| 09 | TS-200PL387 | RING, VALVE COVER THREADED | |

| 10 | TS-204PZL715(G-798Z) | GASKET, VALVE COVER | |

| 11 | TS-2007674 | BUSHING, VALVE GUIDE | |

| 12 | TS-200PZL147 | COVER, VALVE | |

| 13 | TS-25AL37(G-692) | LINER GASKET | |

| 14 | TS-200PZL587 | CAP, VALVE COVER LOCK | |

| 15 | TS-2011701 | PLATE, RETAINER | |

| 16 | TS-200PZL483 | GUIDE, VALVE SUCTION | |

| 17 | TS-95W2 | WASHER, LOCK 1/2" 316SS | |

| 18 | TS-655EE065 | SCREW 1/2" x 1 3/4" 316SS HX HD C/S | |

| 19 | TS-25AL35 | GASKET, DISCHARGE MANIFOLD | |

| 20 | TS-25G41 | GASKET, SUCTION MANIFOLD | |

| 21 | TS-200PZL455 | CLAMP, LINER | |

| 22 | TS-200PZL483A | ASSY., LOWER VALVE GUIDE ( INCLUDES ITEMS 15-18.) |

| GARDNER DENVER PZ-7, PZ-8, PZ-9 | |||

| FLUID END MODULE & ACCESSORIES | |||

| ITEM # | TSC PART # | DESCRIPTION | WEIGHT |

| 01 | TS-205PZL029D | FLUID END MODULE STUDDED (INCLUDES 1-9 ) | |

| 02 | TS-79L188 | STUD, FRAME & LINER CLAMP | |

| 03 | TS-50B36 | NUT (FOR ABOVE) | |

| 04 | TS-79L73 | STUD, FRAME | |

| 05 | TS-50AQ30 | NUT (FOR ABOVE) | |

| 06 | TS-79AL6 | STUD, VALVE COVER | |

| 07 | TS-50B34 | NUT (FOR ABOVE) | |

| 08 | TS-202PZL110 | STUD, DISCHARGE MANIFOLD | |

| 09 | TS-50B34 | NUT (FOR ABOVE) | |

| 10 | TS-2011861 | RING, VALVE COVER GASKET EXPANDER | |

| 11 | TS-2011862(G-749) | GASKET, VALVE COVER | |

| 12 | TS-2007674 | BUSHING, VALVE GUIDE | |

| 13 | TS-2011860 | COVER, VALVE | |

| 14 | TS-2011699 | RING, VALVE COVER THREADED | |

| 15 | TS-2011857 | CAP, VALVE COVER LOCK | |

| 16 | TS-2011701 | PLATE, RETAINER | |

| 17 | TS-2011700 | GUIDE, VALVE SUCTION | |

| 18 | TS-95W2 | WASHER, LOCK 1/2" 316SS | |

| 19 | TS-655EE06S | SCREW 1/2"x1 3/4" 316SS HX HD C/S | |

| 20 | TS-25AL35 | GASKET, DISCHARGE MANIFOLD | |

| 21 | TS-25G41 | GASKET, SUCTION MANIFOLD | |

| 22 | TS-1PV14 | CLAMP, LINER | |

| 23 |

Southwest Oilfield Products’ two-piece L-shaped fluid-ends have

become the recognized standard.

The L-shaped two-piece fluid-end was adopted into the market over 35 years ago because it was an obvious improvement over one piece modules. Since the suction module is separate from the discharge module, it is possible to replace the suction module when it wears out instead of replacing the entire fluid end.

Changing valves or seats on a two piece module is also much easier, safer and faster than changing valves or seats on a one piece module.

Southwest’s L-shaped fluid-end is manufactured from heat-treated 4130 forgings and equipped with our quick-change valve cover system; our L-shaped modules offer unmatched performance.

Southwest’s second to none manufacturing is backed by the best warranty on the market.

Advanced Zirconia Liners are significantly harder than hardened steel liners, and are tougher than any otherceramic available. The ceramic used in these liners are extremely resistant to corrosion and heat.

Zirconia is more than 25% harder than Chromium alloys which results in asignificantly lower wear rate oftheliner sleeve. Considering the smoother surface, piston life is greatly extended. In a past case study, apump with Chromium liners used 55 pistons over the test period compared to only 12 pistons used in the pump outfitted with Zirconia liners. Piston savings along exceeded $8,000 not to mention reduced maintenance downtime.

Traditional liner hourly cost is approximately $1.05 per hour, while Zirconia Liners are approximately $.23 per hour.

For use in today’s higher pressure and faster stroking triplex pumps, Grayloy liners are made of the highest quality high-chrome premium alloy steel. They are manufactured to provide maximum runs at minimal cost.

Over 60 years ago, Southwest Oilfield Products was founded on mud pump piston innovation and we continue to carry this legacy forward with the introduction of our Bulldog piston. This rugged and reliable piston is engineered for high temperature service and other demanding drilling conditions. Key features include:

BullDog Piston Part Numbers | |||||

4.5" | 5.0" | 5.5" | 6.0" | 6.5" | 7.0" |

78BDB | 81BDB | 83BDB | 85BDB | 87BDB | 89BDB |

In 1947, the first bonded piston was introduced into the market; since then, the Fail-safe piston has remained virtually unchanged. The one-piece bonded piston design eliminates leakage points and is resistant to abrasive fluids. This fail-safe piston seals off to greater diameters as the liner wears.

Fail-Safe Piston Part Numbers | ||||||

4" | 4.5" | 5" | 5.5" | 6.0" | 6.5" | 7.0" |

76BFS | 78BFS | 81BFS | 83BFS | 85BFS | 87BFS | 89BFS |

This premier piston has been in service since 1985, providing unmatched performance under extreme drilling conditions. It performs well in exotic drilling fluids and moderate temperatures.

Made of dual-durometer polyurethane, this piston is designed to resist extrusion thus extending the life of the piston.

Dual-Duro Piston Part Numbers | ||||||

4" | 4.5" | 5.0" | 5.5" | 6.0" | 6.5" | 7.0" |

76BDD | 78BDD | 81BDD | 83BDD | 85BDD | 87BDD | 89BDD |

Southwest’s RnR Piston is a renewable rubber piston in that the rubber on this non-bonded piston can be replaced by a new piston rubber once the old one has reached its usable life. The proprietary blend of rubber and fabric used in the RnR piston resists the pinching and extrusion that commonly occurs in the heel of the piston. The use of synthetic fabric in the Southwest RnR piston virtually eliminates the loss of heel strength, caused by water absorption allowing the piston to achieve a higher level of performance compared to competing designs.

Full traceability is provided with all products sold, including pistons. Traceability markings include: operators ID, packers ID, date of urethane pour, part number of piston, work order number, Made in USA brand, and SWOP logo.

Southwest's Black Cat piston is a premier nitrile-compound piston that can be utiized in a variety of drilling muds. Developed to handle the numerous chemicals found in drilling mud today, the Black Cat piston elastomer has excellent abrasion, chemical and heat resistance.

Black Cat Piston Part Numbers | ||||||

4" | 4.5" | 5" | 5.5" | 6.0" | 6.5" | 7.0" |

76BBC | 78BBC | 81BBC | 83BBC | 85BBC | 87BBC | 89BBC |

Brewster ® Mud Pumps B-550 • B-750 • B-1000 • 1100T • B-1300

Continental Emsco ® Mud Pumps F-350 • F-500 • F-650 • F-800 • F-1000 • FA-1300 • FB-1600 FB1600

Gaso ® Mud Pump 1563 • 1740-55 • 1844-60 • 2010-50 • 2200-49 • 2651 • 2652

Gardner Denver ® Mud Pumps

PAH • PZ-7 PZG • PZ-8 PZH • PZ-9 PZJ • PZ-10 PZK • PZ-11 PZL

Gardner Denver ® Well Service TEE • PE-5 • PA-8 • PAH • PJ-8 • TGF-225

Gardner Denver ® Continuous Duty GD-55T • GD-60T • GD-100T • GD-125T • GD-150T • GD-180T • GD-200T

Ideco ® Mud Pumps MM-200 • MM-300 • MM-500 • MM-500F • MM-550

Ideco ® Mud Pumps MM-550F • MM-700 • MM-700F • T-500

Ideco ® Mud Pumps T-500 • T-800 • T-1000 • T-1300 • T-1600

National ® J Series Mud Pumps J-30 • J-60 • J-100 • J-165 • J-275 • J-375 • J-625 • JWS-340 • JWS-400

National ® Mud Pumps K-280 • K-380 • K-500 • K-500A • K-700A

National ® P Series Mud Pumps 7P-50 • 8P-80 • 9P-100 • 10P-130 • 12-P-160 / 12P-160 / 12P160

Oilwell ® Mud Pumps A-350-PT • 560-PT • A-560-PT • 850-PT • A-850-PT • 1100-PT

Oilwell ® Mud Pumps A-1100-PT • 1400-PT • A-1400-PT • 1700-PT • A-1700-PT / A1700-PT

Oilwell ® Plunger Pumps C-323 through B-558 • SA-640-50 through SB-644-B

OPI ® Mud Pumps 350-D • 00-DL • 700-HDL • 1000-HDL

Wheatley ® Mud Pumps 1036 • 6070 • 7024 • 7036

Fluid End Modules

National® - Oilwell® - Continental Emsco® - Gardner Denver® - Ideco® - Skytop Brewster®

Pulsation Dampener

Hydril Type "K" Pulsation Dampener

Popular Mud Pump Spare Parts

Mud Pump Manufactures and Models include:

Brewster Mud Pumps

B-550 | B-750 | B-1000 | 1100T | B-1300

Continental Emsco Mud Pumps

FF-FXF | FG-FXG (A thrugh L) | FD-FXX | FC-FXX | FD-FXD | FC-FXD | FY-FXD

Continental Emsco Mud Pumps

GP-GXP | GR-GXP | GP-GXR | GR-GXR |PA-8 | PAH

Continental Emsco Mud Pumps

PJ8 | PZ-7 | PZ-8 | PZ-9 | PZ-10 | PZ-11 | PXL

Ellis Williams (Luko) Mud Pumps

WW-440 | 14W-400 | 15W-600 | 9W-1000

Gaso Mud Pump

1563 | 1740-55 | 1844-60 | 2010-50 | 2200-49 | 2651 | 2652

Gardner Denver Mud Pumps

FF-FXF;FG-FXG;A thru L FD-FXX FC-FXX FD-FXD FC-FXD FY-FXD GP-GXP GR-GXP GP-GXR GR-GXR PA-8 PJ8 PZ-7 PZ-8 PZ-9 PZ-10 PZ-11 PXL

Ideco Mud Pumps

MM-200 | MM-300 | MM-500 | MM-500F | MM-550

Ideco Mud Pumps

MM-550F | MM-700 | MM-700F | T-500

Ideco Mud Pumps

T-800 | T-1000 | T-1300 | T-1600

National Mud Pumps

C-150 | C-250 | C-350 | E-500 | E-700 | G-700 | G-1000

National Mud Pumps

K-280 | K-380 | K-500 | K-500A | K-700A

National Mud Pumps

7P-50 | 8P-80 | 9P-100 | 10P-130 | 12P-160

Oilwell Mud Pumps

6P-HD | 610-P | 212-P | 214-P | 218-P

Oilwell Mud Pumps

350-PT | 560-PT | A-560-PT | 850-PT | A-850-PT | 1100-PT

Oilwell Mud Pumps

A-1100-PT | 1400-PT | A-1400-PT | 1700-PT | A-1700-PT

OPI Mud Pumps

350-D | 700-HDL | 1000-HDL

Wheatley Mud Pumps

1036 | 6070 | 7024 | 7036

Wilson Mud Pumps

600 | 900